Novel straight beam integration module

A technology of integrated modules and straight beams, applied in the field of elevators, can solve problems such as large space occupation and complicated installation, and achieve the effects of reducing installation space, ensuring normal use, and enhancing effective protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

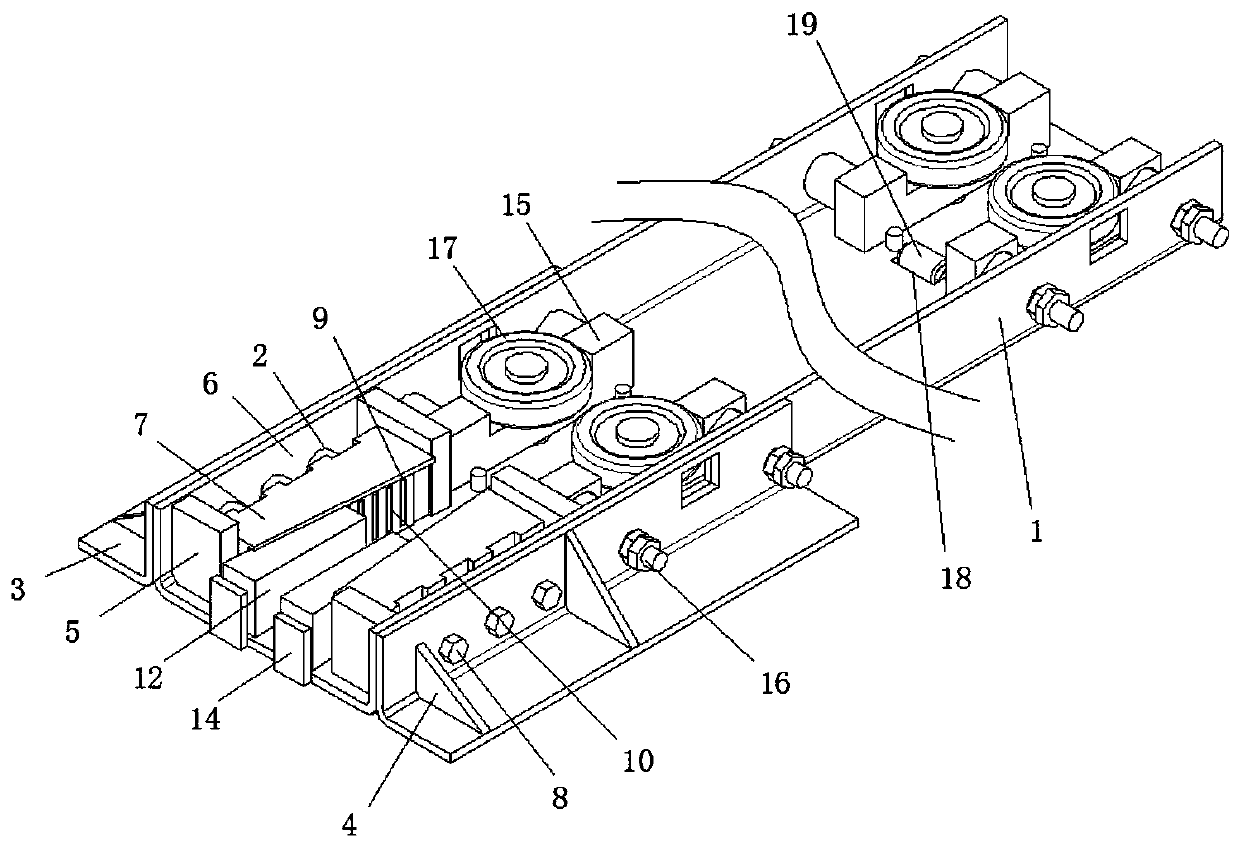

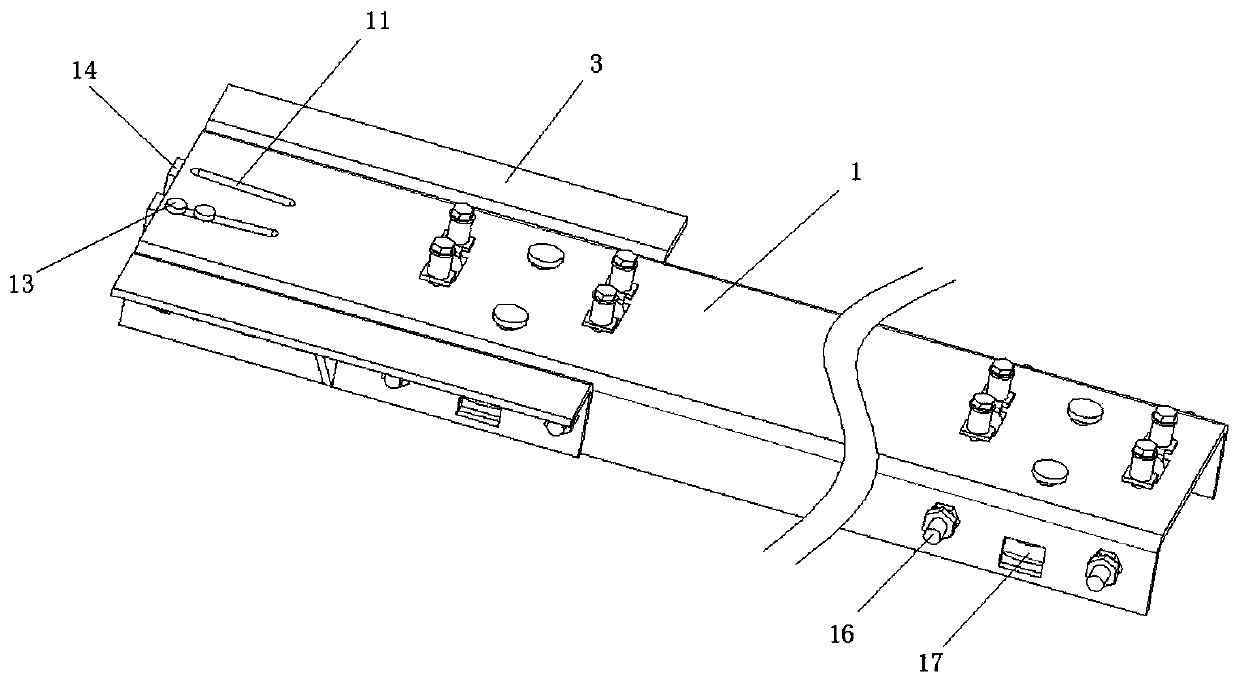

[0039] refer to Figure 1-3, a new type of straight beam integrated module, including a beam body 1, a braking mechanism and a guiding mechanism, one end of the beam body 1 is fixedly installed with a corner plate 3 on both sides of the beam body 1, and the upper surface of the corner plate 3 is fixedly installed with a reinforcement Rib 4, reinforcement plate 5 is fixedly installed on the inner wall of beam body 1, guide wedges 7 are symmetrically arranged on the braking mechanism, and guide wedges 7 are located between reinforcement plates 5;

[0040] Further, the four reinforcing plates 5 are distributed symmetrically around the axis of the beam body 1, the surface of the reinforcing plate 5 and the inner wall of the beam body 1 are provided with a safety locking cavity 6, and the inner wall of the safety locking cavity 6 is connected to the guide wedge The surface of 7 is slidingly connected, and the two guide wedges 7 are symmetrically distributed around the axis of the b...

Embodiment 2

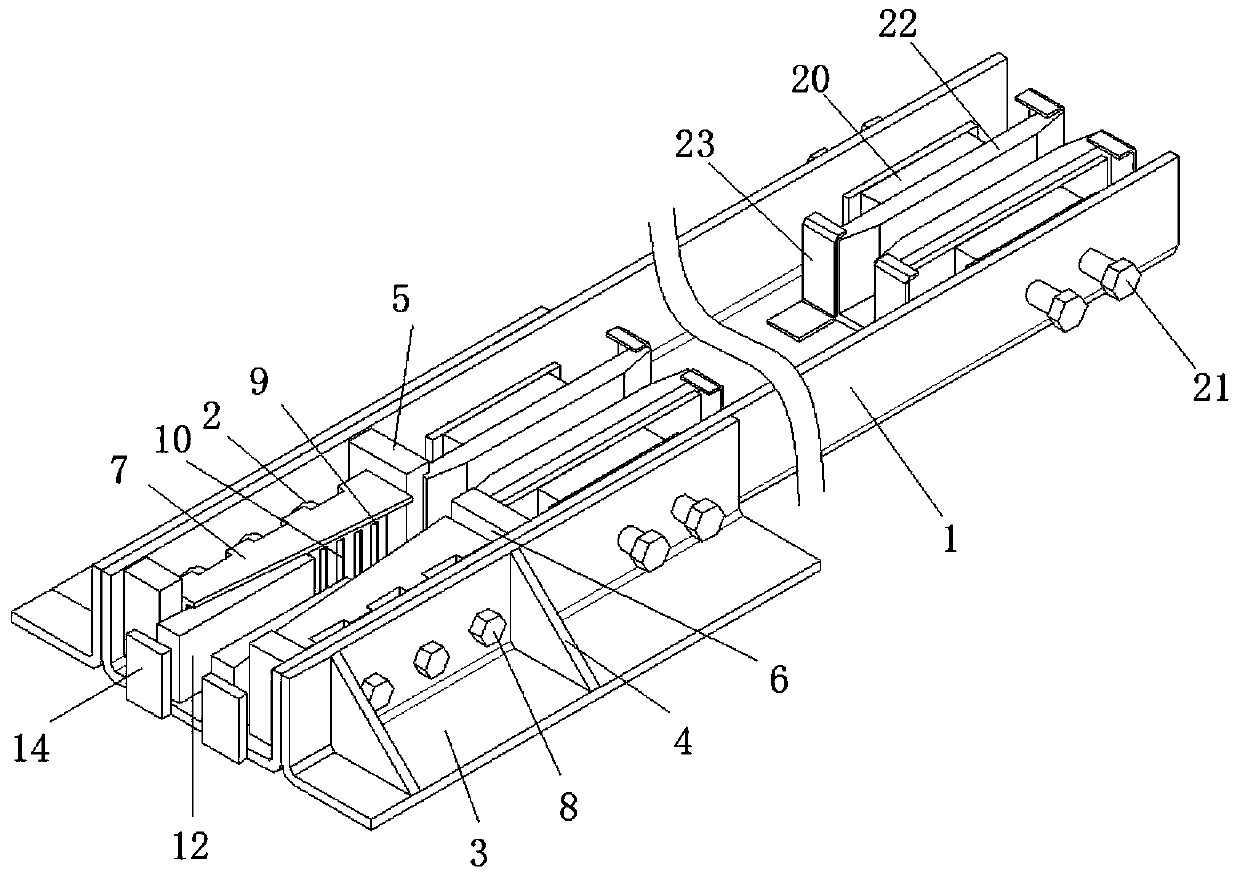

[0052] refer to Figure 1-3 , a new type of straight beam integrated module, including a beam body 1, a braking mechanism and a guiding mechanism, one end of the beam body 1 is fixedly installed with a corner plate 3 on both sides of the beam body 1, and the upper surface of the corner plate 3 is fixedly installed with a reinforcement Rib 4, reinforcement plate 5 is fixedly installed on the inner wall of beam body 1, guide wedges 7 are symmetrically arranged on the braking mechanism, and guide wedges 7 are located between reinforcement plates 5;

[0053] Further, the four reinforcing plates 5 are distributed symmetrically around the axis of the beam body 1, the surface of the reinforcing plate 5 and the inner wall of the beam body 1 are provided with a safety locking cavity 6, and the inner wall of the safety locking cavity 6 is connected to the guide wedge The surface of 7 is slidingly connected, and the two guide wedges 7 are symmetrically distributed around the axis of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com