Wheeled three-dimensional mobile support flexible tooling structure

A three-dimensional mobile, flexible tooling technology, applied in the directions of supports, manufacturing tools, positioning devices, etc., can solve the problems of insufficient flexibility of flexible tooling structure layout, improve the speed of lattice layout of support columns, make up for high manufacturing costs, and simplify installation. and the effect of wiring work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

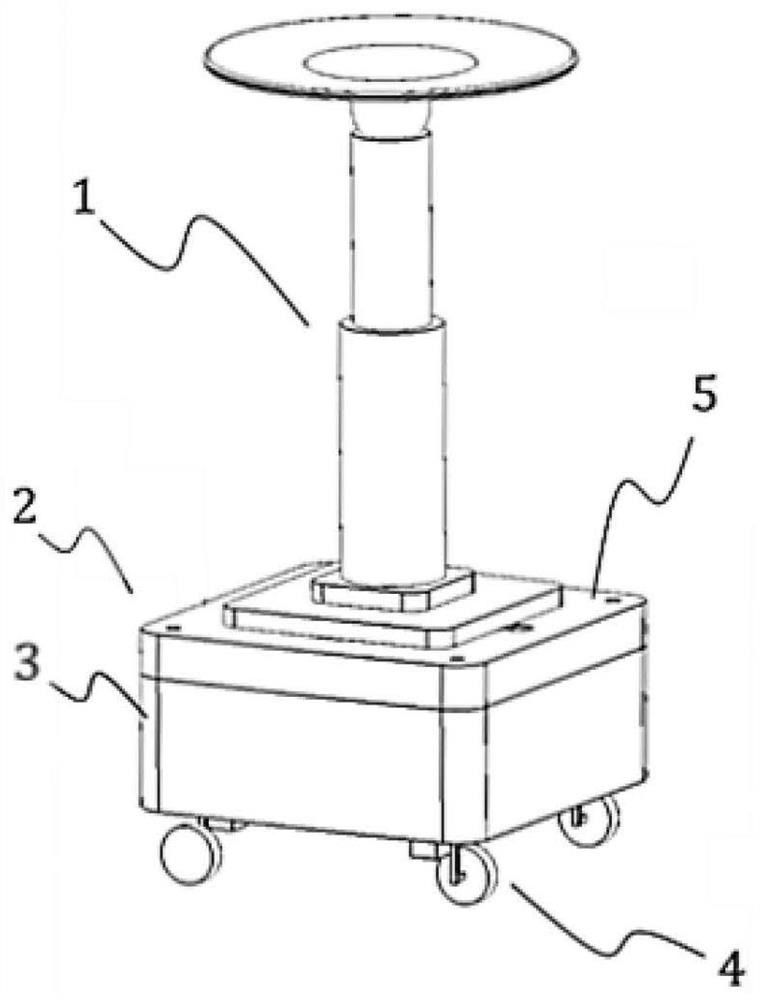

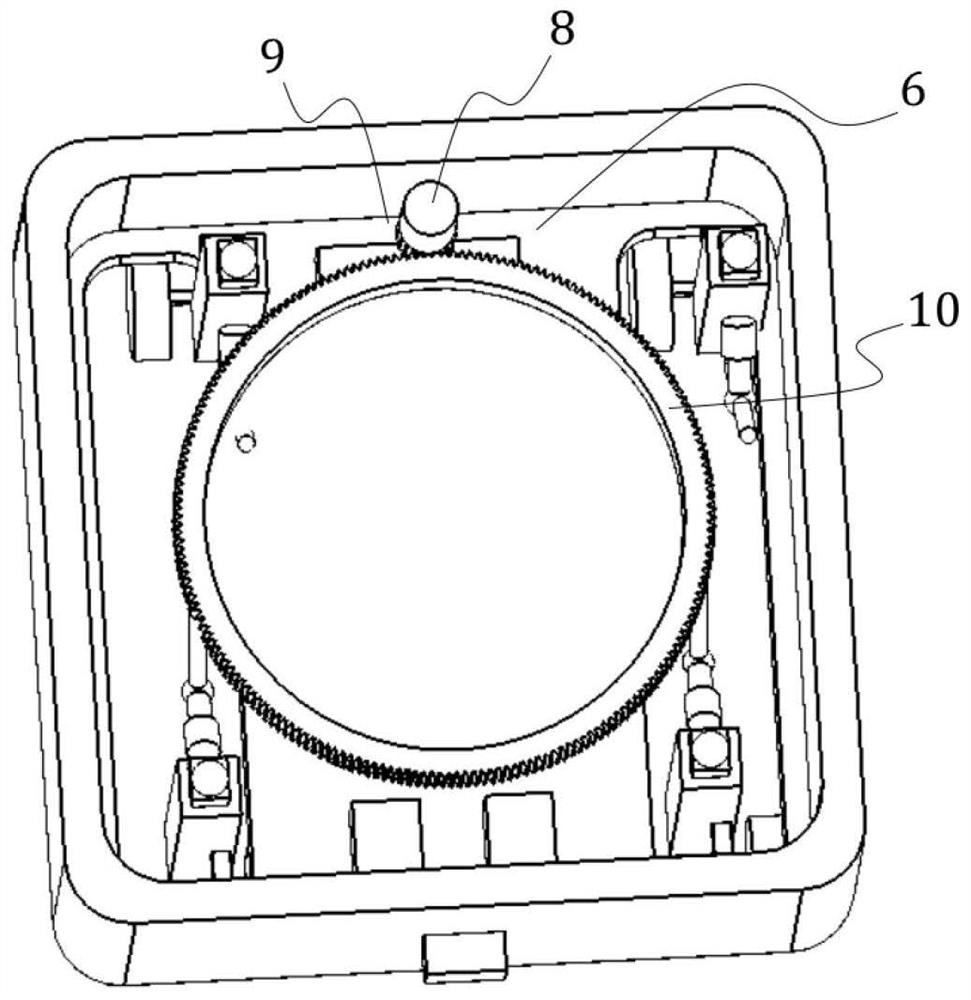

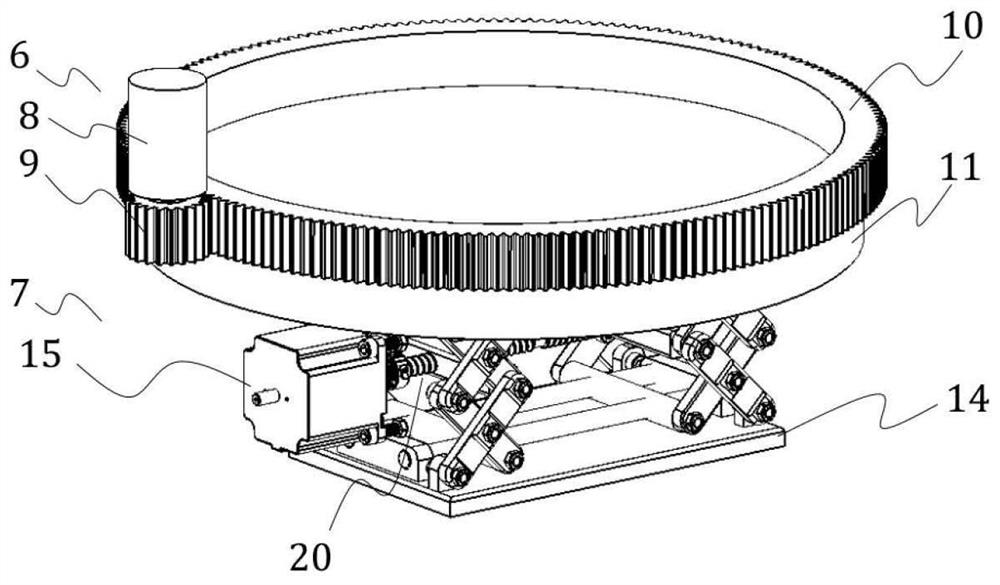

[0023] Such as figure 1 As shown, it is a wheel-type three-dimensional mobile support flexible tooling structure related to this embodiment, including: a flexible support mechanism 1 and a wheel-type mobile platform 2, wherein: the flexible support mechanism 1 is fixedly arranged on the wheel-type by supporting the installation base 5 The upper surface of the mobile platform 2.

[0024] Such as Figure 2a ~ Figure 2c As shown, the wheeled mobile platform 2 includes: a platform main body 3 and a wheel module 4, wherein: the wheel module 4 is arranged under the platform main body 3 through a telescopic support frame.

[0025] The support installation base 5 is a rectangular sheet structure, and the four corners of the support installation base 5 are symmetrically distributed with threaded holes combined with bolts to fix and connect the flexible support mechanism 1 and the platform main body 3 respectively.

[0026] The platform main body 3 is a cuboid structure, and the platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com