Front-in and front-out rotating box type horizontal split type garbage compression station

A garbage compression station, front-in front-out technology, applied in the direction of garbage transmission, garbage collection, loading/unloading, etc., can solve the problems of restricting the layout of garbage compression stations, inability to compress garbage, and reduce the efficiency of garbage compression, so as to reduce the occupied area Usable area, reasonable design, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] The directional terms mentioned in the present invention, such as: up, down, inside, outside, etc., are only for reference figure 1 direction. Accordingly, the directional terms used are for illustration only and not for limitation of the present invention.

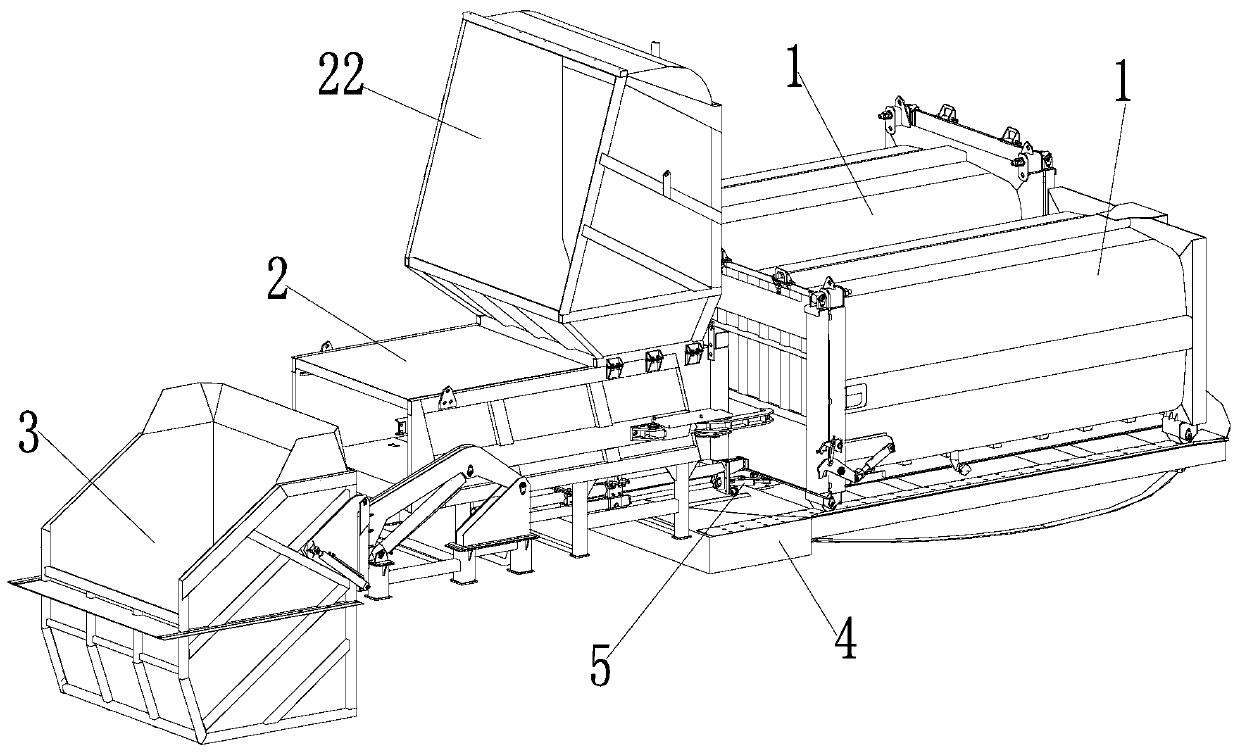

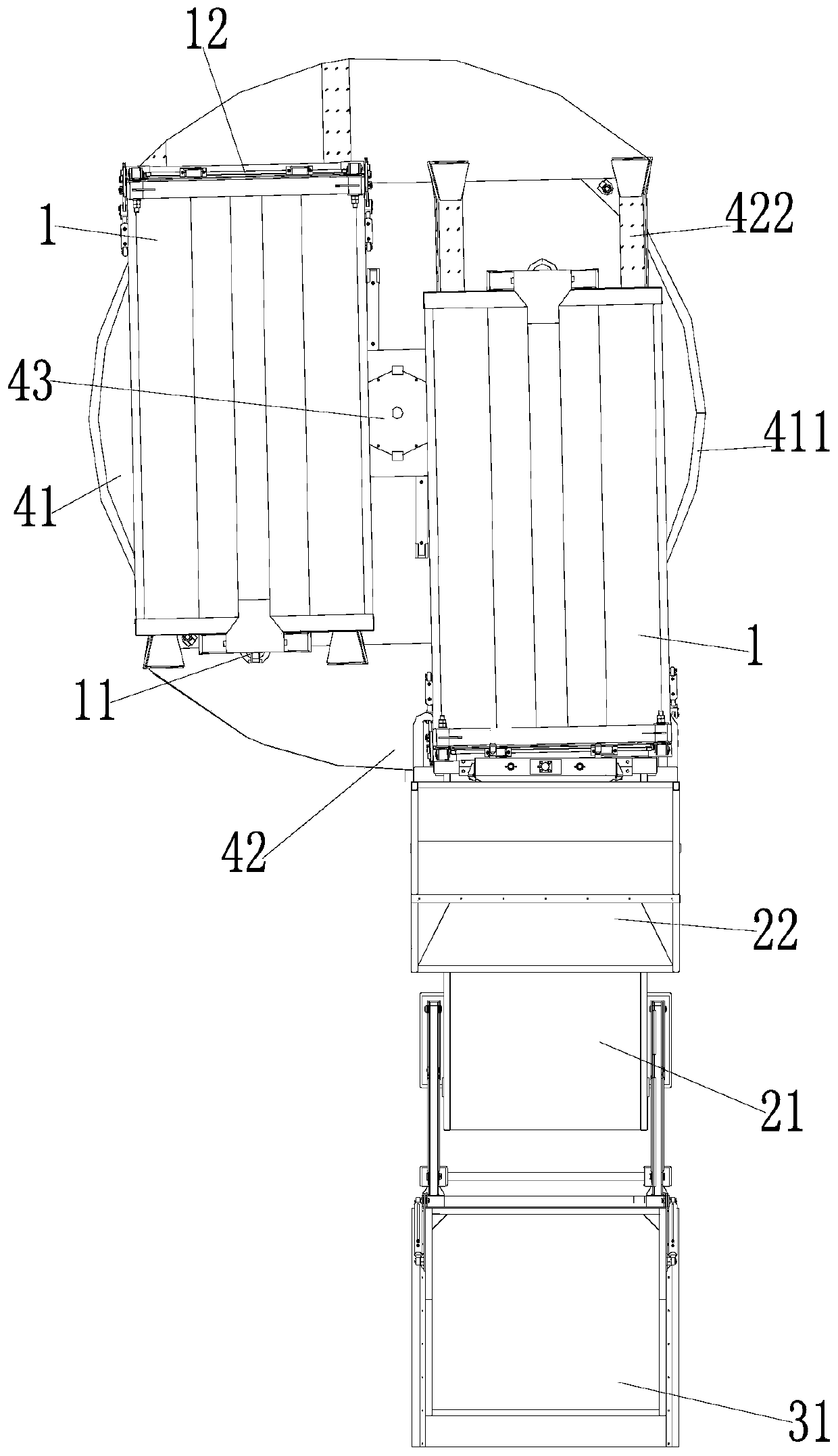

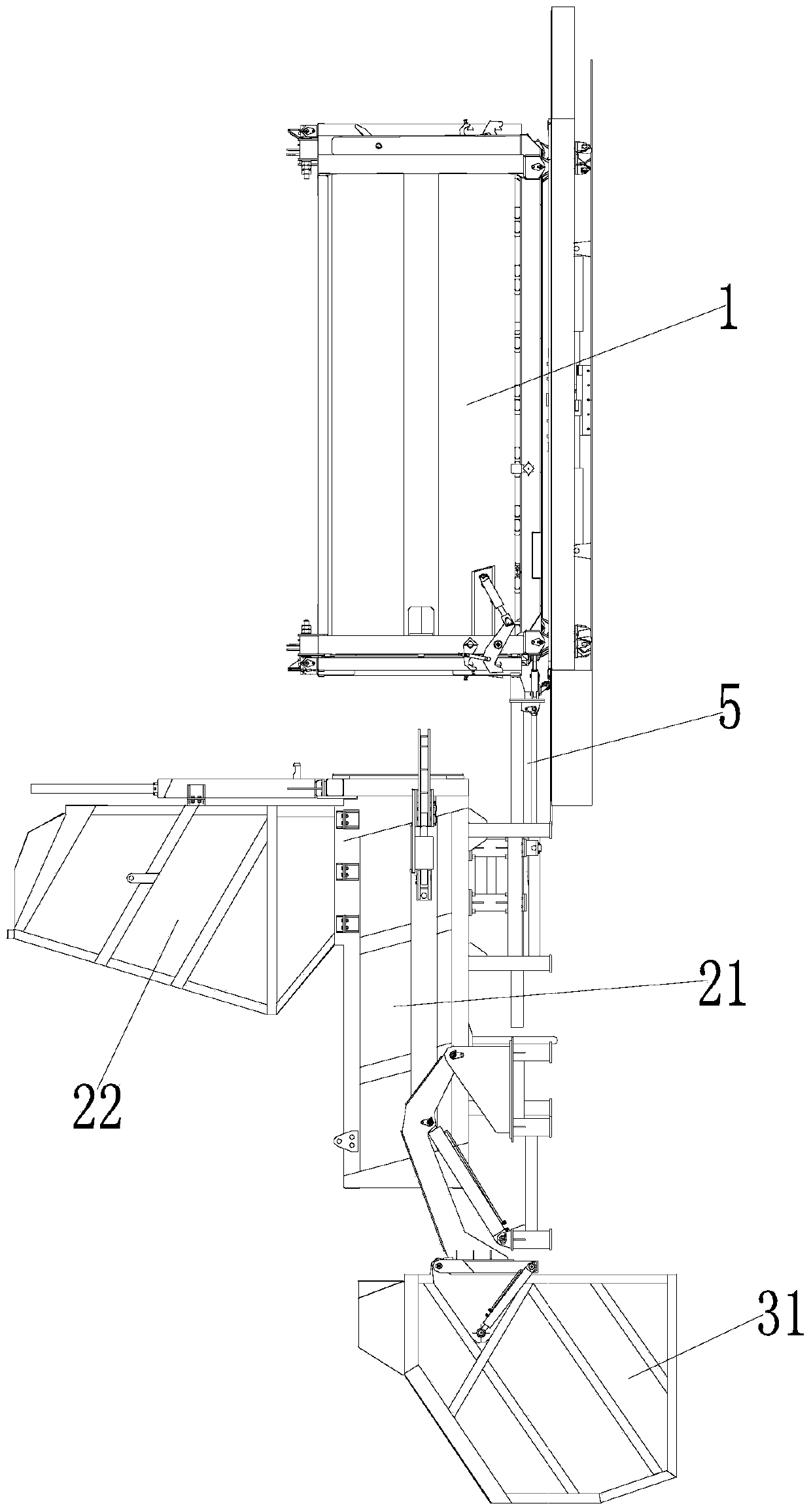

[0028] Such as Figure 1-4As shown, a forward-and-front-out transfer box type horizontally split garbage compression station includes a garbage container 1 for collecting garbage, a garbage compression device 2 for compressing garbage into the garbage container 1, and a garbage compression device 2 for putting garbage into The feeding mechanism 3 in the garbage compression device 2 also includes a turntable platform 4, and the turntable platform 4 includes a fixed base 41, a rotating platform 42, a rotating device 43, and a connecting plate 44, and the fixed base 41 is pre-embedde...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap