Patents

Literature

35results about How to "Ensure lifting safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

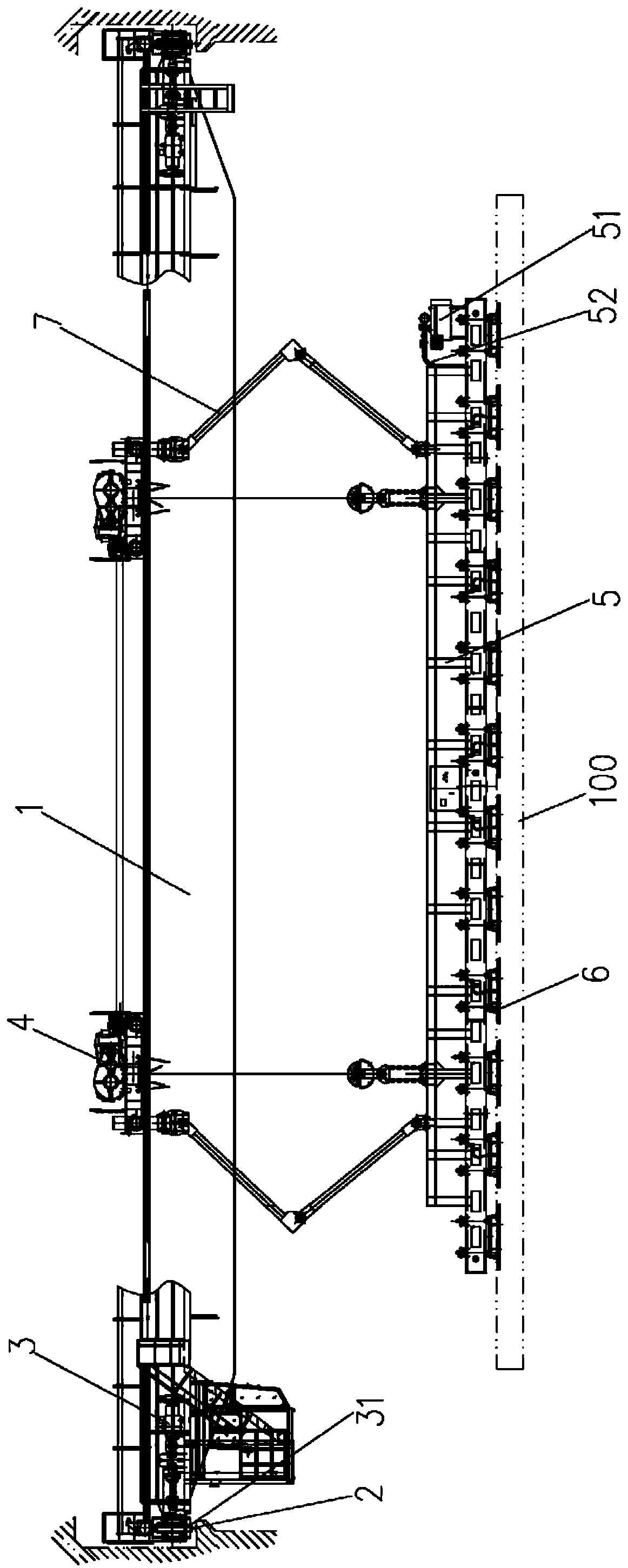

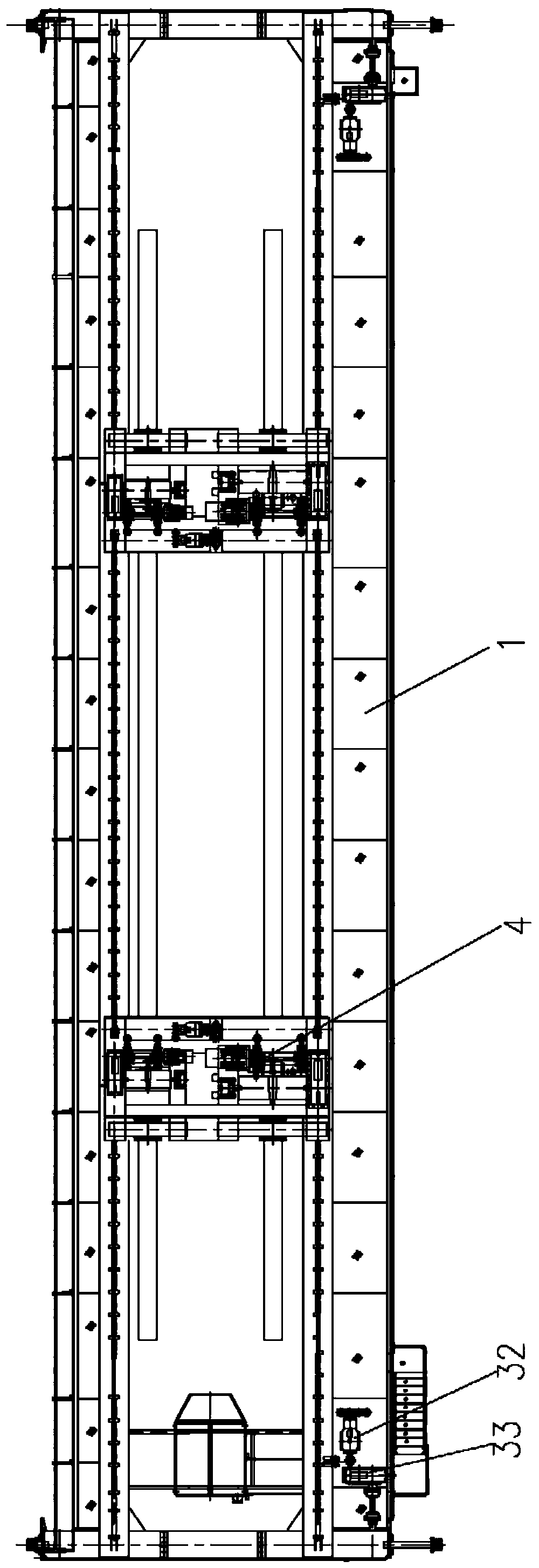

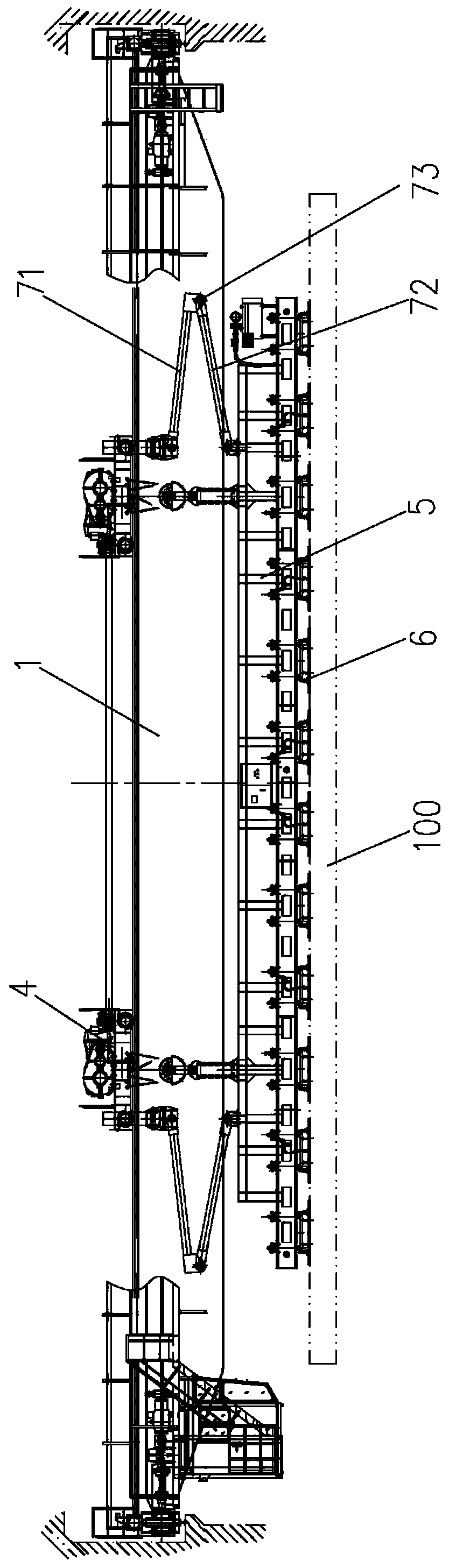

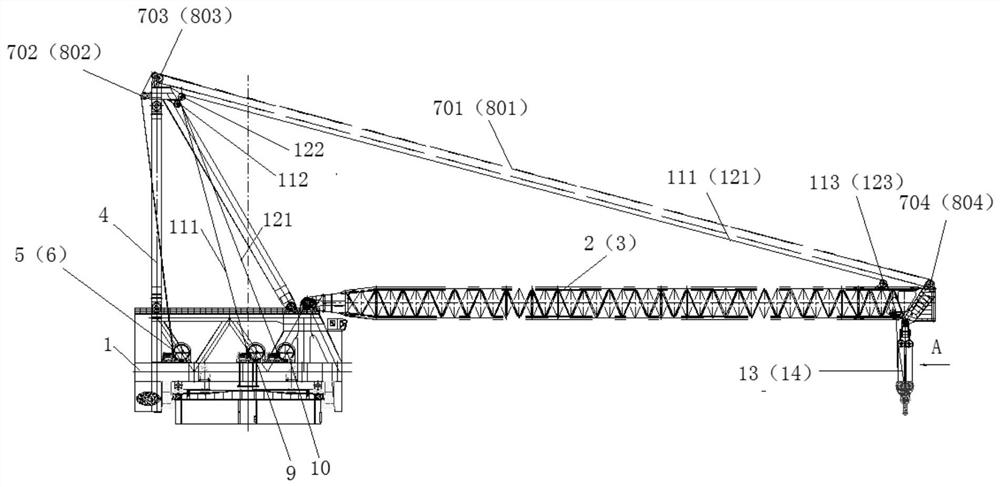

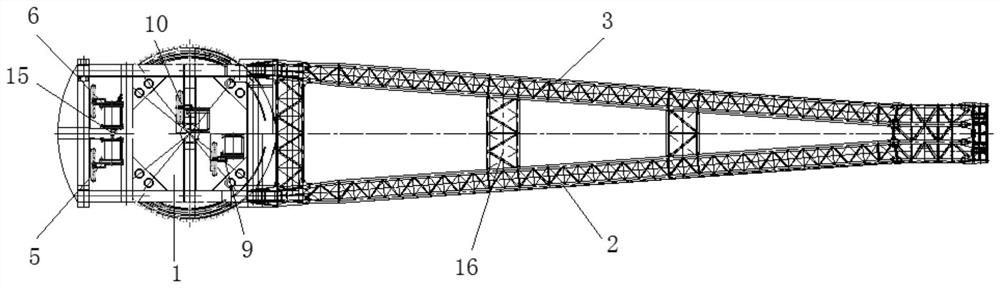

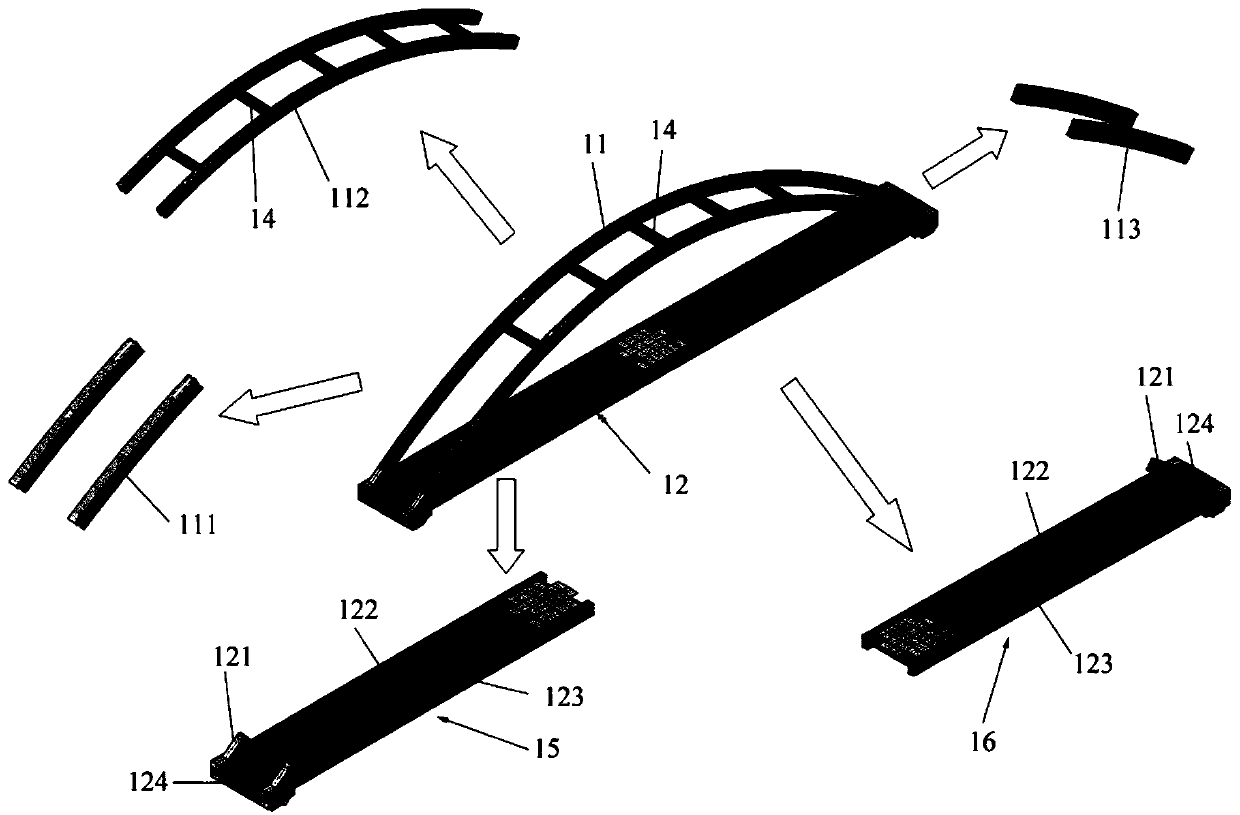

Construction method of large-span through type rigid tied bar steel arch bridge

InactiveCN107905116AEnsure safetyAutomatic length adjustmentBridge erection/assemblyMain channelSubstructure

The invention discloses a construction method of a large-span through type rigid tied bar steel arch bridge. The steel arch bridge comprises a bridge superstructure, a bridge substructure and a bridgebearing. The construction method comprises the following steps that construction of the bridge substructure is conducted; sectional prefabrication of the bridge superstructure is conducted; integralassembling of the bridge superstructure is conducted; the bridge superstructure is overall hoisted through a floating crane; tugboats abreast tow the floating crane to sail in a main channel; the floating crane is subjected to load movement in a narrow river channel; and the bridge superstructure is overall mounted through position adjusting. According to the construction method, segmented-transporting of the bridge superstructure to a bridge site for overall assembling is not required, overall assembling of the overall assembling is completed in an overall assembling site of a wharf, and thenone floating crane is adopted to overall hoist the bridge superstructure to the bridge site for overall hoisting; and the scheme does not require building of a temporary support, the requirement of conditions of a construction site is low, impact on the surrounding environment is low, and the construction period is short.

Owner:CHINA SINOCONST HEAVY IND +1

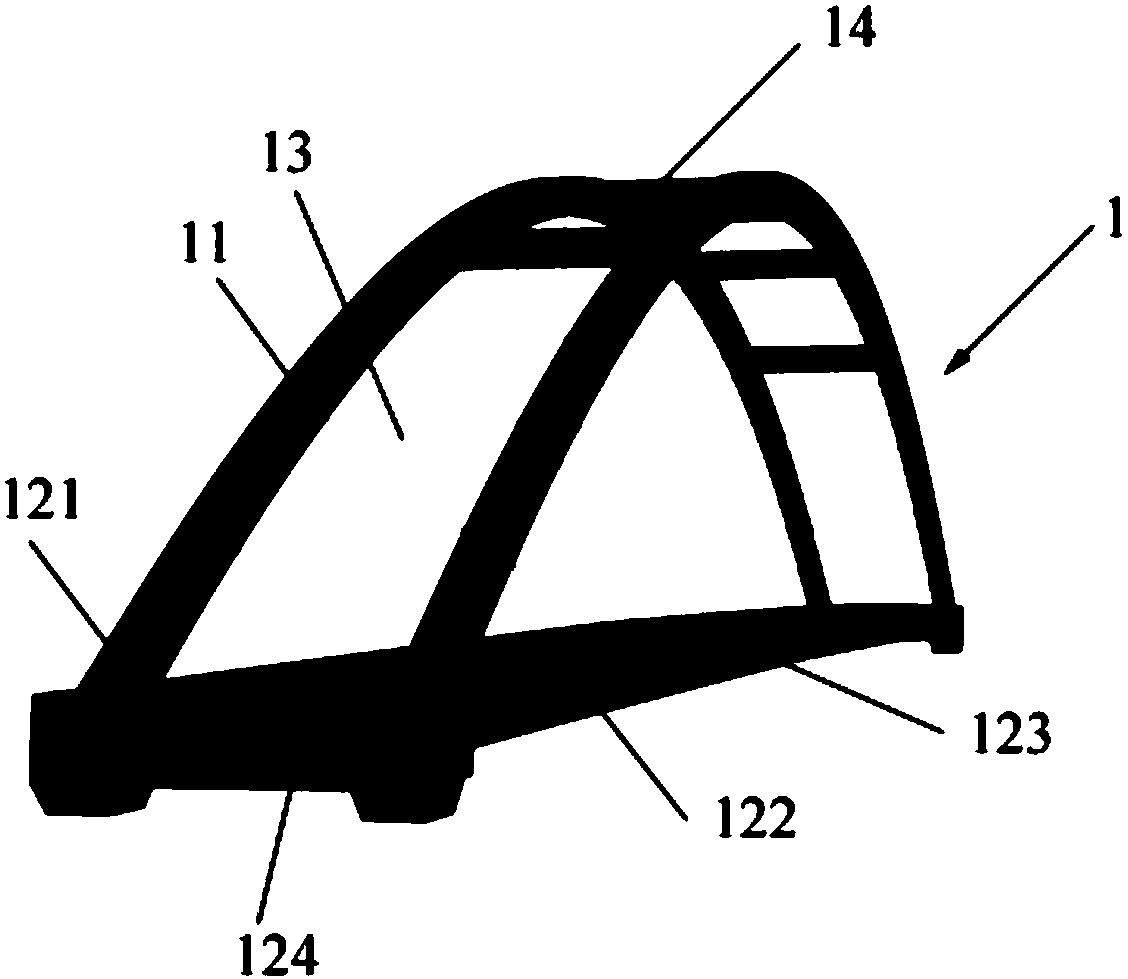

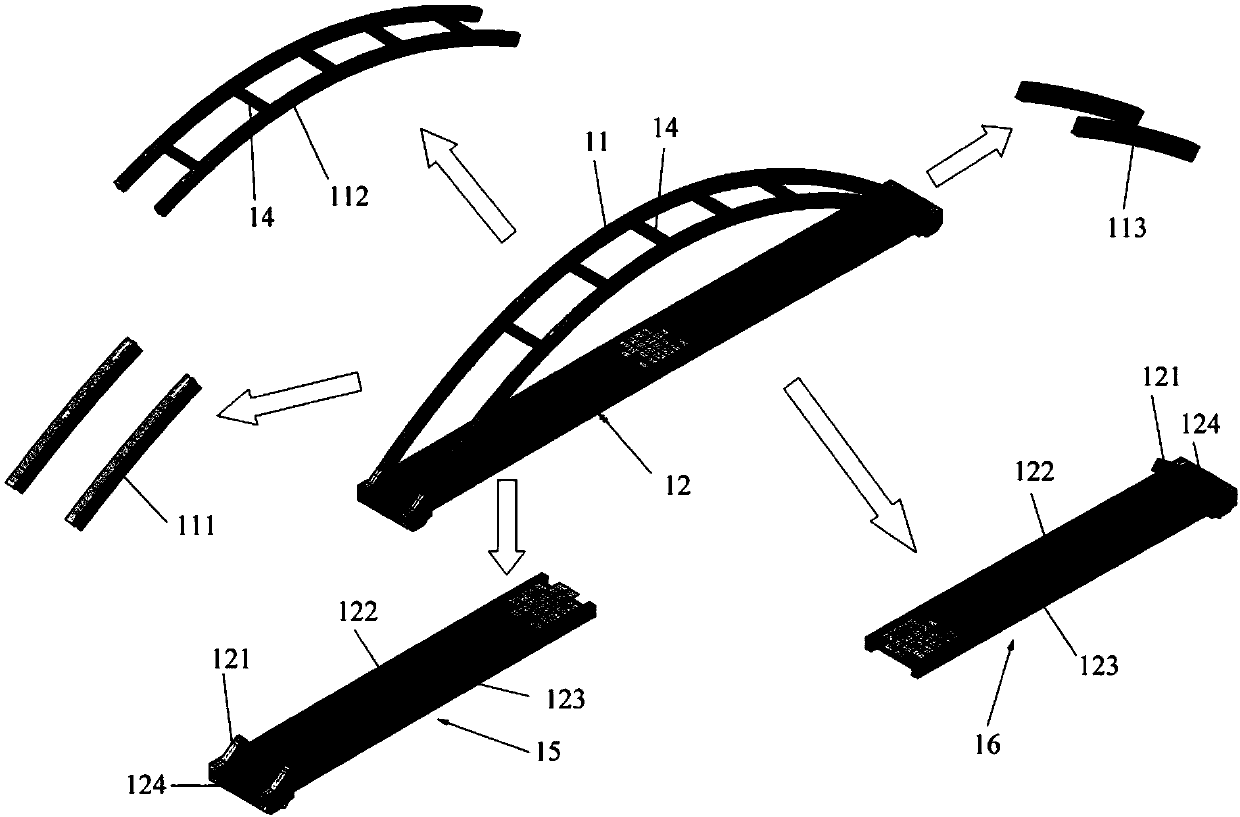

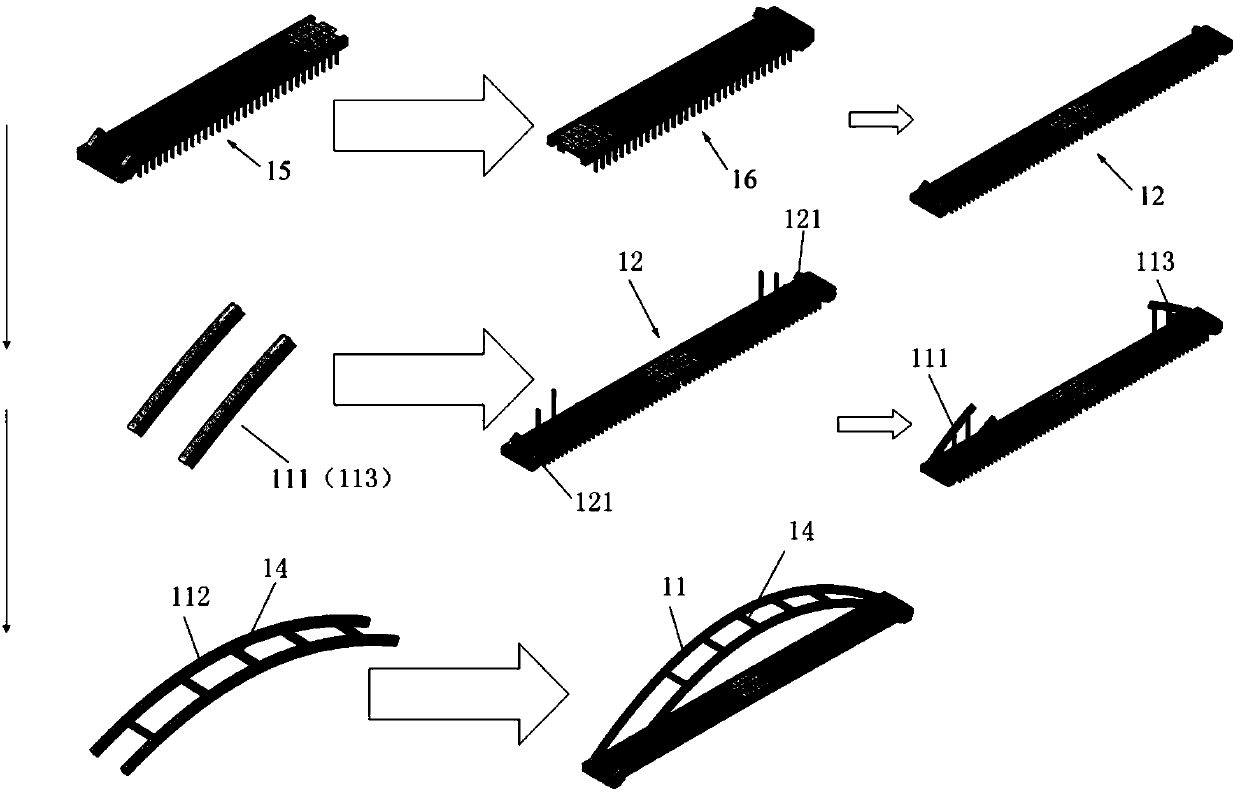

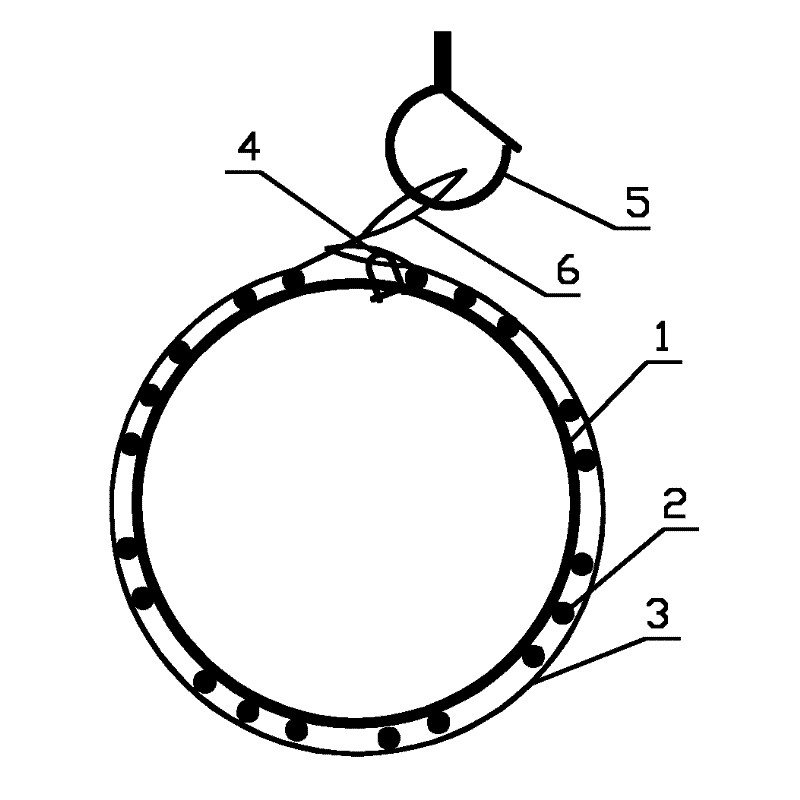

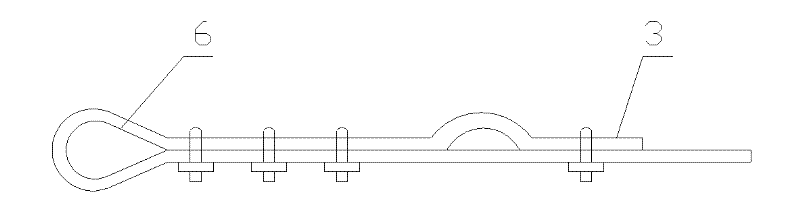

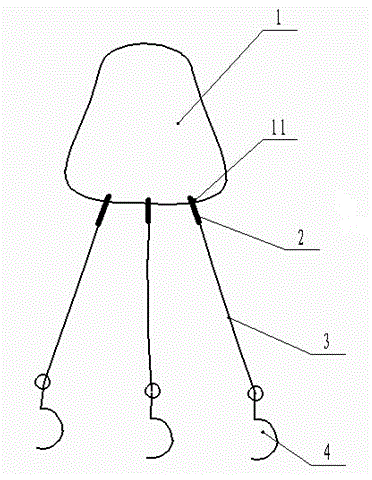

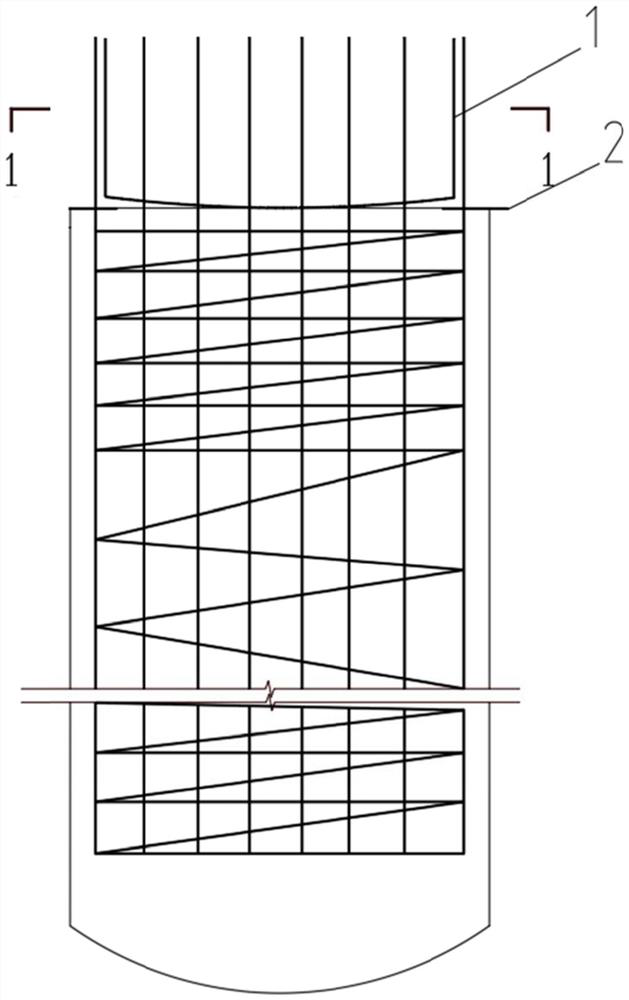

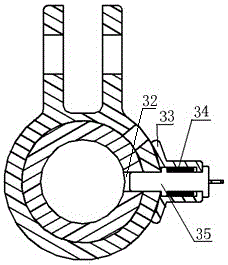

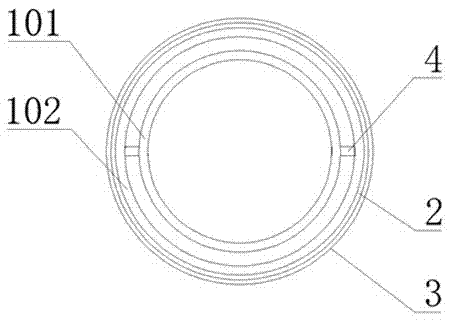

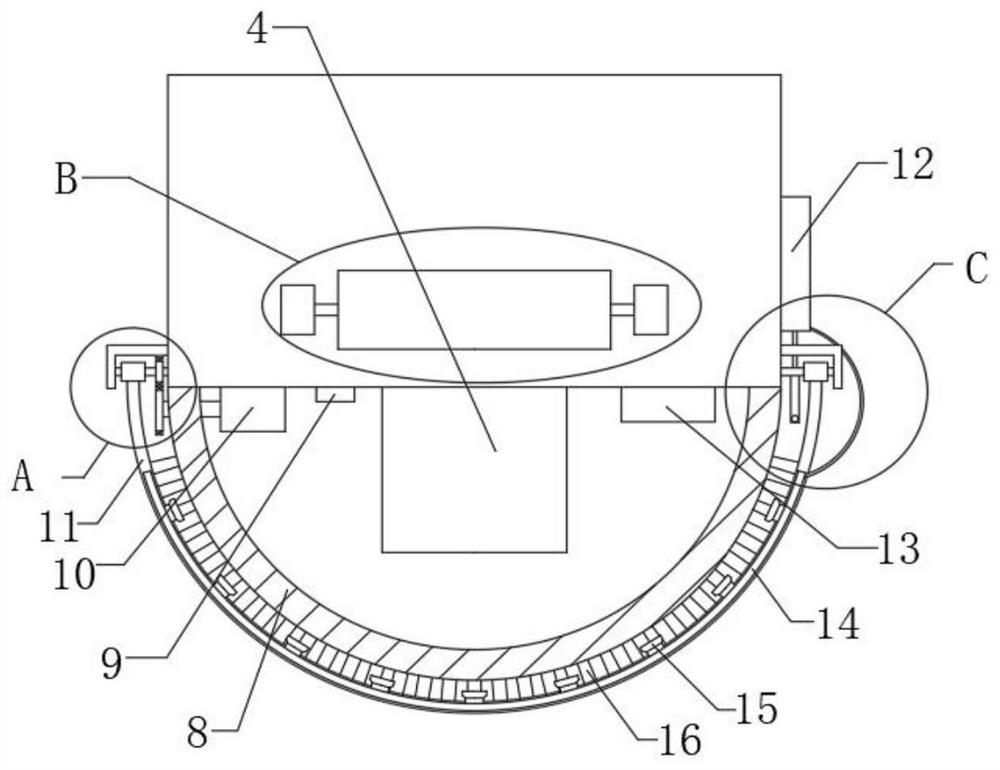

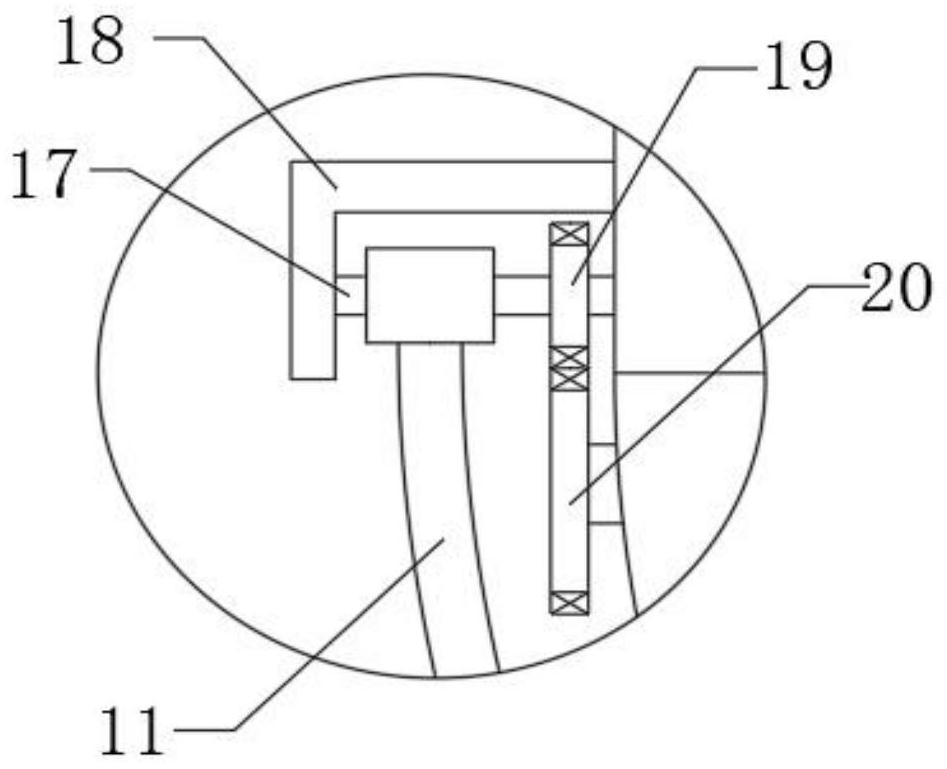

A steel cage lifting structure

InactiveCN102295225AAvoid accidents when the reinforcement hoop is disengagedPrevent vertical slidingLoad-engaging elementsEngineeringRebar

The invention discloses a reinforcement cage lifting structure, which is welded to the inner ring of the main reinforcement ring of the reinforcement cage, and three steel wire ropes are respectively sleeved on the outside of the reinforcement cage at the lifting point A, the lifting point B and the lifting point C to tighten the reinforcement cage. Both ends of the steel wire rope are provided with collars, one of which passes through the other end collar and hangs on the hook, and the other end collar is locked together with the reinforcing hoop through a shackle. The present invention will be welded on the inner ring of the main reinforcement ring of the reinforcement cage. In this way, when lifting, the steel wire rope is tightened, and its inward side pressure is borne by the reinforcement hoop, and the main reinforcement is not stressed, so that the welding quality of the reinforcement hoop and the main reinforcement can be avoided. Accidents where the main reinforcement is detached from the reinforcement hoop due to poor performance.

Owner:ZHONGTIAN CONSTR GROUP +1

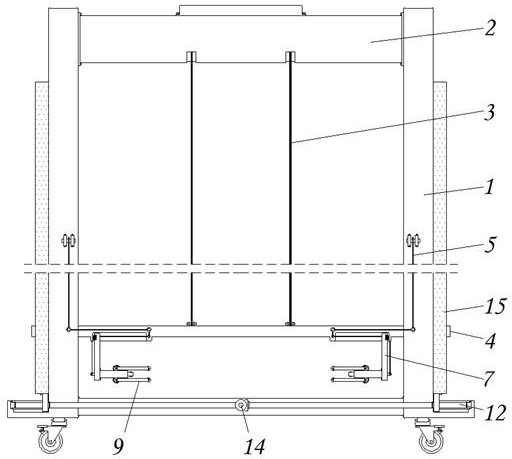

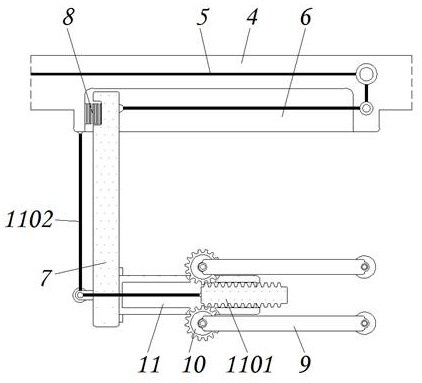

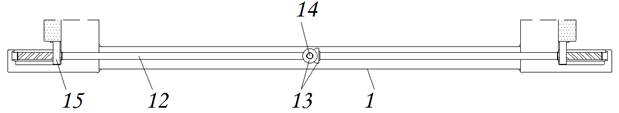

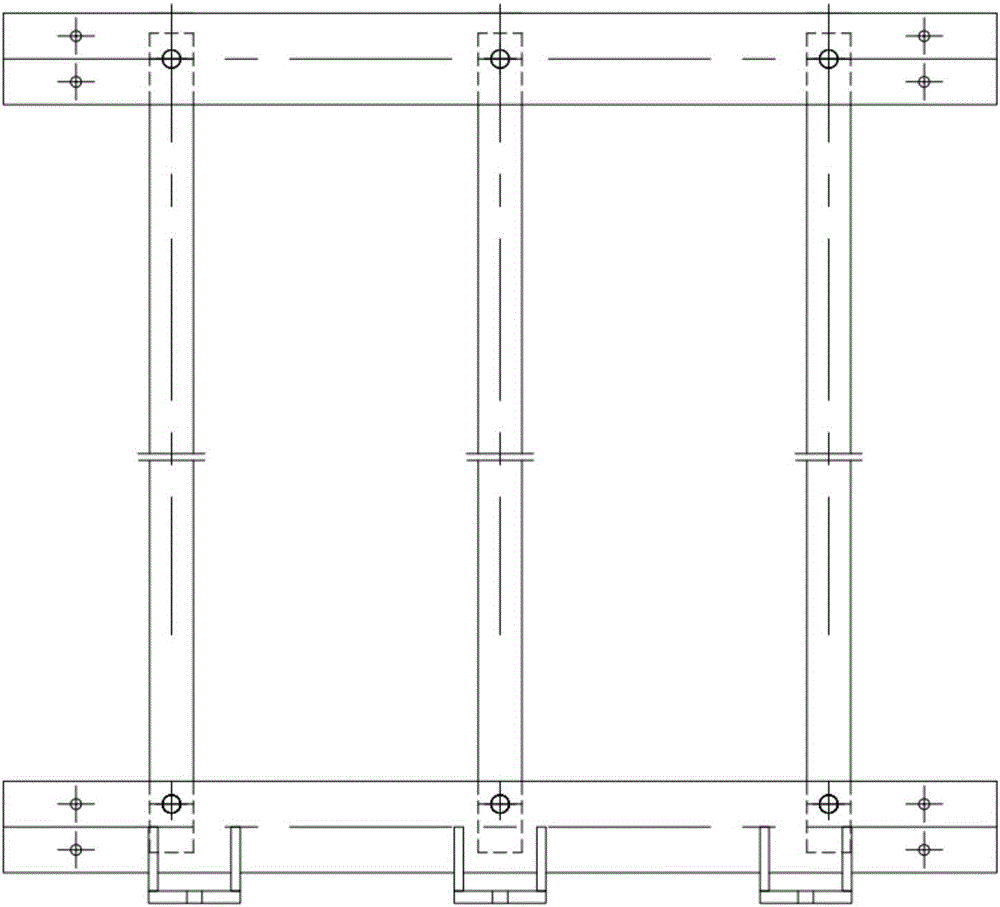

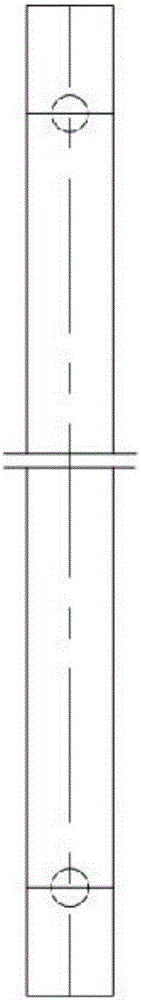

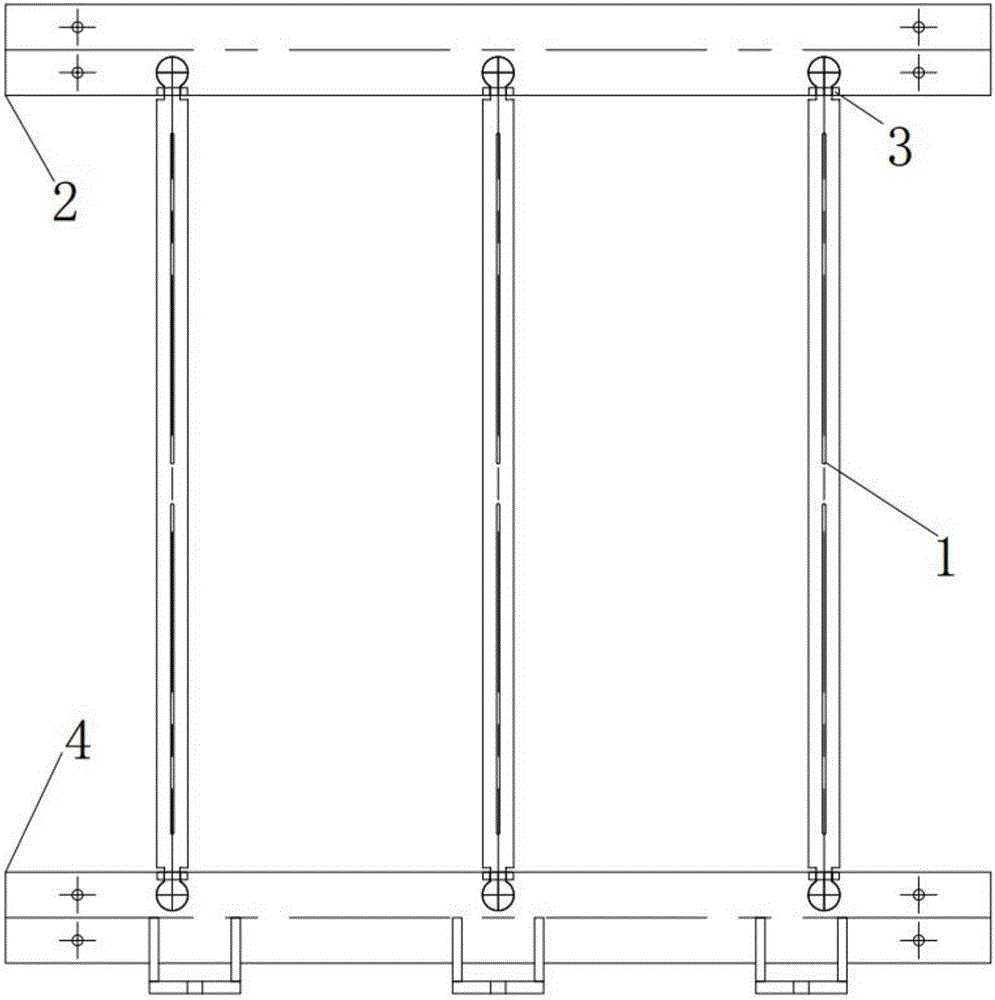

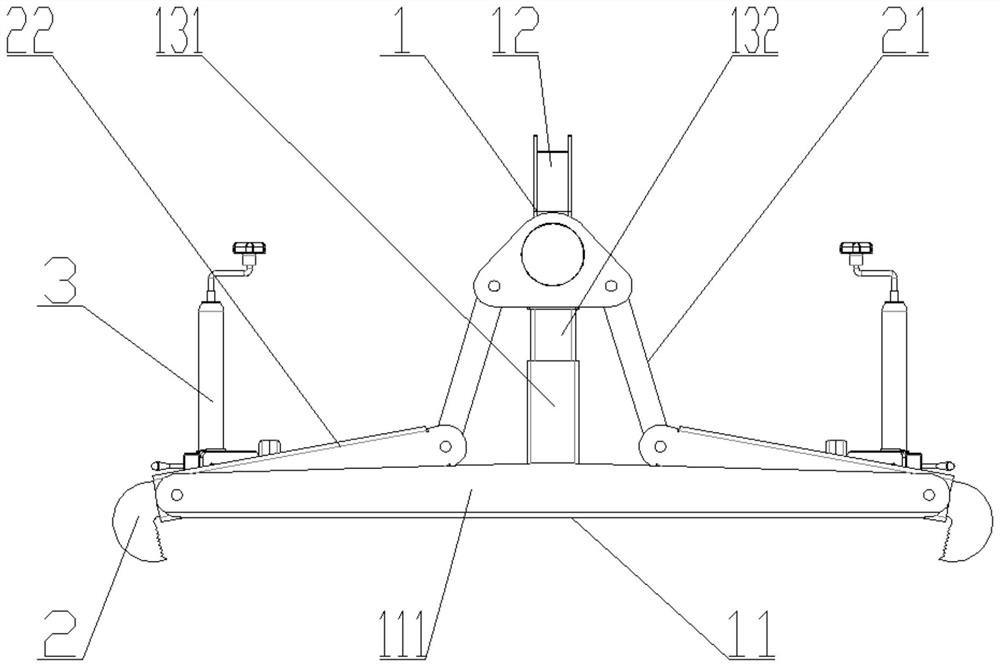

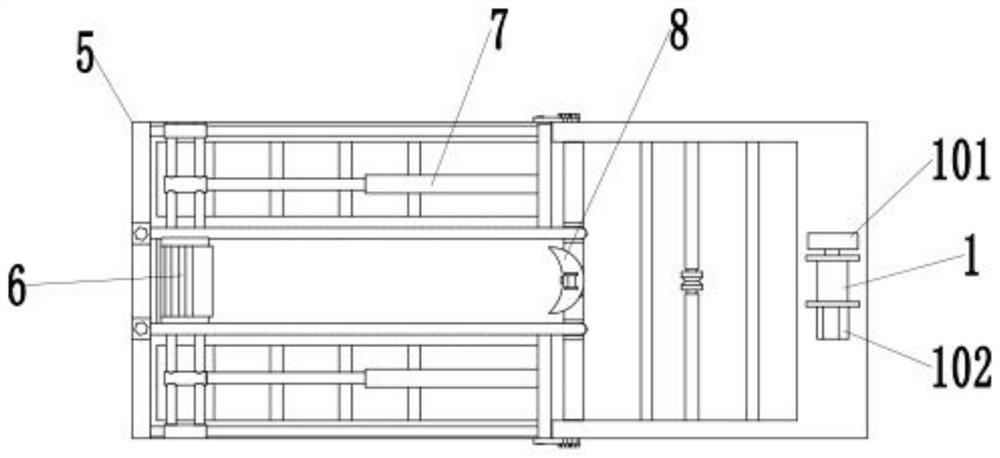

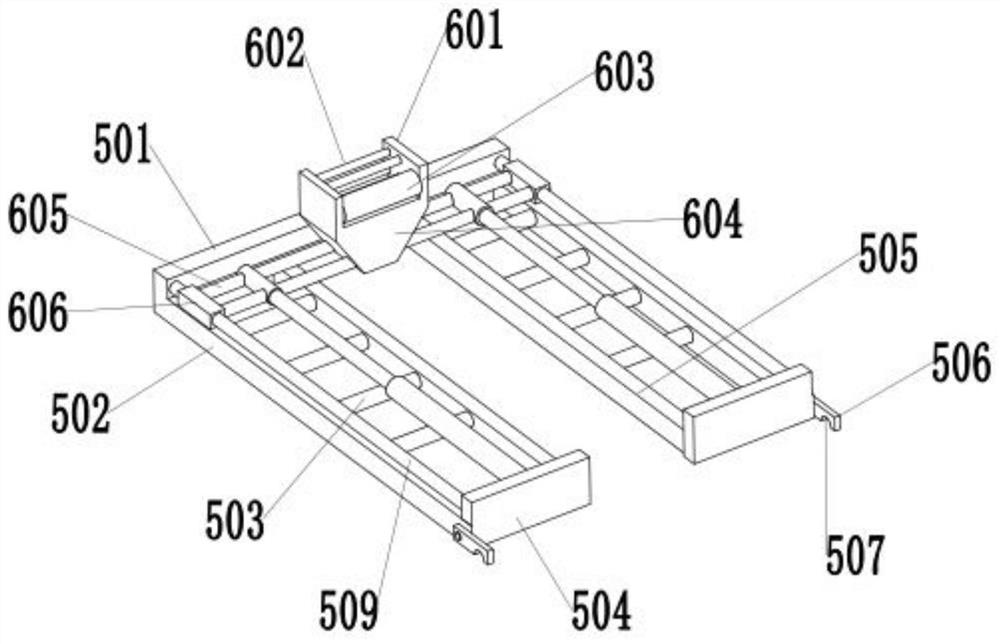

Square pile vacuum suction disk bridge type crane

PendingCN110510493AAvoid shakingLifting safetyNon-rotating vibration suppressionTrolley cranesBridge typeOverhead crane

The invention relates to a square pile vacuum suction disk bridge type crane which is used for hoisting and transporting square piles. The square pile vacuum suction disk bridge type crane comprises abridge frame, steel rails, bridge frame running mechanisms, a lifting trolley, a hoisting beam, suction disk devices and an anti-waggling device, wherein the bridge frame is supported on the steel rails; the bridge frame running mechanisms are arranged at the two ends of the bridge frame, and can be used for driving the bridge frame to travel along the steel rails; the lifting trolley is installed on the bridge frame, is connected with the hoisting beam and can be used for driving the hoisting beam to lift; the suction disk devices are installed at the bottom of the hoisting beam at equal intervals, and can be used for adsorbing the square piles; and the anti-waggling device is connected between the lifting trolley and the hoisting beam. The square pile vacuum suction disk bridge type crane has the advantages of being high in hoisting efficiency, safe and reliable in use, and the like, and is especially suitable for square pile hoisting and transporting.

Owner:SHAOXING CRANE GENERAL FACTORY

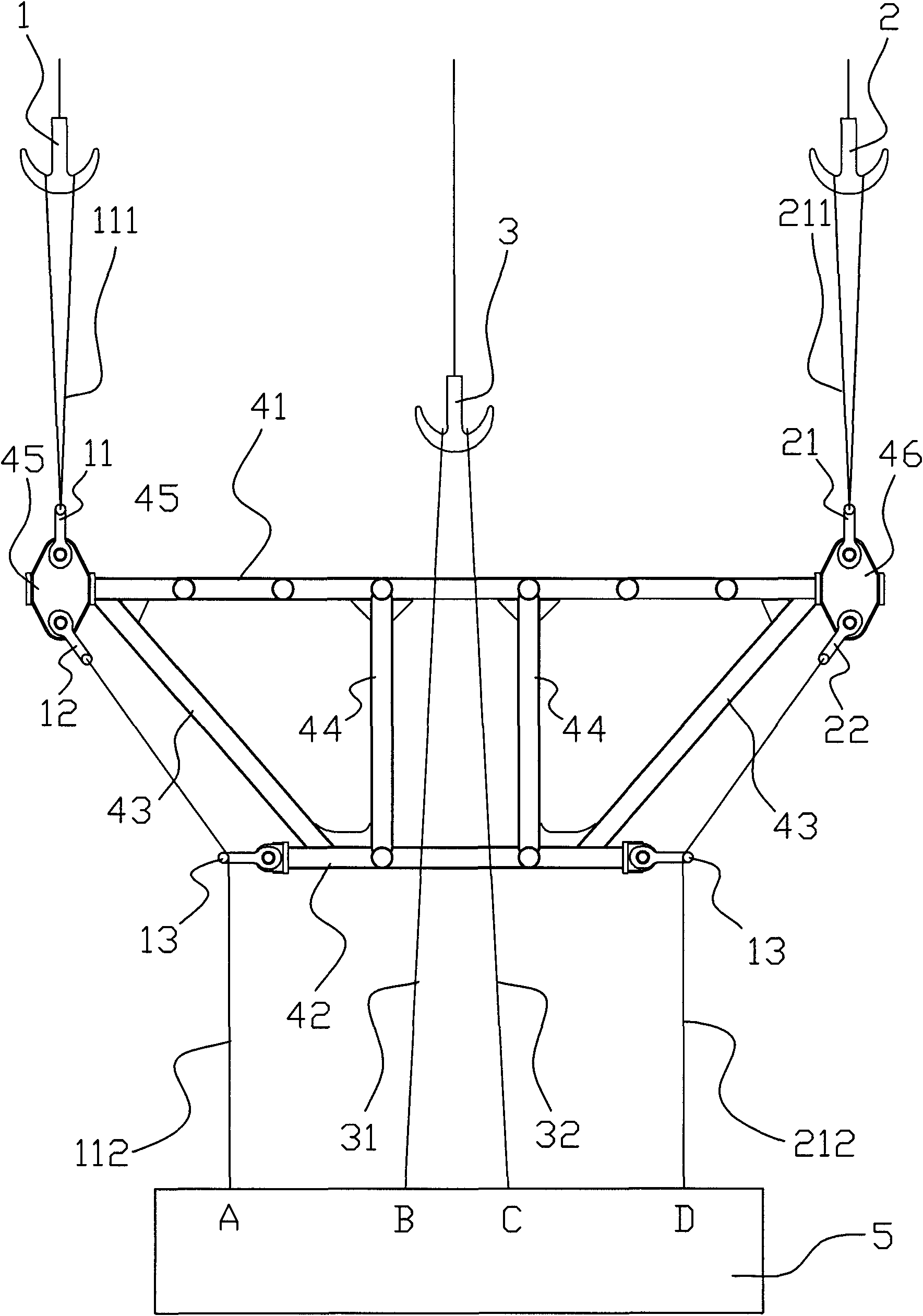

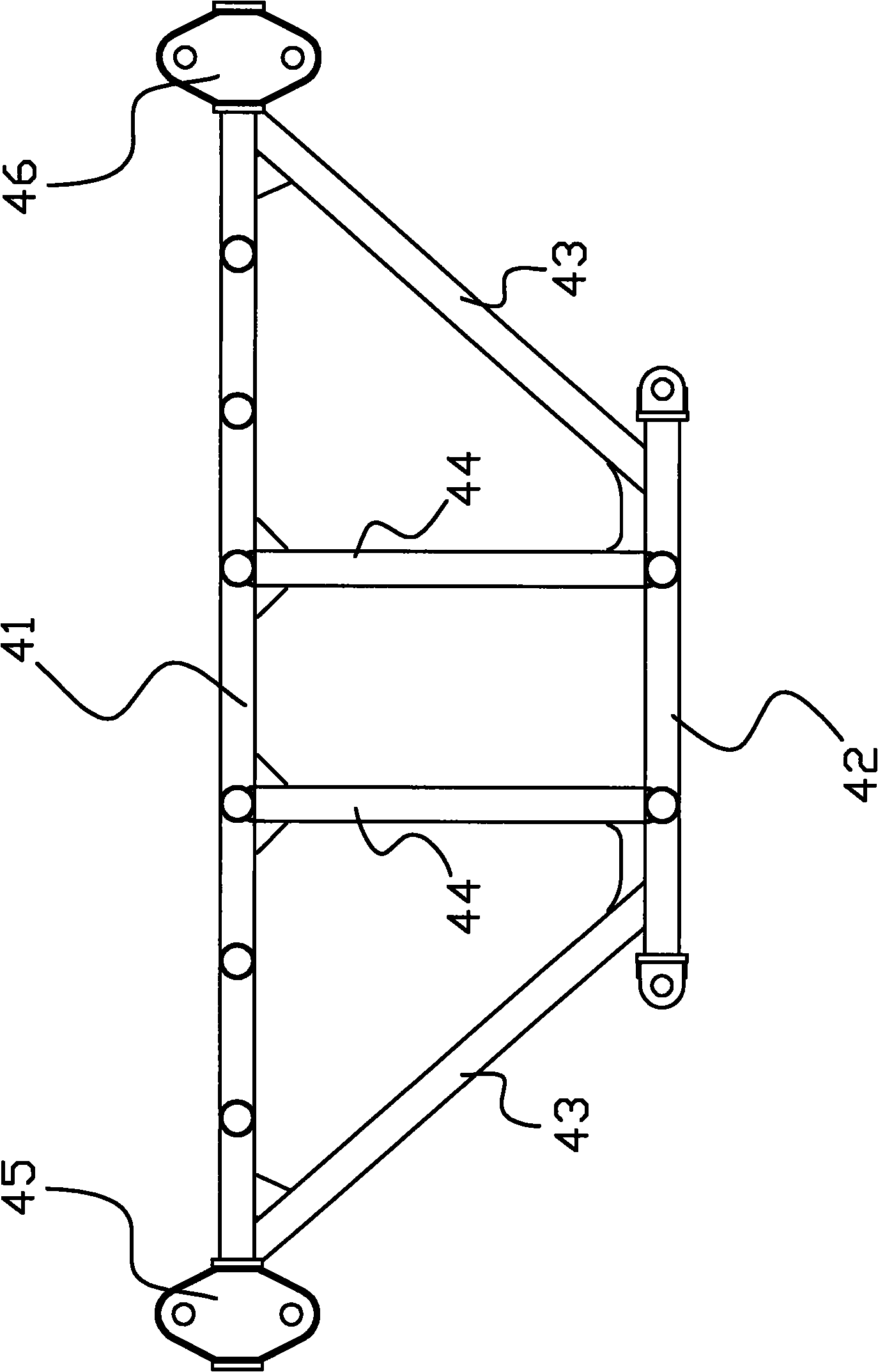

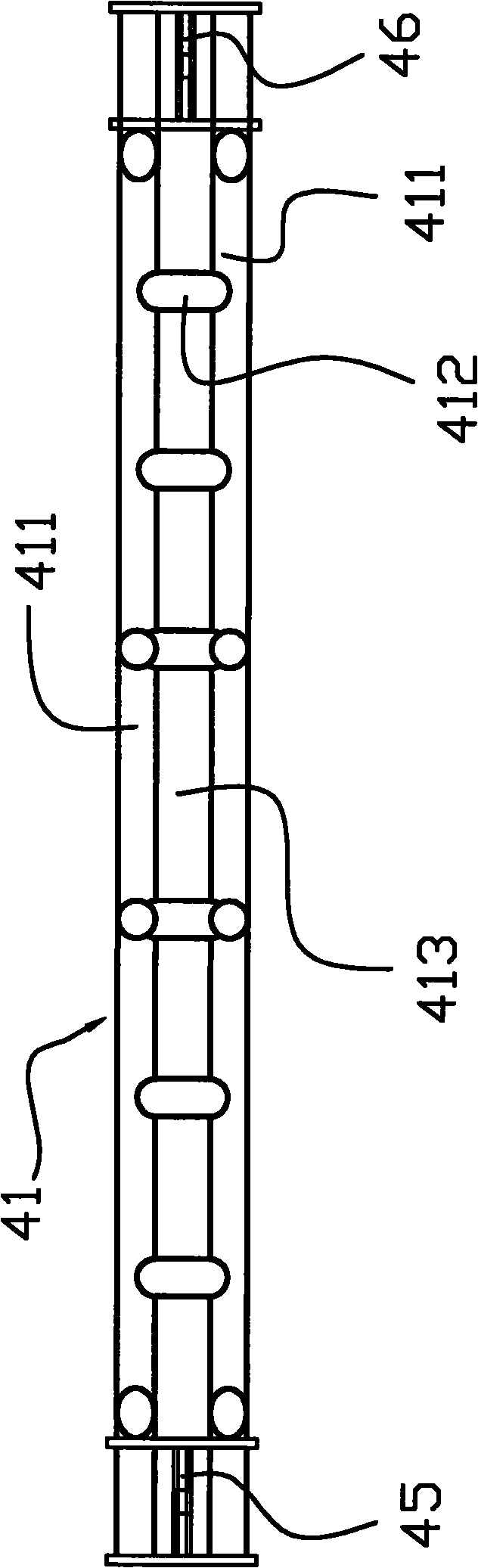

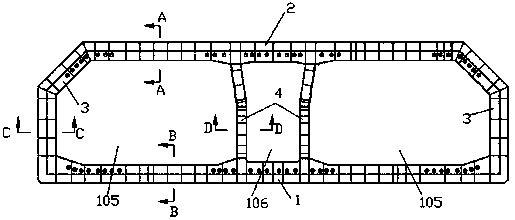

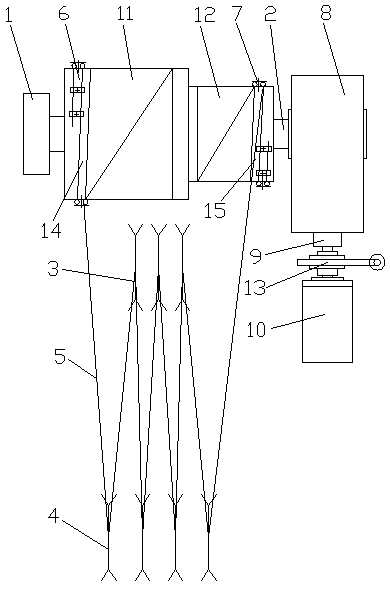

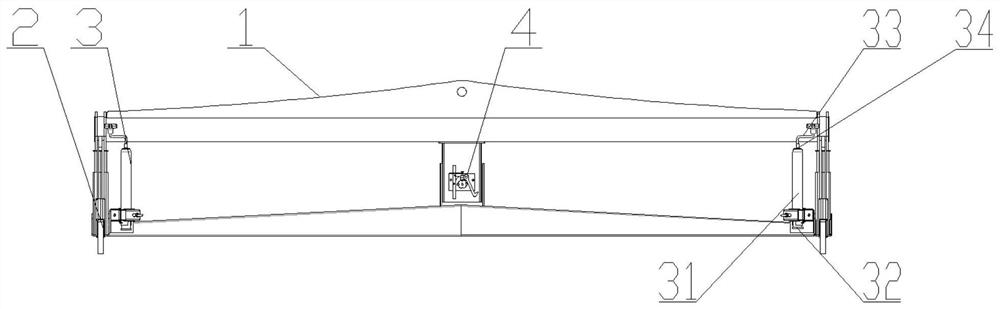

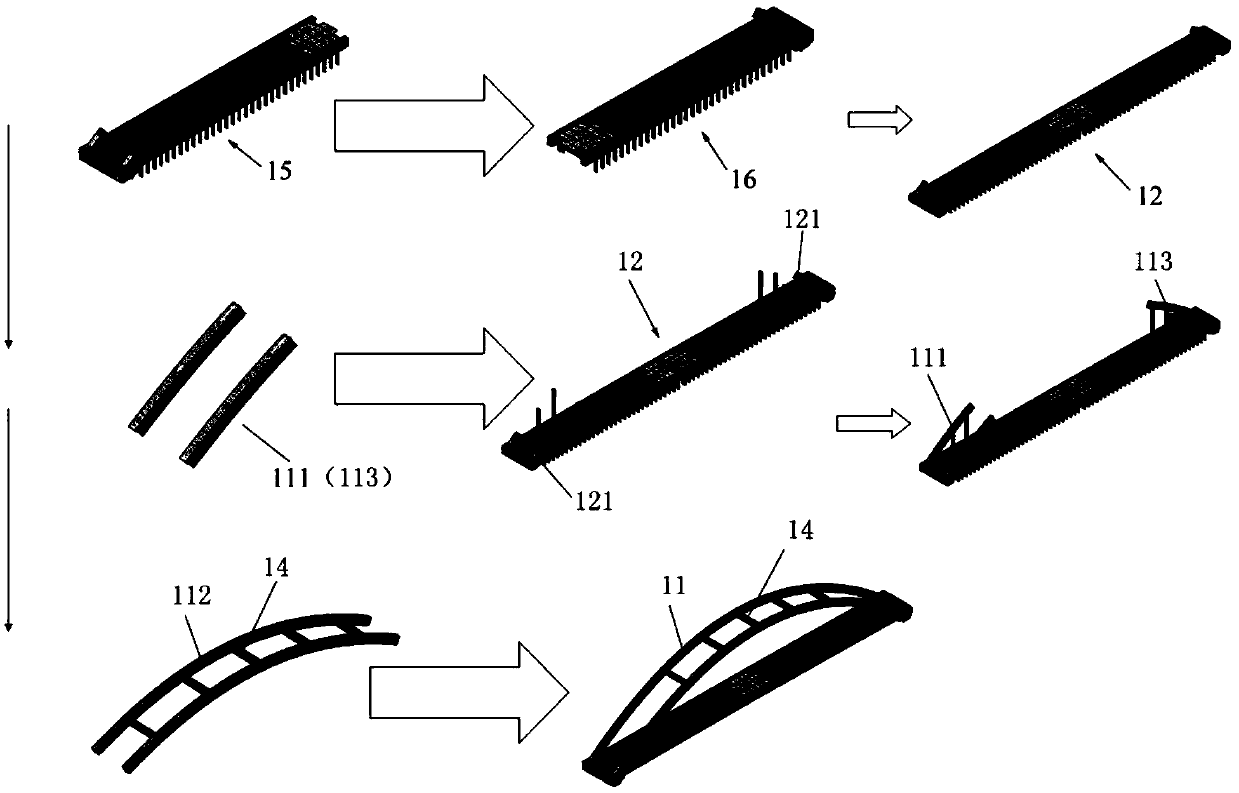

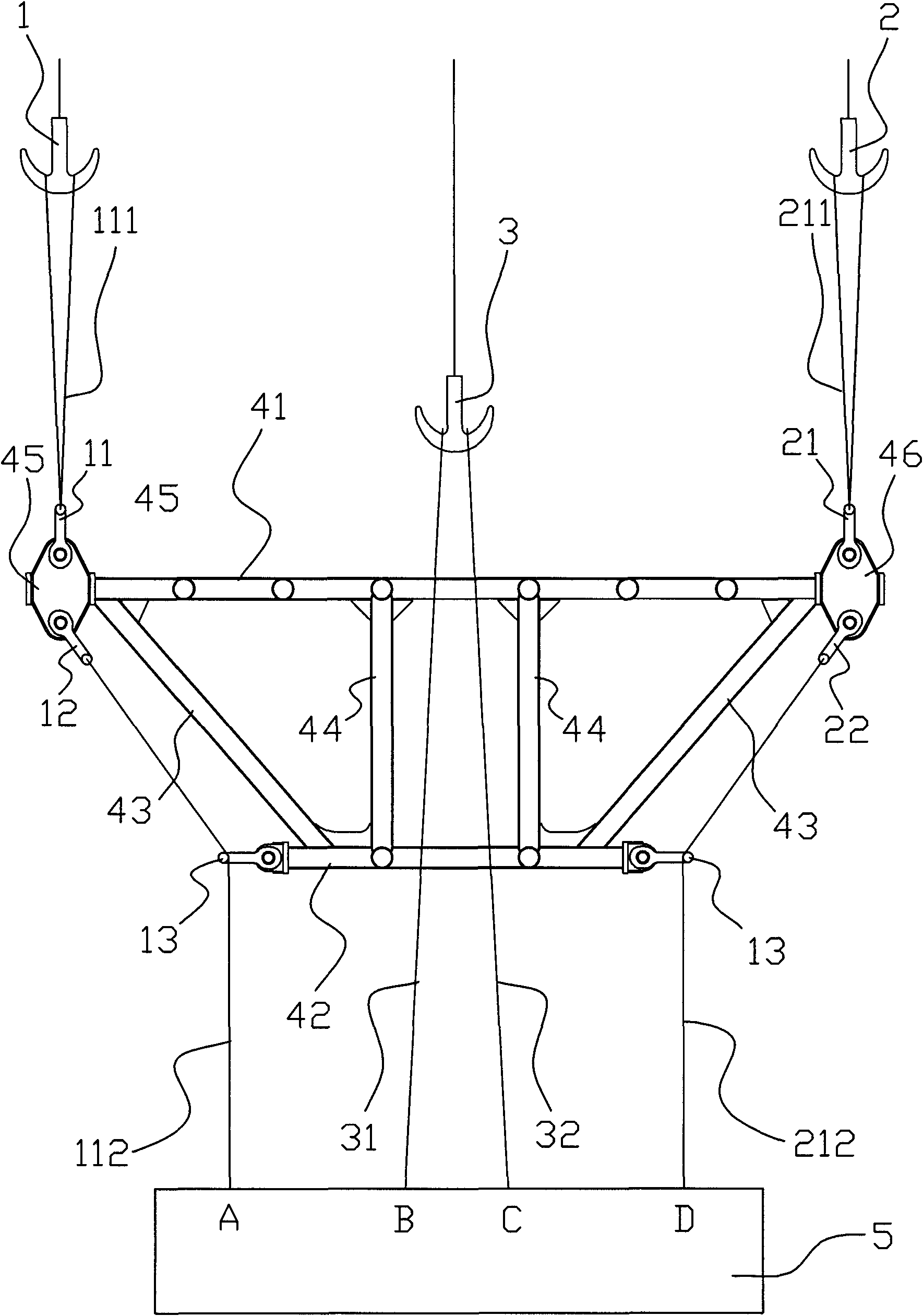

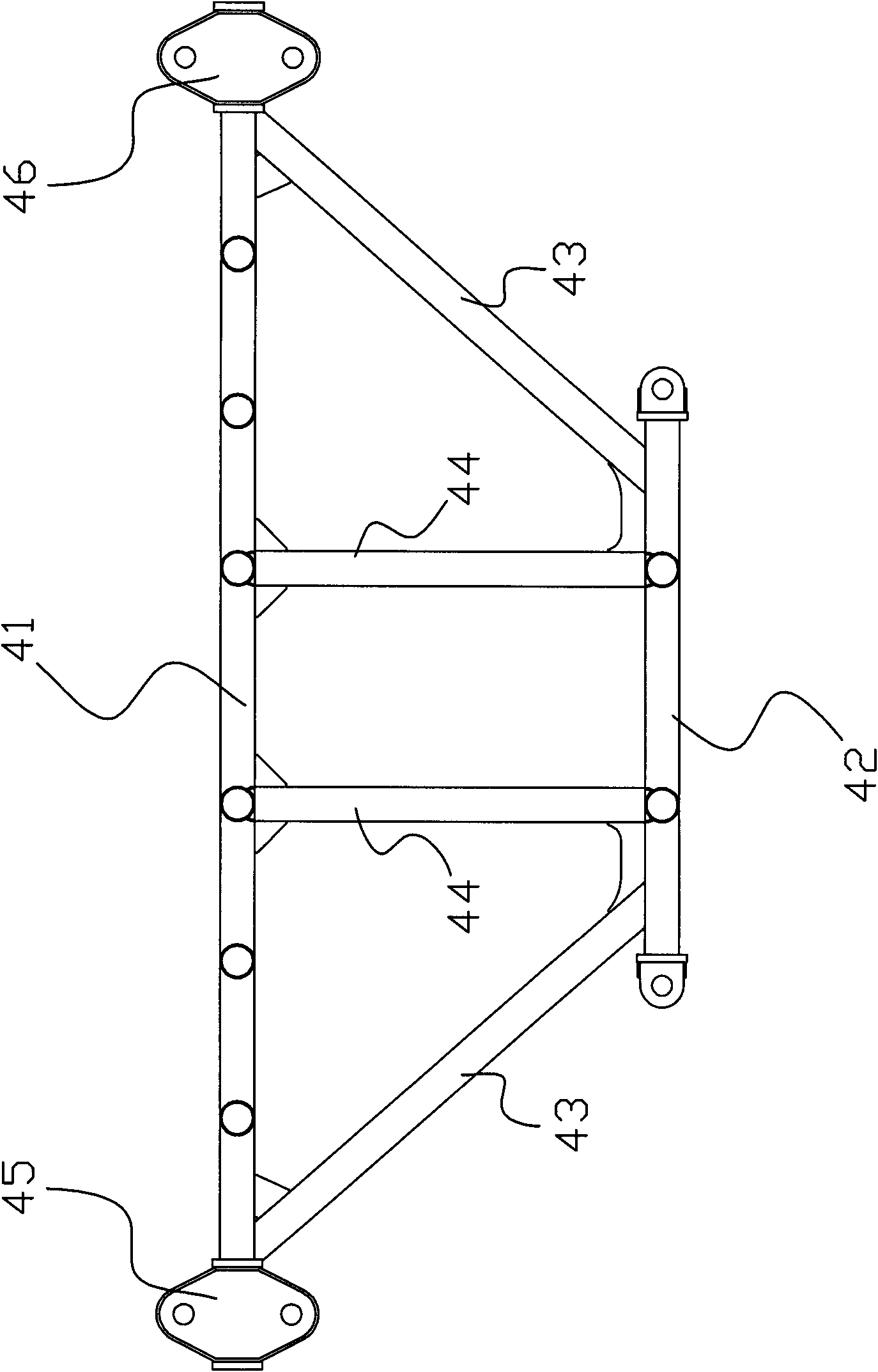

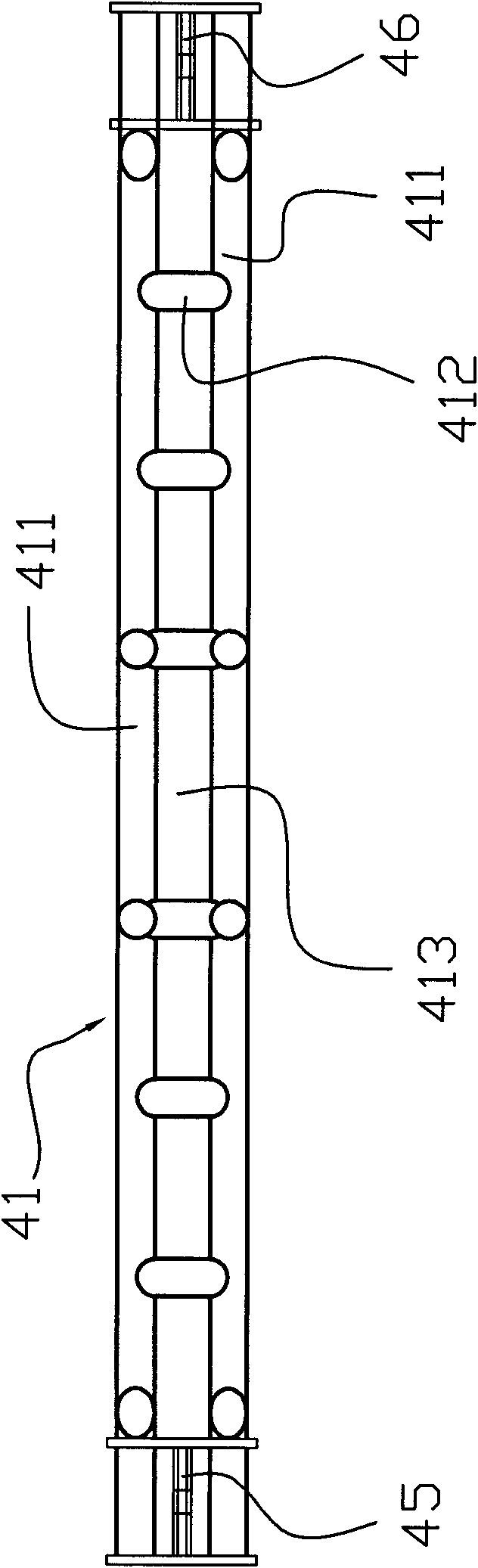

Suspension apparatus of ship main engine

The invention relates to a suspension apparatus of a ship main engine. The suspension apparatus comprises wire ropes, and further comprises a suspension frame. A left end on the top of the suspension frame is connected with a first traction part through a first wire rope (111). A right end on the top of the suspension frame is connected with a second traction part through a second wire rope (211). A left end on the bottom of the suspension frame extends to a first suspension point (A) of a main engine (5) through a third wire rope (112). A right end on the bottom of the suspension frame extends to a fourth suspension point (D) of the main engine (5) through a fourth wire rope (212). A middle portion of the suspension frame is provided with space, wherein a middle wire rope passes through the middle portion of the suspension frame from top to bottom, and extends to a corresponding second suspension point (B) and a corresponding third suspension point (C) in the space. An upper end of the middle wire rope is connected with a third traction part. Compared to the prior art, the apparatus provided by the present invention has the following advantages that: the structure of the apparatus is simple; the pulley block is not required; the apparatus is easy to be used; the production cost of the apparatus is low; the suspension beam structure of the apparatus is solid and stable so as to provide longer service life.

Owner:ZHEJIANG ZHENGHE SHIPBUILDING

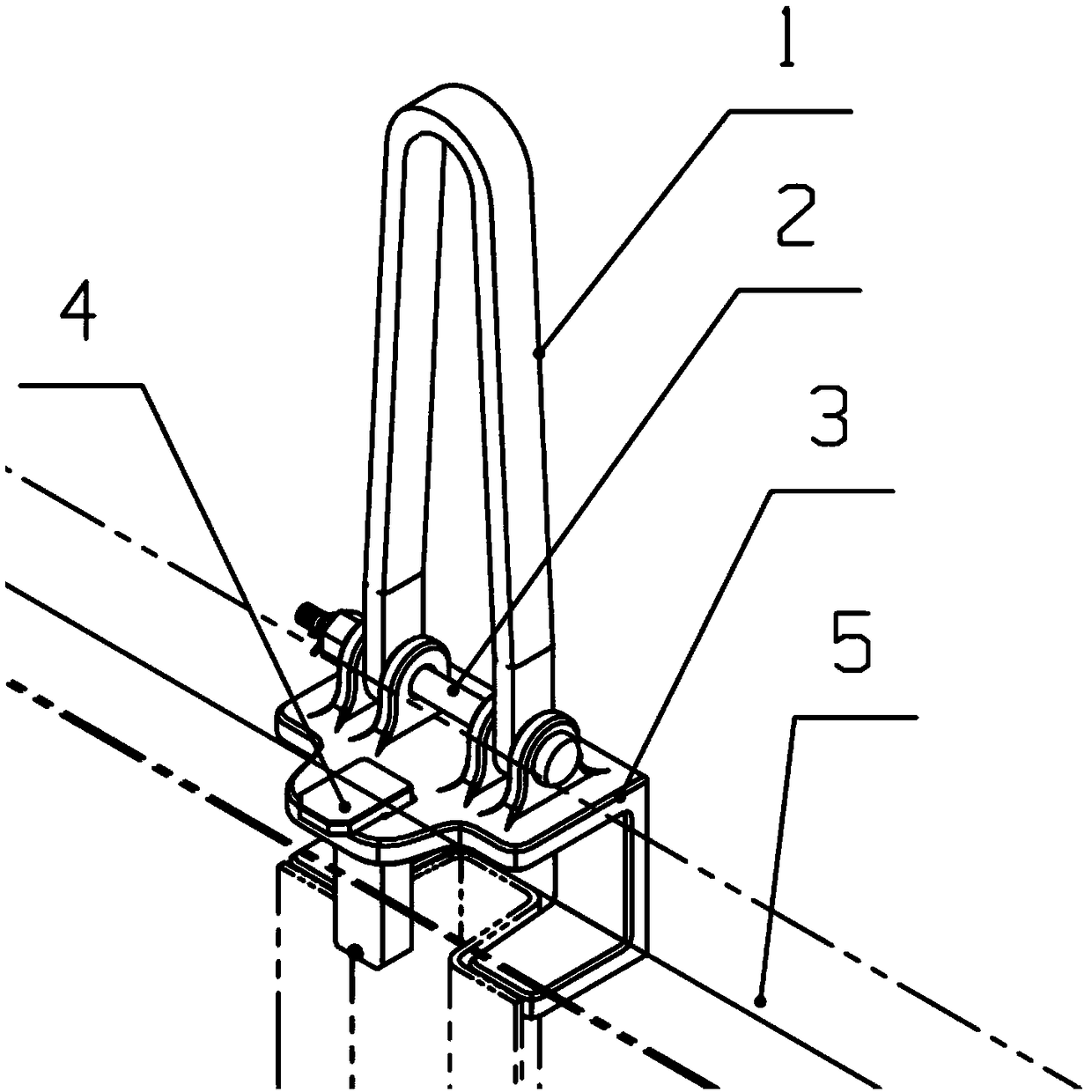

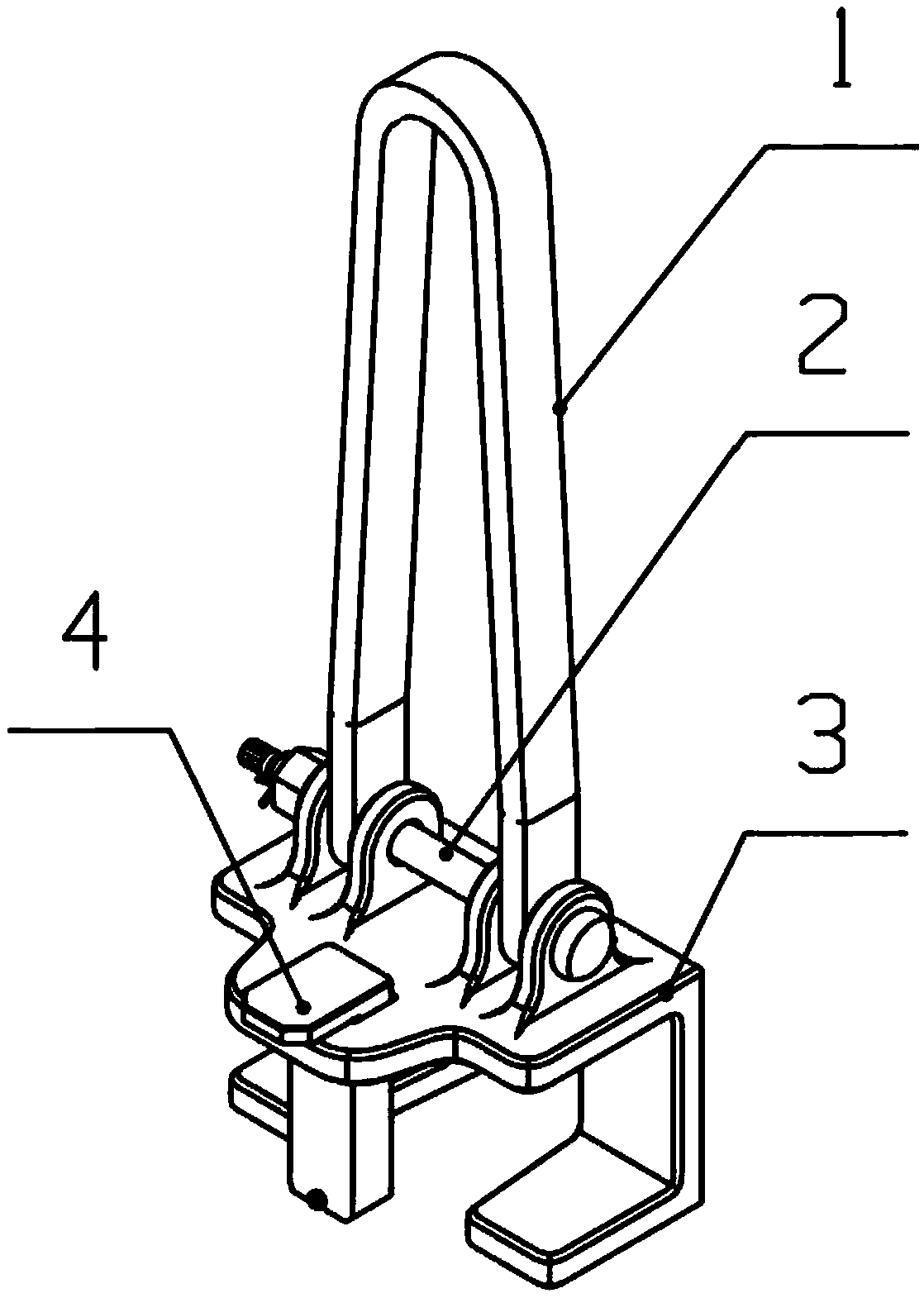

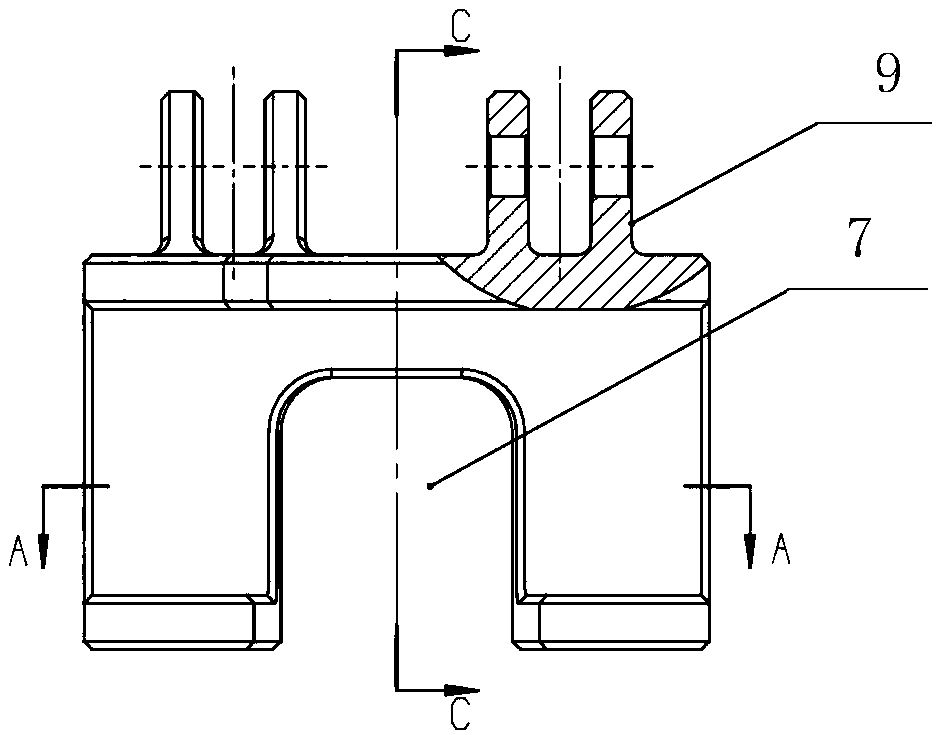

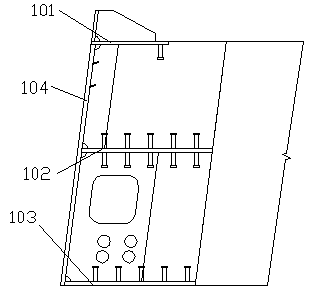

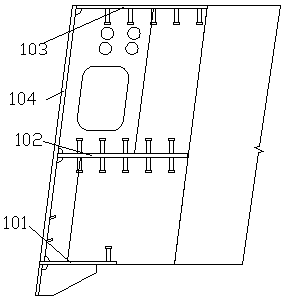

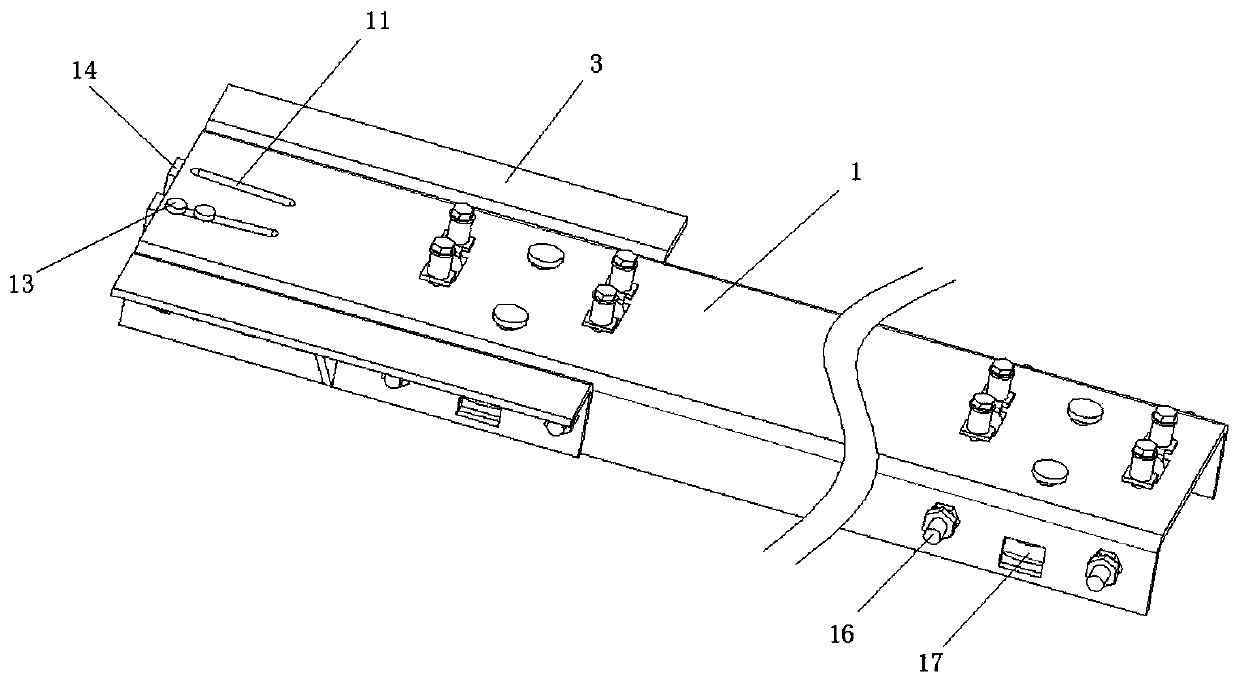

Special lifting appliance of side wall of coal conveying open wagon

PendingCN108750921AReliable connectionOvercome production bottlenecksLoad-engaging elementsCoalHigh intensity

The invention discloses a special lifting appliance of the side wall of a coal conveying open wagon. The lifting appliance comprises a double-buckle flexible lifting belt, a high-strength bolt connecting pair, an installing and clamping groove body and a clamping block; the double-buckle flexible lifting belt is connected with the installing and clamping groove body through the high-strength boltconnecting pair, and the high-strength bolt connecting pair comprises a screw rod and a nut; the installing and clamping groove body is of a double-clamping-groove structure and comprises a large clamping groove and a small clamping groove, a square opening through hole is formed in the center position, close to the front, of the top of the installing and clamping groove body, two pairs of ear plates are fixedly arranged on the positions, near the rear part, of the top of the installing and clamping groove body in a left-and-right symmetrical mode, and through holes matched with the screw rodof the high-strength bolt connecting pair are orrespondingly formed in the opening end parts of the ear plates and the opening end parts of the double-buckle flexible lifting belt respectively; the screw rod penetrates through the through holes of the ear plates and the through holes of the double-buckle flexible lifting belt; and the clamping block penetrates into the square opening through holein the top of the installing and clamping groove body. The special lifting appliance is small in structure, light in weight, convenient to operate and capable of greatly reducing the labor intensity during lifting of an operator, the production time is shortened, the production bottleneck is overcome, and the production efficiency is improved.

Owner:CRRC MEISHAN

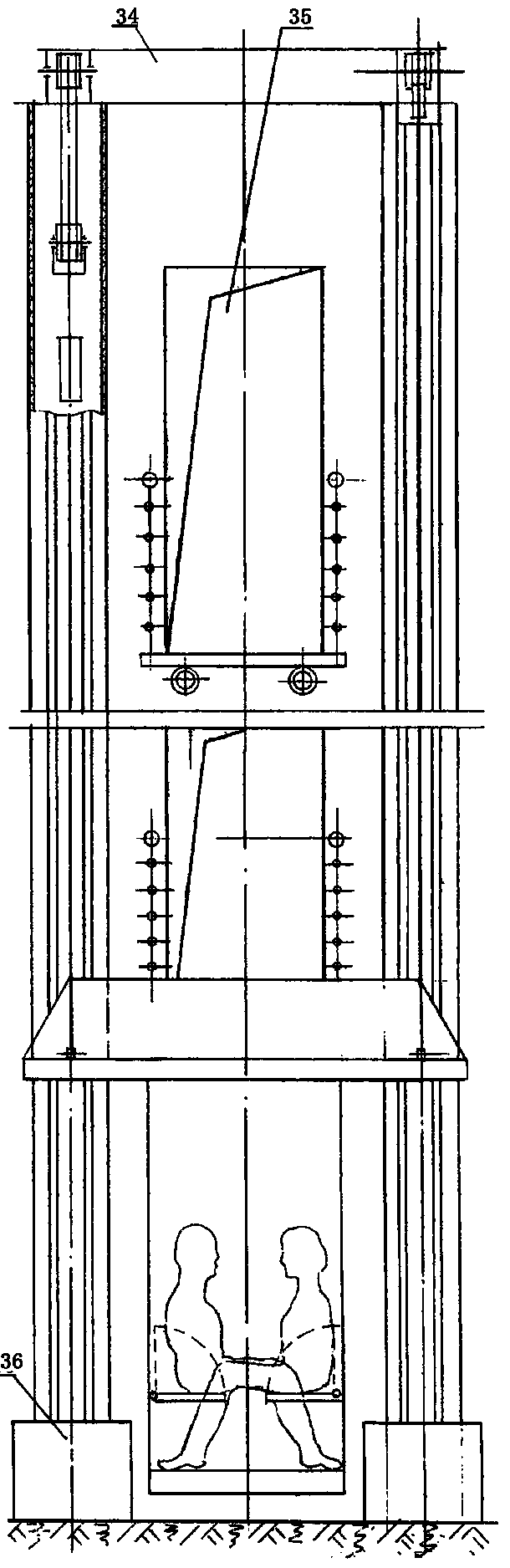

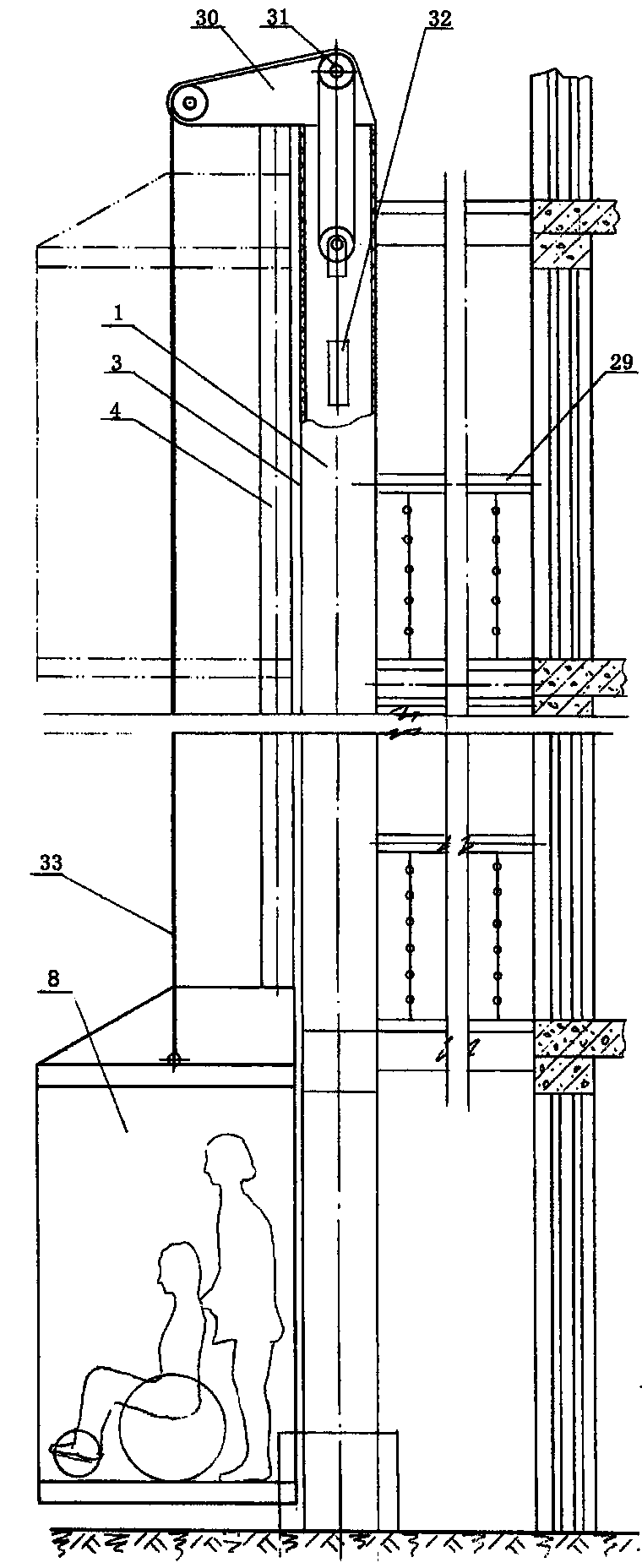

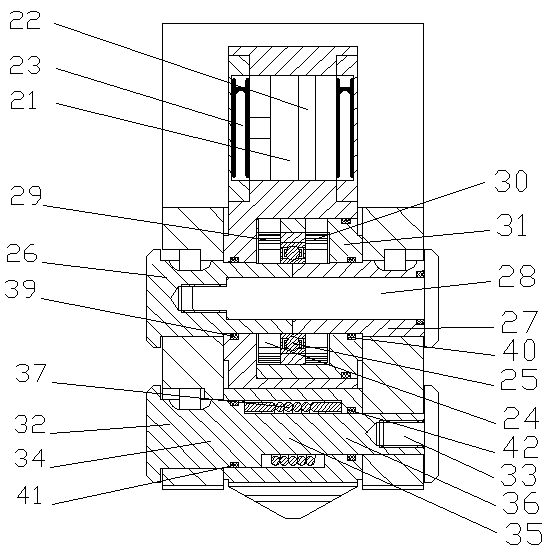

Safe and practical elevator for middle-aged and aged people without car shaft and machine room

InactiveCN108116962AAdapt to physical and mental enduranceEnsure lifting safetyBuilding liftsSustainable buildingsLow speedCoupling

The invention provides a safe and practical elevator for middle-aged and aged people without a car shaft and a machine room and relates to an elevator. An elevator car (9) is installed below a car roof cover (6), and a power driving device for mounting the elevator is mounted on the car roof cover (6). A storage battery (15) is connected to a permanent magnet direct current motor (8), the permanent magnet direct current motor (8) is connected with a bevel gear box (5) through a reducer (7), a transmission shaft (12), a coupling (11), a driving chain wheel (14), a chain (13), a driven chain wheel (10), and two cones with opposite rotating directions are mounted at the reversed vertical output shaft end of the bevel gear box (5). According to the safe and practical elevator, the car liftingis achieved through the cone rotation and climbing along a rack; and after the elevator completes user loading, the car lifts to the top end for use and is automatically charged. The shutdown and braking are performed through a linkage mechanism. The elevator is free of the car shaft and the machine room and free of barrier, is at a low speed and has a light load, and the car is suitable for use by middle-aged and aged people.

Owner:张振基

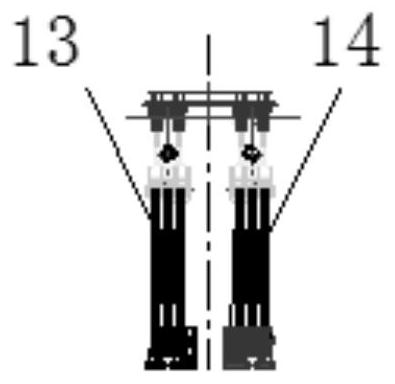

Crane boom and using method thereof

PendingCN111874816AVarious forms of exerciseNo torqueLoad-engaging elementsCranesPropellerControl theory

According to the crane boom, one end of a first limb rod and one end of a second limb rod are hinged to a rotary table, and the other end of the first limb rod makes contact with the other end of thesecond limb rod. A first lifting hook group is arranged at the other end of the first limb rod, and a second lifting hook group is arranged at the other end of the second limb rod. A first variable-amplitude winding mechanism bypasses the top end of a propeller strut, and the two ends of the first variable-amplitude winding mechanism are connected with a first variable-amplitude winch and the other end of the first limb rod respectively and used for driving the first limb rod to rotate around a hinge point in a variable-amplitude mode; a second variable-amplitude winding mechanism bypasses thetop end of the propeller strut, and the two ends of the second variable-amplitude winding mechanism are connected with a second variable-amplitude winch and the other end of the second limb rod correspondingly and used for driving the second limb rod to rotate around the hinge point in a variable-amplitude mode; a first hoisting winding mechanism bypasses the top end of the propeller strut, and two ends of the first hoisting winding mechanism are respectively connected with a first hoisting winch and the first lifting hook group and used for driving the first lifting hook group to lift; and asecond hoisting winding mechanism bypasses the top end of the propeller strut, and two ends of the second hoisting winding mechanism are respectively connected with the first hoisting winch and the second lifting hook group and used for driving the second lifting hook group to lift.

Owner:TAIZHONG TIANJIN BINHAI HEAVY MACHINERY

Steel cap installation method

ActiveCN107620324AEasy to transportEasy to liftArtificial islandsUnderwater structuresMetallurgyImmersed tube

The invention relates to the technical field of immersed tube tunnels, in particular to a steel cap installation method. The installation method comprises the steps that a steel cap is divided into aplurality of sections, and the sections are hoisted from bottom to top in a left-right symmetrical mode; and the hoisted-in-place sectional steel caps are positioned and welded. According to the steelcap installation method, the steel cap is divided into the sections for being installed, so that the steel cap is conveniently transported and hoisted, and the construction difficulty is greatly reduced; the construction efficiency is improved, and the construction risk is also reduced; the sections are hoisted from bottom to top, the firstly-installed steel cap is conveniently positioned and adjusted, it is ensured that the steel cap has the high precision, so that the late-installed steel cap also has the good precision, and it is ensured that design requests are met after the steel cap iswholly hoisted; and meanwhile, the bottom plate section of the firstly-hoisted steel cap supports the sections of the late-hoisted steel cap, and the subsequently-installed sections are conveniently constructed.

Owner:THE SECOND ENG COMPANY OF CCCC FOURTH HARBOR ENG +3

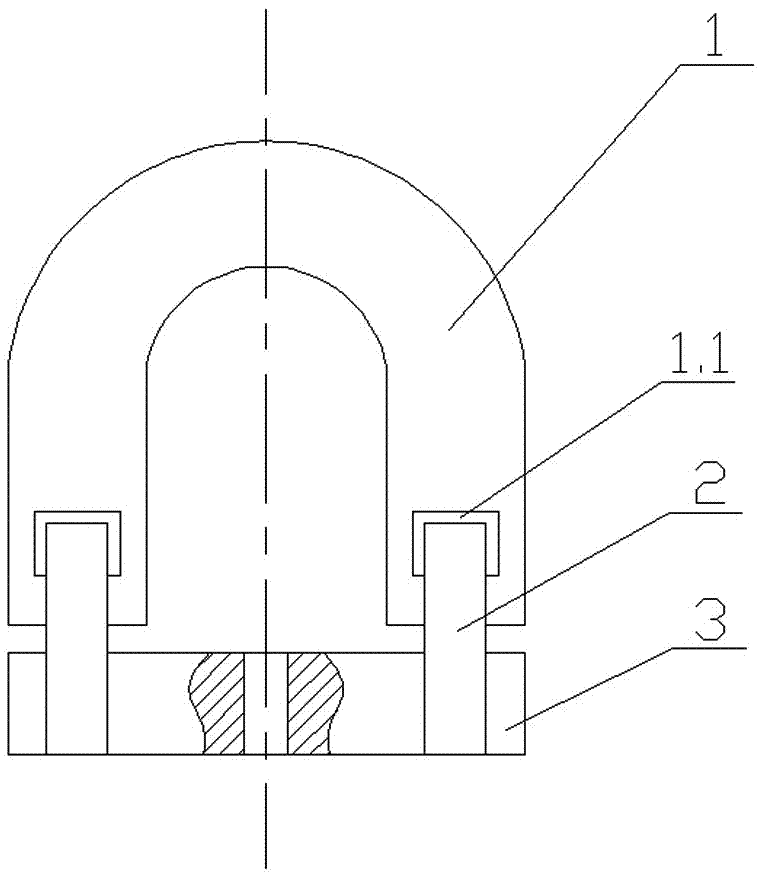

Anti-falling pipe fitting lifting device with protection structure for aviation equipment production

PendingCN113753746AProtective structureImprove positional stabilityBase supporting structuresBraking devices for hoisting equipmentsAviationMarine engineering

The invention discloses an anti-falling pipe fitting lifting device with a protection structure for aviation equipment production. The anti-falling pipe fitting lifting device comprises a base body, a driving assembly, an abutting part, a butt joint handle and a fixing part, wherein the driving assembly is mounted at the upper end of the base body through a bolt; a lifting rope is mounted at the output end of the driving assembly in a nested manner, and the lower end of the lifting rope is fixedly connected with a supporting part; meanwhile, the supporting part is connected with the outer end of the base body; and a first pull rope is mounted at the outer side of the base body in a nested manner, and the first pull rope is connected with the outer end of the supporting part. According to the anti-falling pipe fitting lifting device with the protection structure for aviation equipment production, the lifting rope drives the supporting part to upwards lift an object, the first pull rope moving to a corresponding state is wound along with the supporting part, then a limiting part at the tail end is driven to move in the opposite direction, so that the inner end of a pipe fitting is subjected to self-adaptive nested contact; and the positioning stability is continuously improved along with the increase of the height, therefore, the lifting safety is ensured.

Owner:张绅

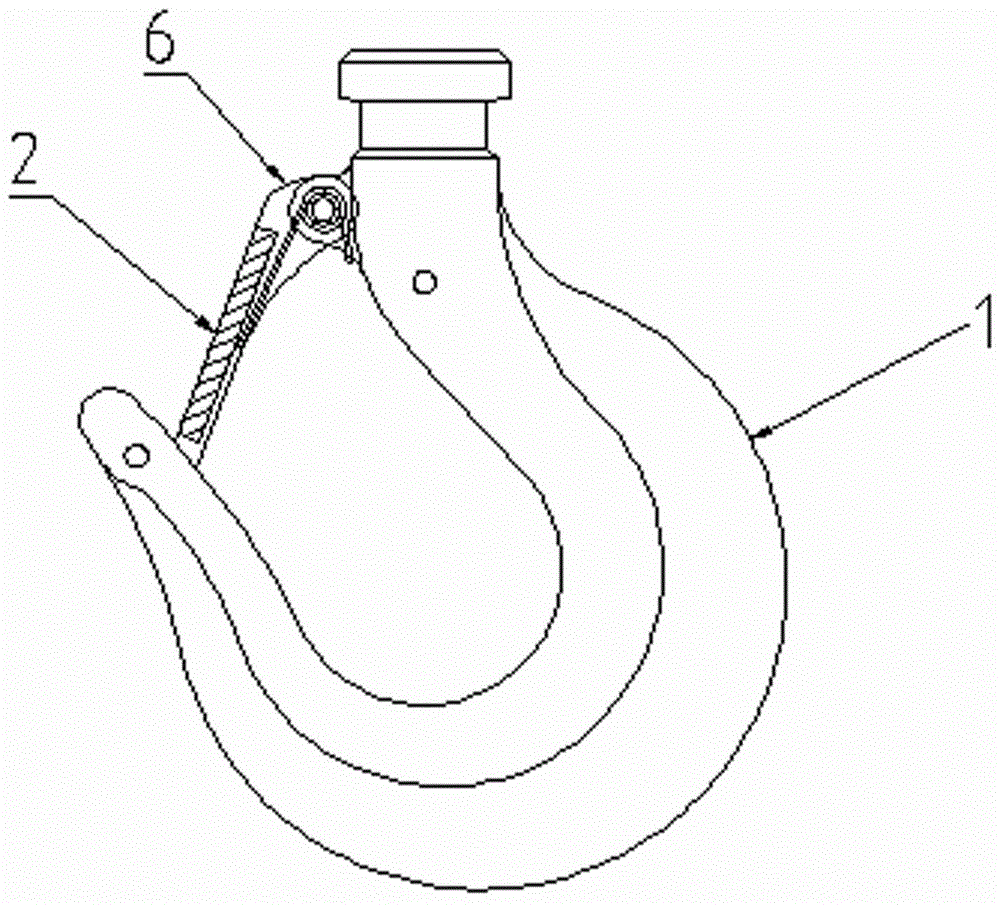

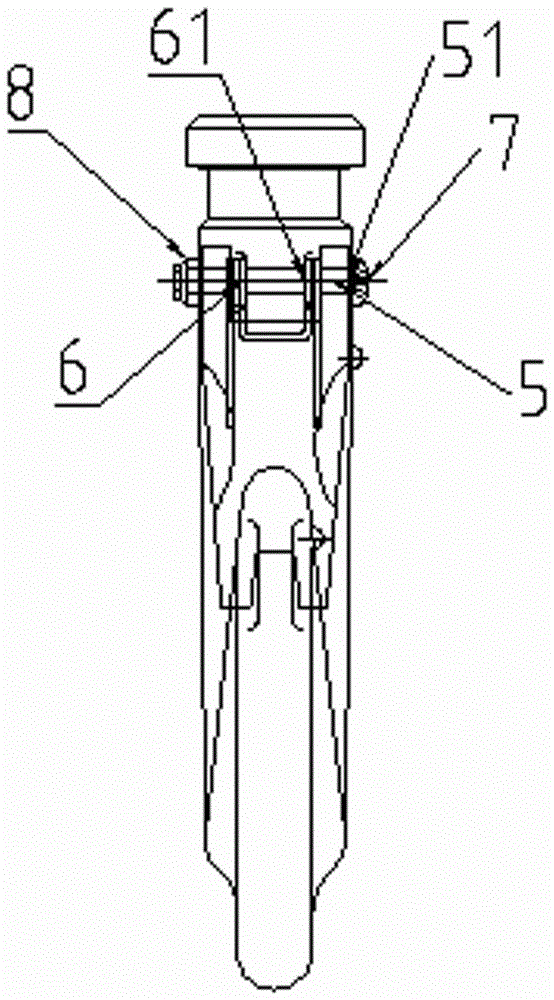

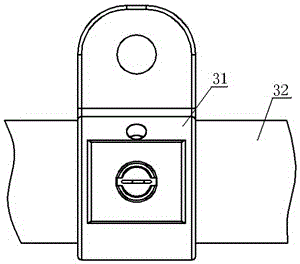

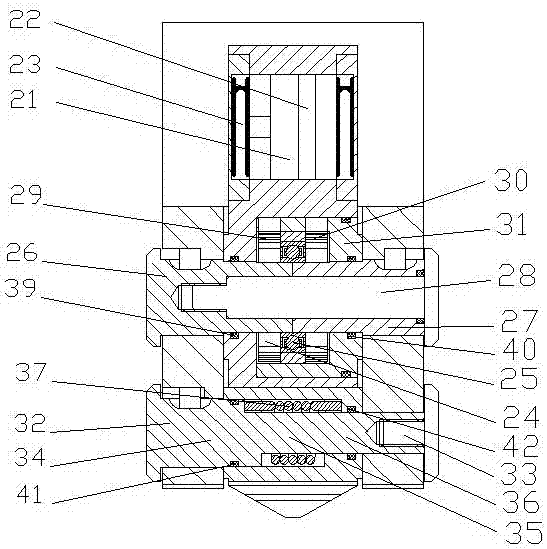

Falling-off prevention hook

InactiveCN105923536APrevent disengagementImprove safety factorLoad-engaging elementsEngineeringTorsion spring

The invention discloses a falling-off prevention hook. The falling-off prevention hook comprises a hook body and a rope clamping plate. The hook tail portion of the hook body is rotationally connected with the tail end of the rope clamping plate. A torsion spring is arranged between the hook body and the rope clamping plate so that the rope clamping plate can have outward-rotating elastic force. A blocking wall is arranged on the hook head position of the hook body and makes contact with the top end face of the rope clamping plate. According to the falling-off prevention hook, the rope clamping plate is hinged to the hook tail position of the hook body, the torsion spring is arranged between the rope clamping plate and the hook body, outward tension of the rope clamping plate is kept, the blocking wall is arranged on the position, in cooperation with the hook head of the hook body, of the top end of the rope clamping plate and makes contact with the rope clamping plate face, the safety factor is increased, the rope clamping plate is effectively prevented from being separated from the hook body, and hoisting safety is guaranteed.

Owner:杭州维多利机械有限公司

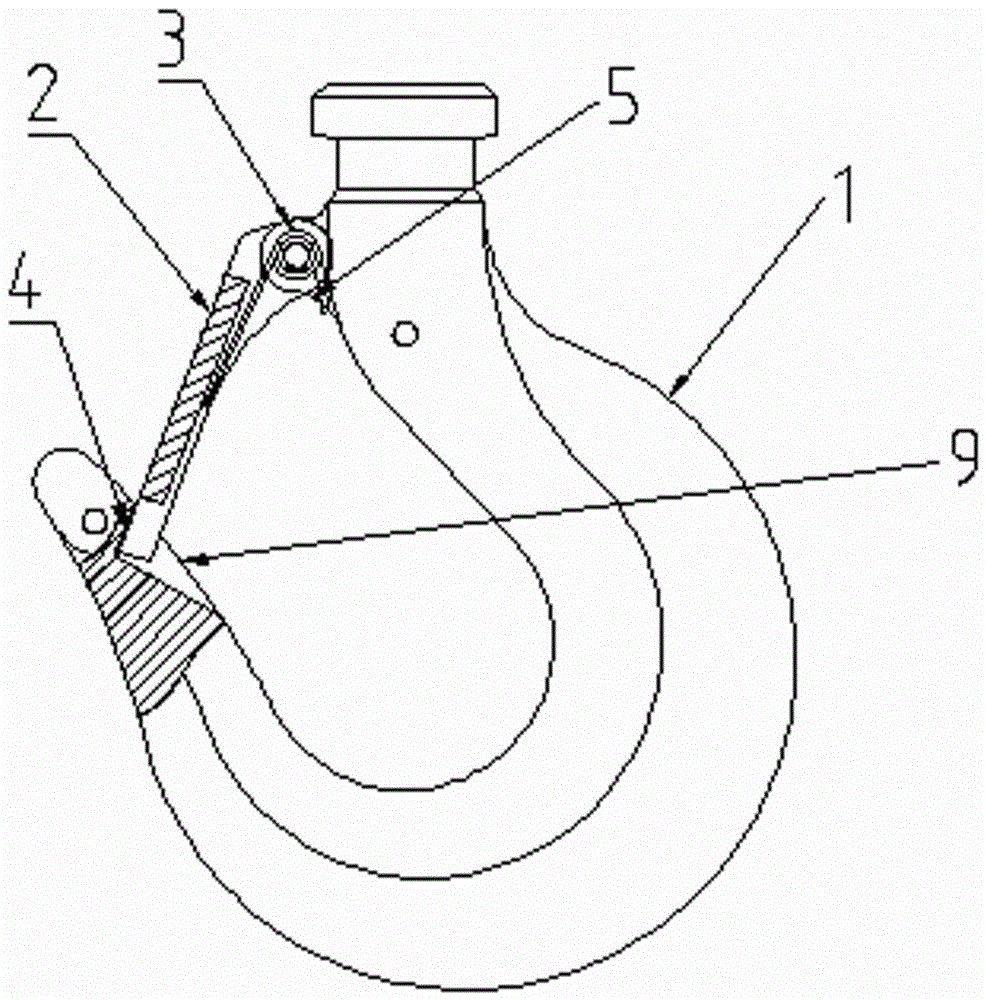

Multi-leg chain rigging set

InactiveCN104386572ANo slippageEnsure lifting safetyLoad-engaging elementsEngineeringMechanical engineering

The invention discloses a multi-leg chain rigging set. The multi-leg chain rigging set comprises an end ring, a plurality of chains and a plurality of lifting hooks, wherein the end ring is of a pear shape, a plurality of spacing grooves are formed in the pear-shaped end ring, a plurality of chains are connected with the end ring by a plurality of connecting rings respectively, the connecting rings are circular rings with same structure, the circular walls of the upper ends of the connecting rings are embedded into the corresponding spacing grooves respectively, and the lifting hooks are equal to the chains in quantity and are connected at the ends of the chains respectively. After the mode is adopted, a plurality of chains are fixedly connected with the end ring by the connecting rings in a spacing manner, no chain position change is caused during hoisting, and the hoisting safety and the hoisting reliability are ensured.

Owner:江苏西窗幕墙装饰工程有限公司

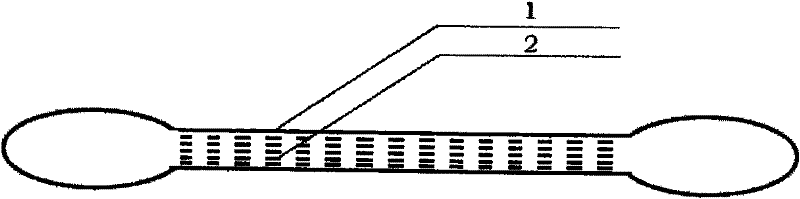

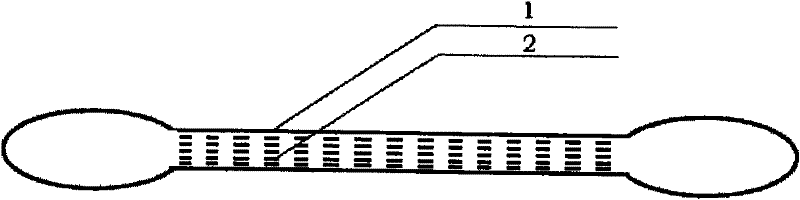

High-molecular-weight polyethylene hoisting rope

InactiveCN102234945AAbrasion-resistant and strong tensile strengthReduce weightBraidTextile cablesEngineeringPolyethylene

The invention discloses a high-molecular-weight polyethylene hoisting rope which comprises a high-molecular-weight polyethylene hoisting rope body (2), wherein the high-molecular-weight polyethylene hoisting rope body (2) is formed by weaving multiple high-molecular-weight polyethylene monofilaments; and a resin layer (1) is arranged on the surface of the high-molecular-weight polyethylene hoisting rope body (2). The high-molecular-weight polyethylene hoisting rope disclosed by the invention has high tensile strength, light weight and high wear resistance, is convenient to use, and can ensure hoisting safety.

Owner:王宏贵

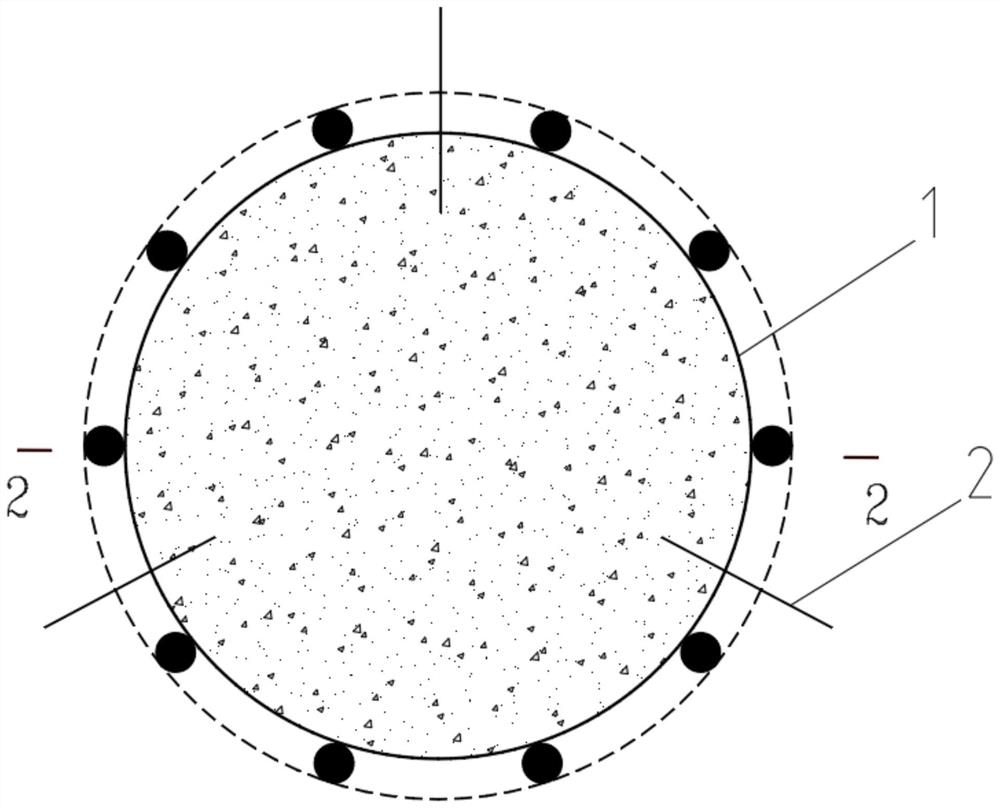

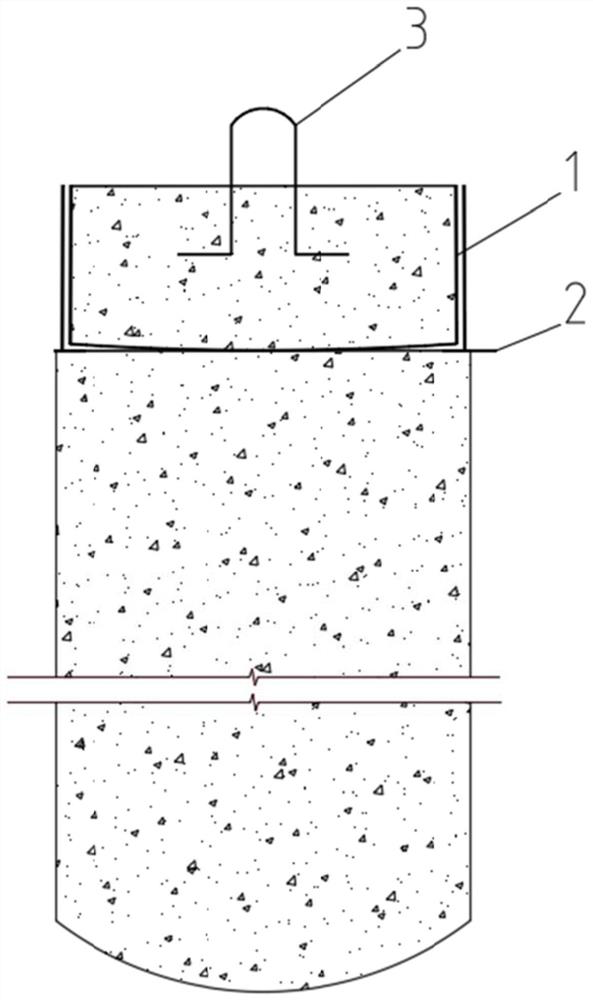

Construction method convenient for breaking pile head of cast-in-place pile

The construction method comprises the steps that before a cast-in-place pile reinforcement cage is installed and concrete is poured, an isolation pipe is installed in a to-be-broken section of the cast-in-place pile head, the outer diameter of the isolation pipe is matched with the inner diameter of the reinforcement cage, and the length of the isolation pipe is not smaller than the height of the to-be-broken section; the bottom of the isolation pipe is flush with the bottom of the to-be-broken section; after the isolation pipe is installed, concrete is poured into the cast-in-place pile reinforcement cage to the top of the cast-in-place pile reinforcement cage, and the concrete formed in the isolation pipe of the to-be-broken section is a cast-in-place pile head; after the strength of the concrete meets the breaking requirement, a plurality of wedge holes are evenly formed in the bottom of the pile head of the cast-in-place pile in the circumferential direction, and a wedge is driven into each wedge hole till the pile head of the cast-in-place pile is broken by the wedges; and the broken cast-in-place pile head is hoisted out, and breaking of the cast-in-place pile head is completed. The main reinforcement of the cast-in-place pile head is effectively prevented from being damaged in the breaking process, and the time for breaking the cast-in-place pile head is remarkably prolonged.

Owner:SCEGC MECHANIZED CONSTR GRP COMPANY

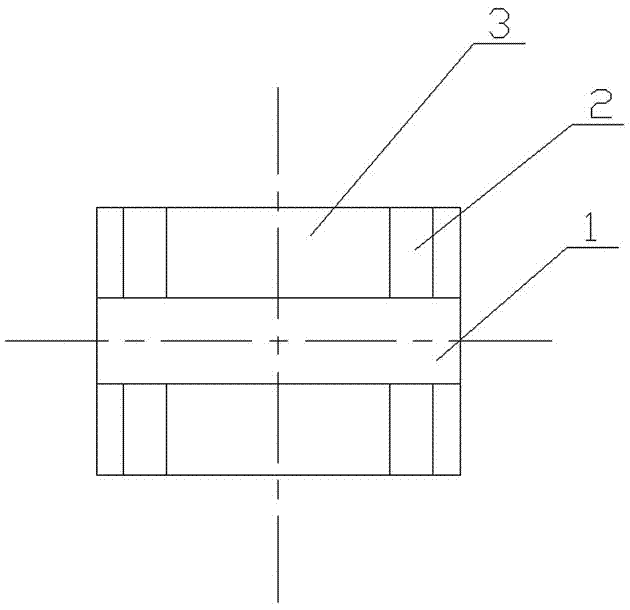

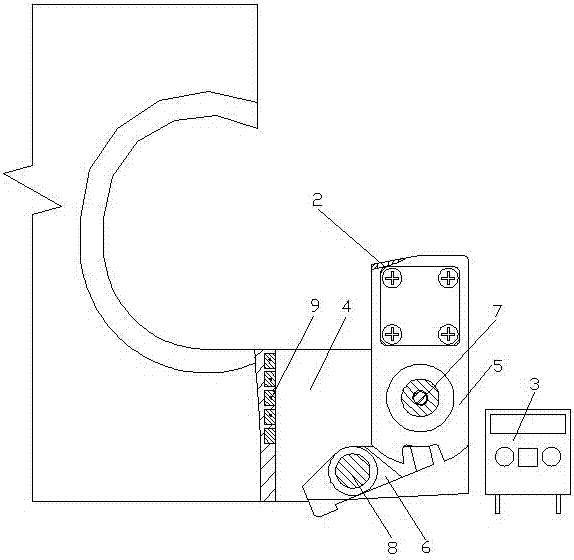

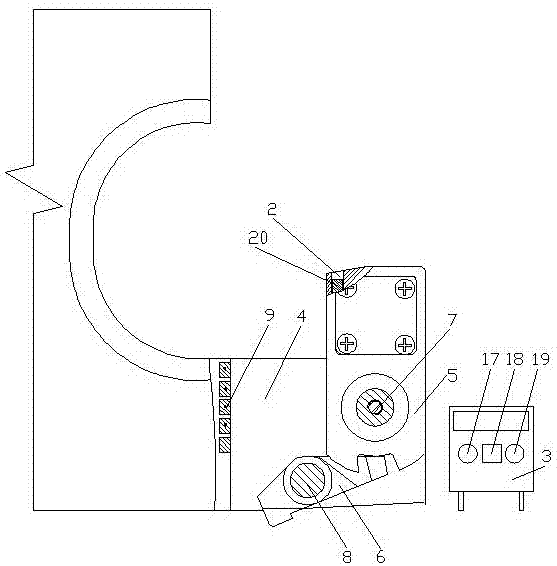

Transformer pulling board

InactiveCN106057450AEnsure lifting safetyReduce dosageTransformers/inductances coils/windings/connectionsEngineeringMechanical engineering

The invention discloses a transformer pulling board which is characterized by comprising a pulling board (1), a clamping member and supporting boards (3) on the clamping member; the clamping member comprises an upper clamping member(2) and a lower clamping member (4); two ends of the pulling board (1) are arc-shaped; the end parts of the upper clamping member (2) and the lower clamping member (4) are provided with arc-shaped grooves which are matched and can be inserted in the arc-shaped structure. According to the transformer pulling board provided by the invention, the arc-shaped structure of the pulling board and the clamping member are connected in an embedded mode, and the arc-shape structure has a self-spacing function to restrict the displacement of the pulling board in vertical direction; the supporting boards welded on the upper clamping member and the lower clamping member are used in preventing the deformation of the pulling board and displacement of the pulling board in forwards and backwards direction during the lifting process of the transformer; The upper clamping member and the lower clamping member of the transformer pulling board are finally matched with the pulling board wherein the matched surface is leveled; at the same time, the pulling board and the clamping member are on one surface which reduces the consumption of transformer clamping member insulation; The transformer pulling board has simple processing technology and structure, and is convenient for assembly.

Owner:CEEG JIANGSU

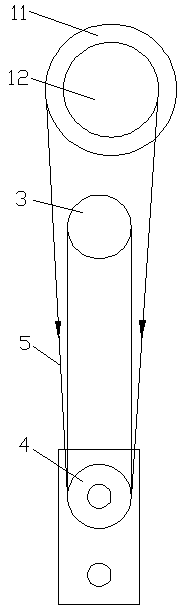

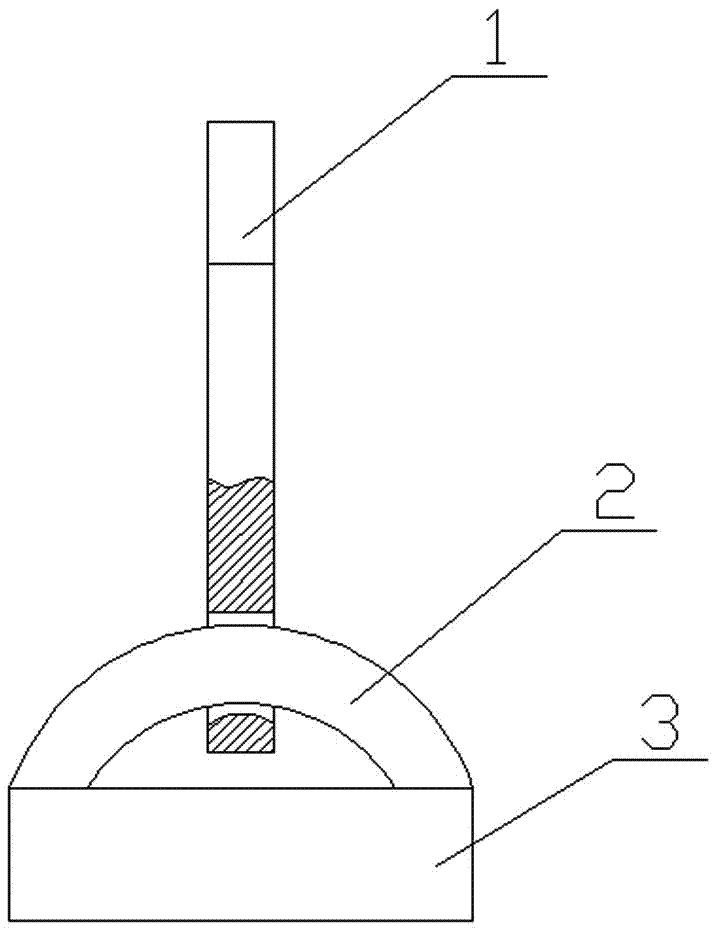

Differential windlass lifting device

The invention discloses a differential windlass lifting device, and belongs to the field of lifting machinery. The differential windlass lifting device comprises a bearing base, a drum shaft, a fixedpulley module, a movable pulley module, a lifting rope and a speed reducer. The differential windlass lifting device is characterized by further comprising a differential drum set, a coupling and a motor; the differential drum set is fixed on the drum shaft, and is integrally molded by a first differential drum and a second differential drum; the diameter of the first differential drum is larger than the diameter of the second differential drum; one end of the lifting rope is fixed at the end part of the first differential drum, and the other end is fixed at the end part of the second differential drum; one end of the drum shaft is connected with the bearing base, and the other end is connected with the speed reducer; one end of the coupling is connected with the speed reducer, and the other end is connected with the motor; and a brake is mounted on the coupling. Through use of the differential drum set and a specific rope winding mode, the high-capacity and low-speed lifting of the lifting mechanism can be realized, and the lifting stability and safety are guaranteed.

Owner:SINOHYDRO JIAJIANG HYDRAULIC MACHINERY +1

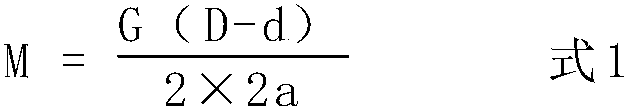

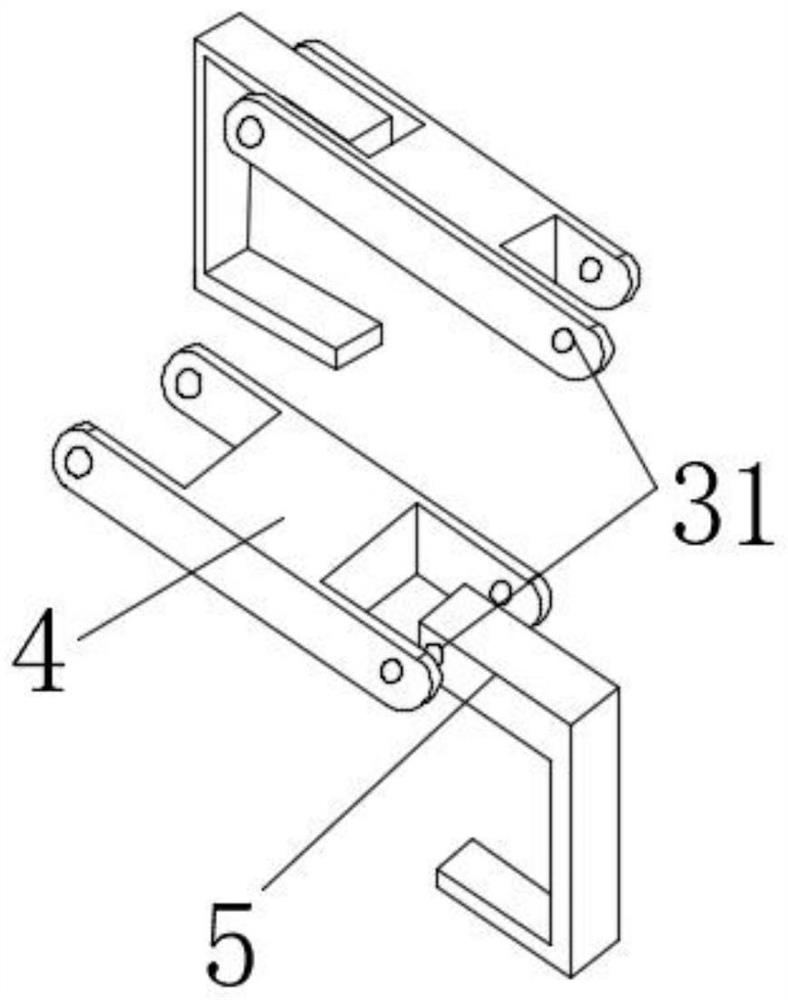

Hinged lifting appliance

InactiveCN106995184ASimple structureEasy to manufactureLoad-engaging elementsSheet steelDegrees of freedom

The invention discloses a hinged lifting appliance which comprises a lifting buckle, a ring buckle and a baseplate, wherein an inverted U-shaped steel component serves as the lifting buckle; transverse rectangular through holes are correspondingly formed in the similar positions of both ends of the open side of the lifting buckle; a rectangular steel plate serves as the baseplate; open grooves along the thickness direction are correspondingly formed in both ends of the long-edge side walls of the baseplate; a through hole penetrating through the plate surface of the baseplate is formed in the middle of the plate surface; a semicircular steel component serves as the ring buckle; the ring buckle penetrates through the rectangular through hole; both ends of the ring buckle span the baseplate and are embedded in the open grooves; and the ring buckle and the baseplate are fixedly connected at the junctions, thereby forming a lifting buckle and baseplate hinged-connection structure. The hinged lifting appliance disclosed by the invention adopts the hinged-connection structure; the degree of freedom among all the components is relatively high; when the lifting buckle is deflected, pre-embedded bolts of a lifted main building component can be conveniently mounted and dismounted by using a tool; and accordingly, the mounting and dismounting work efficiency can be improved.

Owner:江苏宇辉新材料集团有限公司 +1

Lifting appliance for crane

ActiveCN112520558AEasy to liftIncrease the areaLoad-engaging elementsEngineeringStructural engineering

The invention provides a lifting appliance for a crane. The lifting appliance comprises a clamping mechanism, the clamping mechanism is composed of a rectangular plate and a plurality of partition plates, the multiple partition plates are fixedly arranged in the rectangular plate, limiting holes I are formed in the positions, close to the lower ends of one sides, of the outer surfaces of the frontends of the multiple partition plates close to the middle, the front limiting hole I and the rear limiting hole I are opposite in position, I-shaped connecting frames are movably connected into the limiting holes I, and limiting holes II are further formed in the positions, close to the two sides, of the outer surfaces of the front ends and the rear ends of the I-shaped connecting frames. The lifting appliance has the advantages that the grabbing area is large, the grabbing force is stable, large coil steel can be conveniently lifted, the balance of a lifting appliance body is reinforced through a front baffle structure and a rear baffle structure, the phenomenon that the coil steel topples out from the front end and the rear end in the lifting process, and consequently danger is caused can be avoided, the coil steel of different layer heights can be conveniently reinforced and limited through a limiting structure, compression and storage are facilitated, a lifting mechanism can keepbalance in the lifting process, accumulation of a large amount of rainwater is prevented, rusting and corrosion are reduced, and lifting safety is guaranteed.

Owner:ZHUHAI TIANLI HEAVY IND

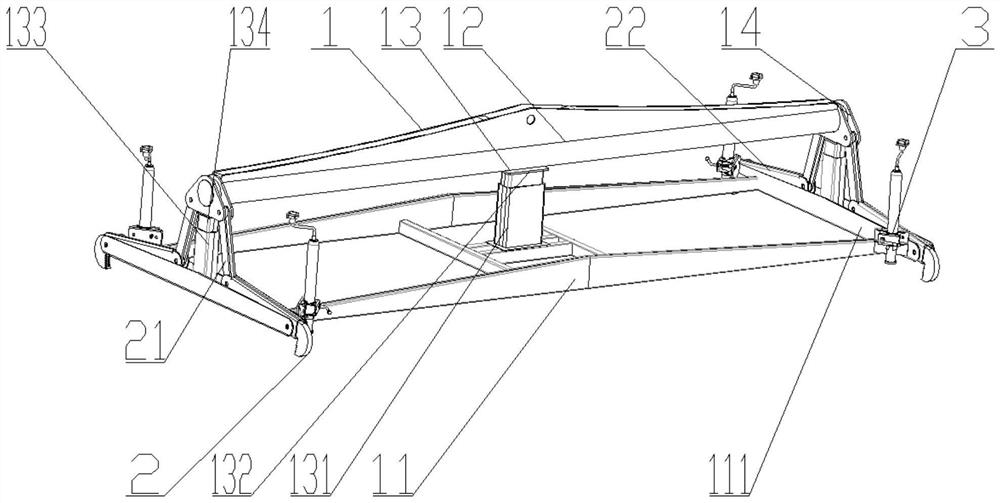

Fast, efficient and safe flat plate lifting appliance

The invention belongs to the technical field of lifting appliances, solves the technical problem of poor stability when a lifting appliance lifts a flat plate in the prior art, and provides a fast, efficient and safe flat plate lifting appliance which comprises a mounting mechanism and a grabbing mechanism; the mounting mechanism comprises a main body frame and a cross beam, the main body frame is rectangular, the cross beam is arranged in the center of the upper portion of the main body frame, a telescopic sleeve is connected between the cross beam and the main body frame, the two ends of the cross beam are each provided with a hinge frame, and the two ends of the main body frame are each provided with a hinge groove with an upward opening in the width direction; the two ends of the hinge groove communicate, and the hinge groove is located under the hinge frame; and the grabbing mechanism comprises four link rods and four grabbing rods, and every two of the four link rods and every two of the four grabbing rods form two groups to form four grabbing parts. The fast, efficient and safe flat plate lifting appliance has the advantage of being high in stability during flat plate lifting.

Owner:方霄

An auxiliary device for dismantling and assembling electric poles

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +3

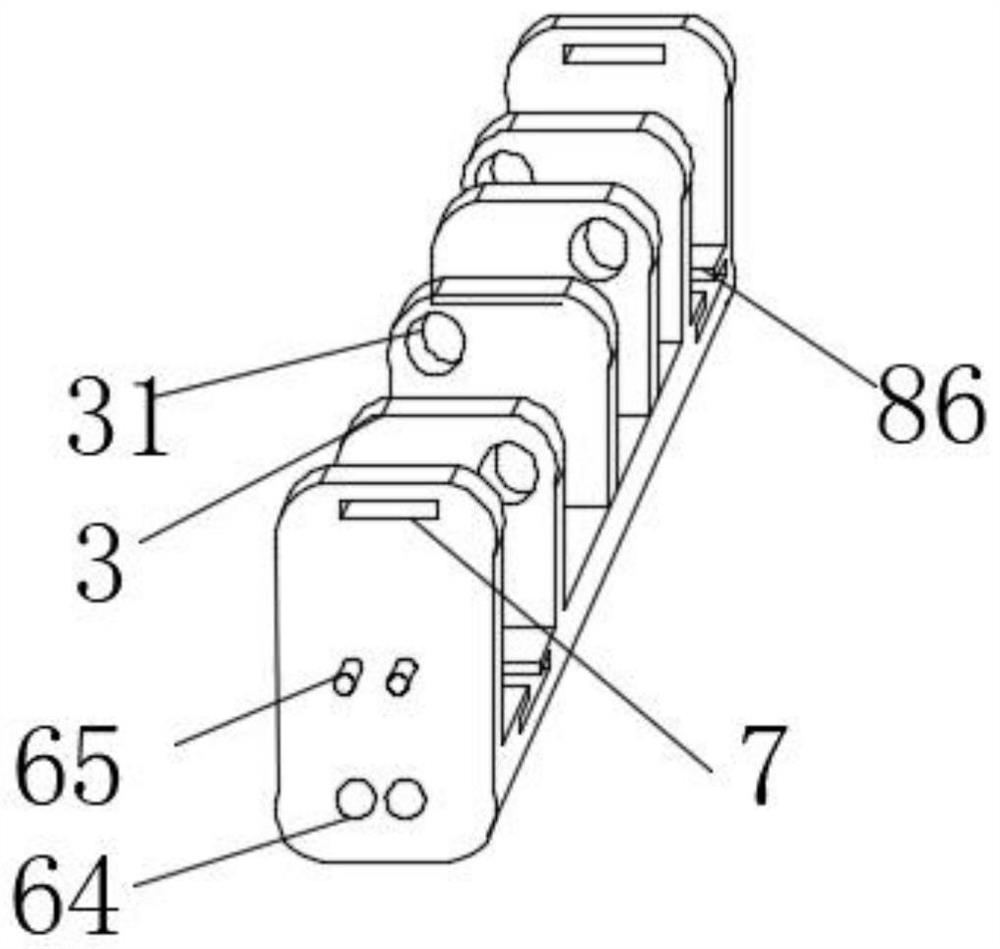

An anti-single ring lifting device

ActiveCN106968619BSingle hanging preventionImprove lifting safetyDrilling rodsDrilling casingsMarine engineeringOil drilling

The invention discloses a single-hoisting-ring hoisting prevention device and belongs to the technical field of oil drilling equipment. The single-hoisting-ring hoisting prevention device comprises stopping blocks arranged in lower slots of hoisting lugs, and is characterized in that the stopping blocks are fixed in the lower slots through first rotating shafts and provided with sensing components for monitoring the positions of hoisting rings, and trigger blocks are arranged on the inner walls of the lower slots; and the device further comprises a single-hoisting prevention component which comprises a controller, and the controller is connected with the sensing components in a radio mode and used for receiving signals sent by the sensing components to control starting and stopping of traveling blocks. The device can accurately judge whether hoisting rings on the two sides of a lift sub enter hoisting lug holes or not and then send commands for hoisting or non-hoisting, single-hoisting-ring hoisting can be effectively prevented, and hoisting safety is improved.

Owner:CHENGDU ZHUOXIN IND

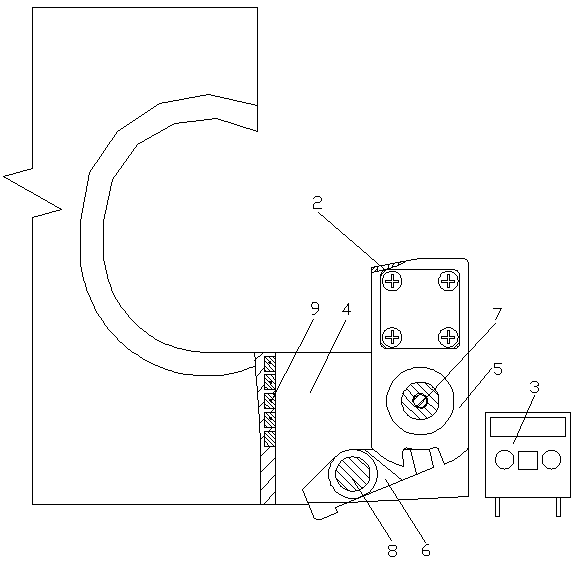

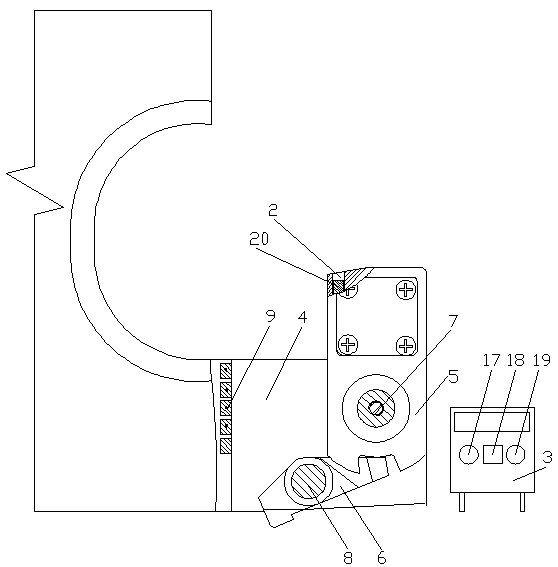

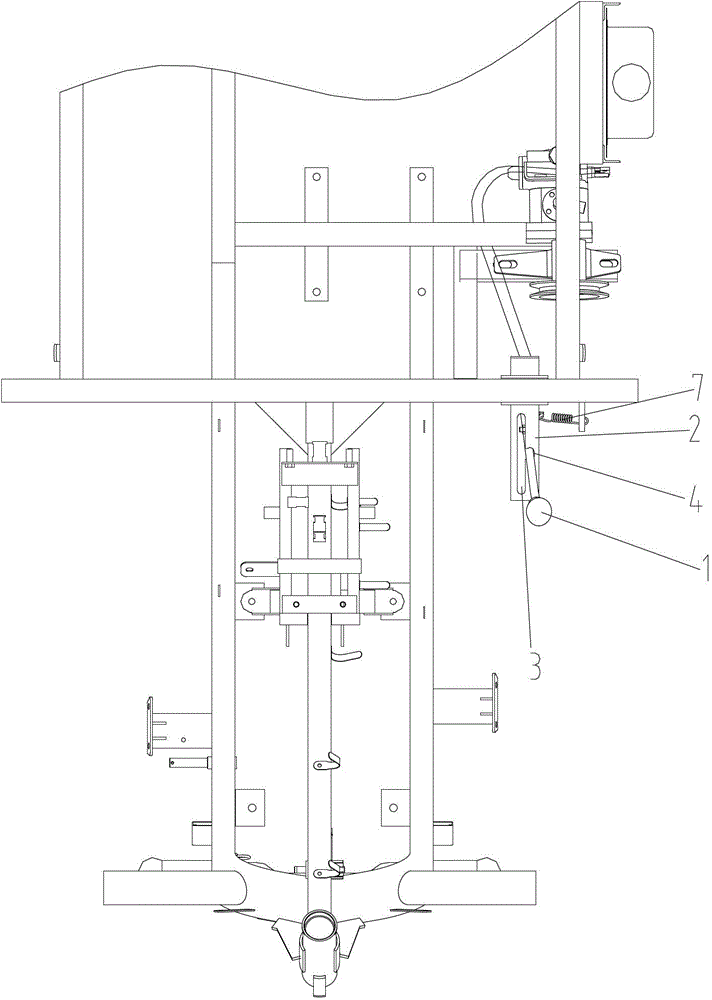

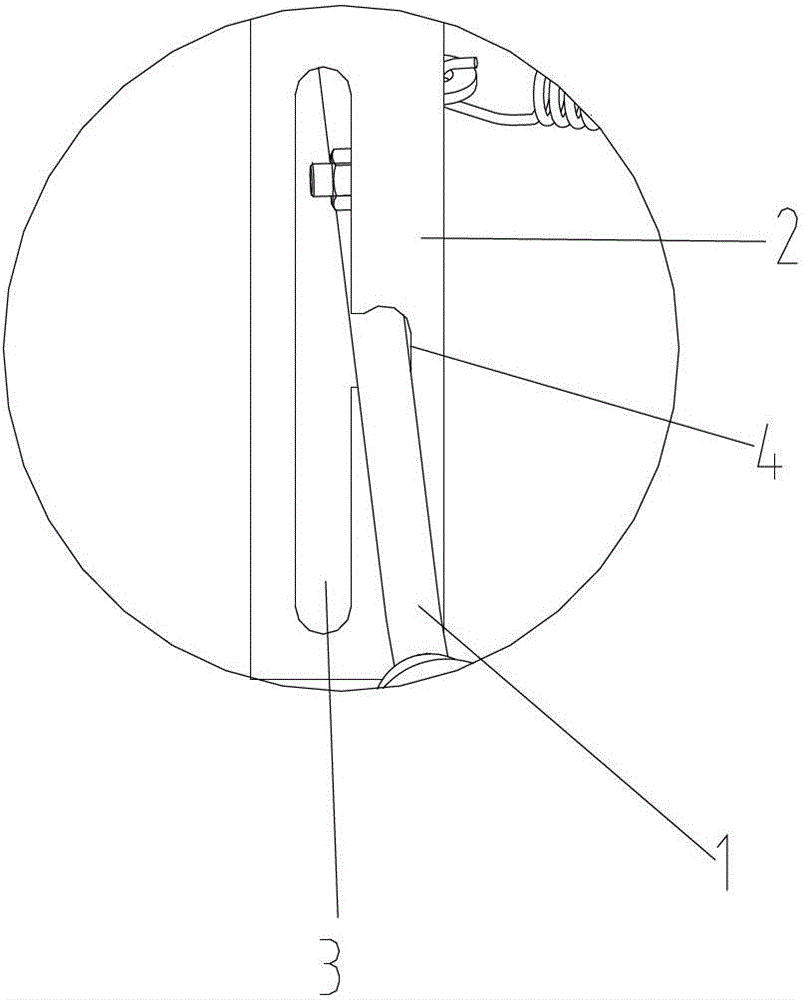

Safety protection device for manipulating the dump truck and its dump truck

ActiveCN103465820BEnsure lifting safetyAvoid sudden changesVehicle with tipping movementMachine controlControl engineering

The invention discloses a safety protection device for controlling a self-discharging vehicle carriage. The safety protection device comprises a carriage lifting control rod and a limiting mechanism matched with the control rod to limit the control rod in controlling carriage descending. The limiting mechanism is provided with a limiting part for controlling the control rod. Based on a self-discharging vehicle power part, to guarantee carriage lifting safety, an oil line hydraulic oil flow control structure is installed on an oil line generally; by limiting the power machine control rod, the oil line control structure can well serve the effect of preventing hydraulic oil from flowing, abrupt change of the carriage position is avoided, and use safety of a whole vehicle is enhanced; when the carriage is lifted or descended, operation on the control rod can be facilitated, the carriage can be lifted or descended according to the operation requirements, operation procedures and labor intensity of operators are reduced, and the safety protection device is flexible and convenient to operate and can perform safety protection on the carriage which is at a random overturning angle.

Owner:LONCIN MOTOR

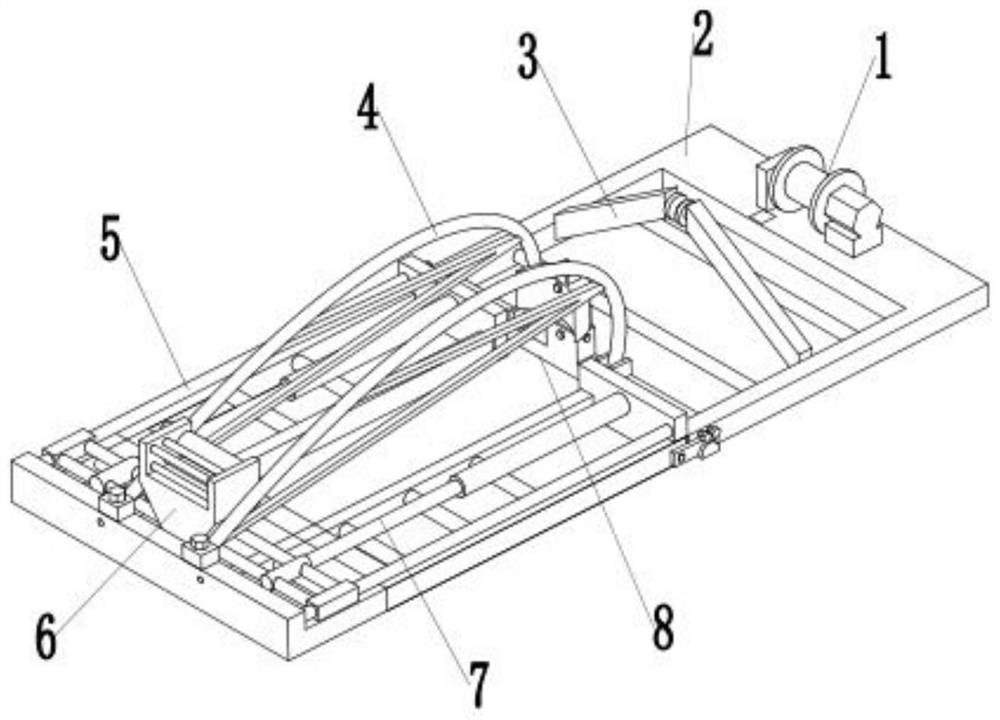

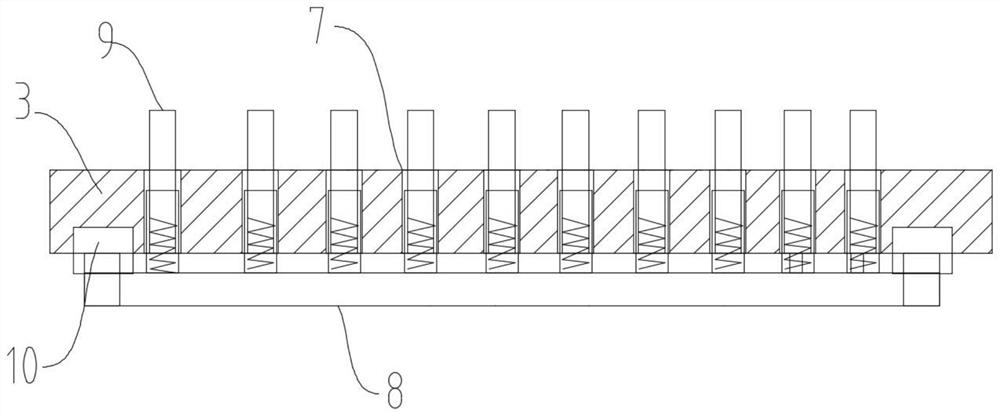

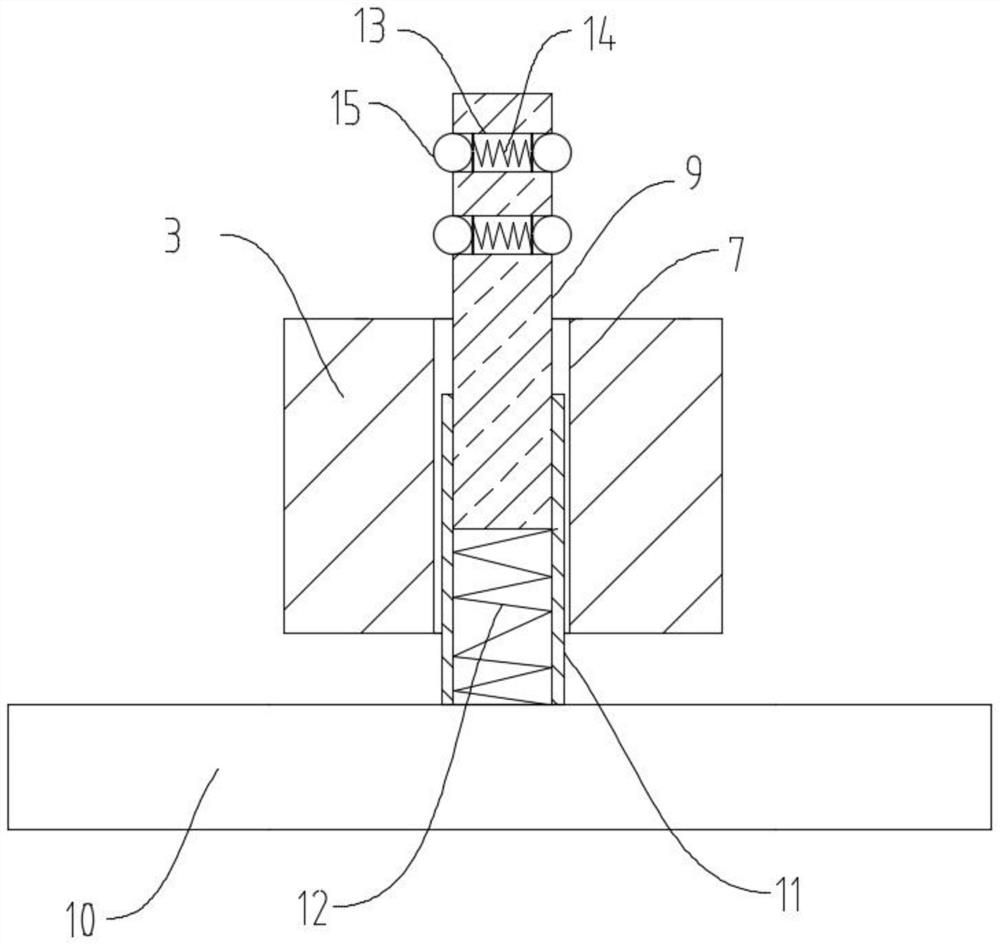

Tractor lifting operation platform

InactiveCN114671375AEffective limitSimple structureLifting framesAgricultural engineeringStructural engineering

The invention provides a tractor lifting operation platform and relates to the technical field of agricultural machinery, the tractor lifting operation platform comprises a base, a lifting net plate, a lifting rack, a lifting driving assembly and an adjustable fixing assembly, the lifting rack is fixedly arranged on the base, the lifting net plate is movably arranged on the lifting rack and used for bearing a tractor, and the lifting driving assembly is arranged on the lifting rack. The lifting driving assembly is arranged at the bottom of the base and is in transmission connection with the lifting net plate, a plurality of receding holes are formed in the lifting net plate in an array mode, and the adjustable fixing assembly is movably arranged at the bottom of the lifting net plate and selectively penetrates out of at least part of the receding holes so as to limit the tractor. Compared with the prior art, the tractor lifting operation platform is simple in structure and convenient to operate, meanwhile, due to the fact that the adjustable fixing assemblies are arranged to limit the front, back, left and right of the tractor, the tractor can be effectively limited in the lifting process, movement or toppling of the tractor is avoided, and lifting safety is guaranteed.

Owner:CHONGQING ACAD OF AGRI SCI

Construction Method of Long-span Downward Rigid Tied Steel Arch Bridge

InactiveCN107905116BLow requirements for construction site conditionsShort construction periodBridge erection/assemblyMain channelSpandrel

The invention discloses a construction method of a large-span through type rigid tied bar steel arch bridge. The steel arch bridge comprises a bridge superstructure, a bridge substructure and a bridgebearing. The construction method comprises the following steps that construction of the bridge substructure is conducted; sectional prefabrication of the bridge superstructure is conducted; integralassembling of the bridge superstructure is conducted; the bridge superstructure is overall hoisted through a floating crane; tugboats abreast tow the floating crane to sail in a main channel; the floating crane is subjected to load movement in a narrow river channel; and the bridge superstructure is overall mounted through position adjusting. According to the construction method, segmented-transporting of the bridge superstructure to a bridge site for overall assembling is not required, overall assembling of the overall assembling is completed in an overall assembling site of a wharf, and thenone floating crane is adopted to overall hoist the bridge superstructure to the bridge site for overall hoisting; and the scheme does not require building of a temporary support, the requirement of conditions of a construction site is low, impact on the surrounding environment is low, and the construction period is short.

Owner:CHINA SINOCONST HEAVY IND +1

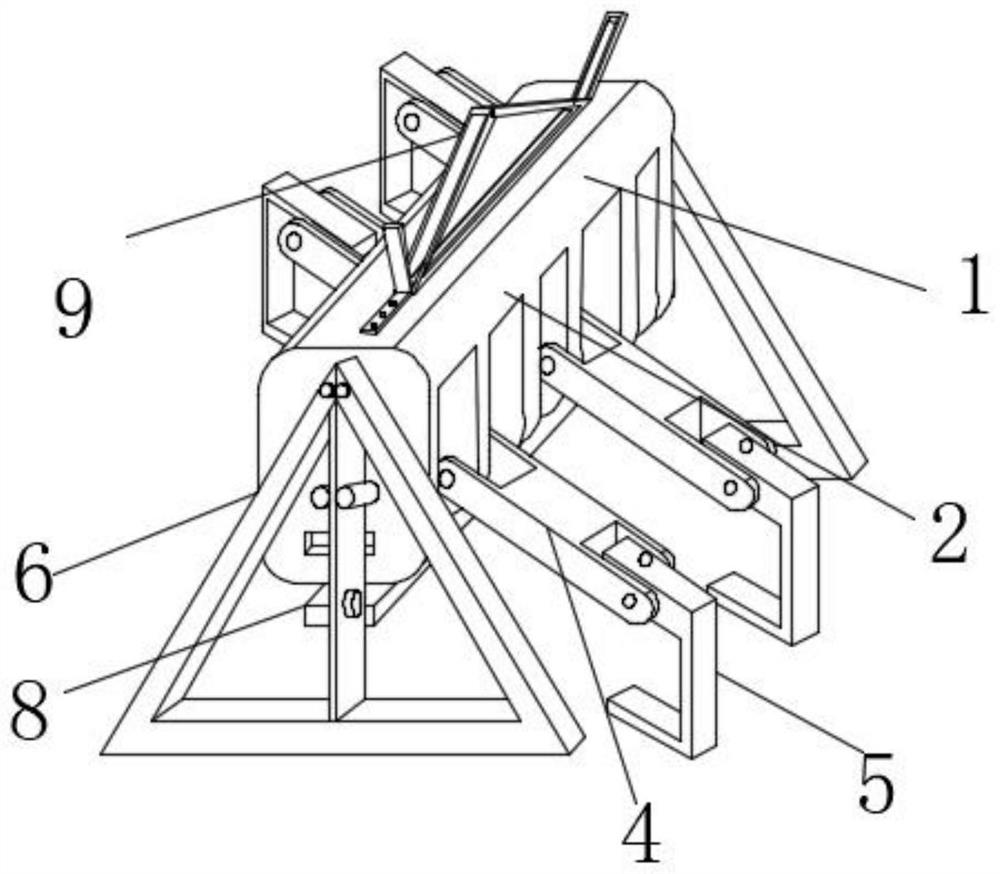

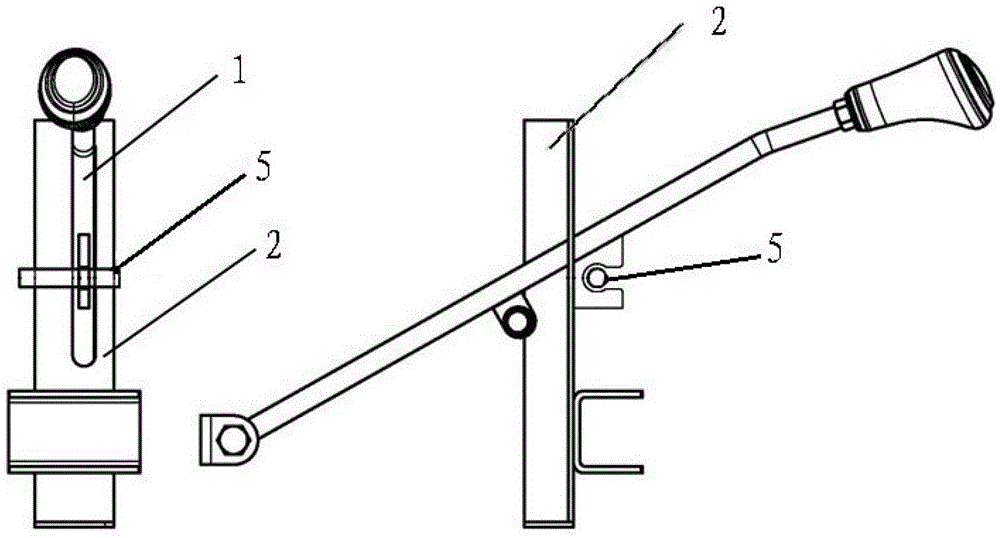

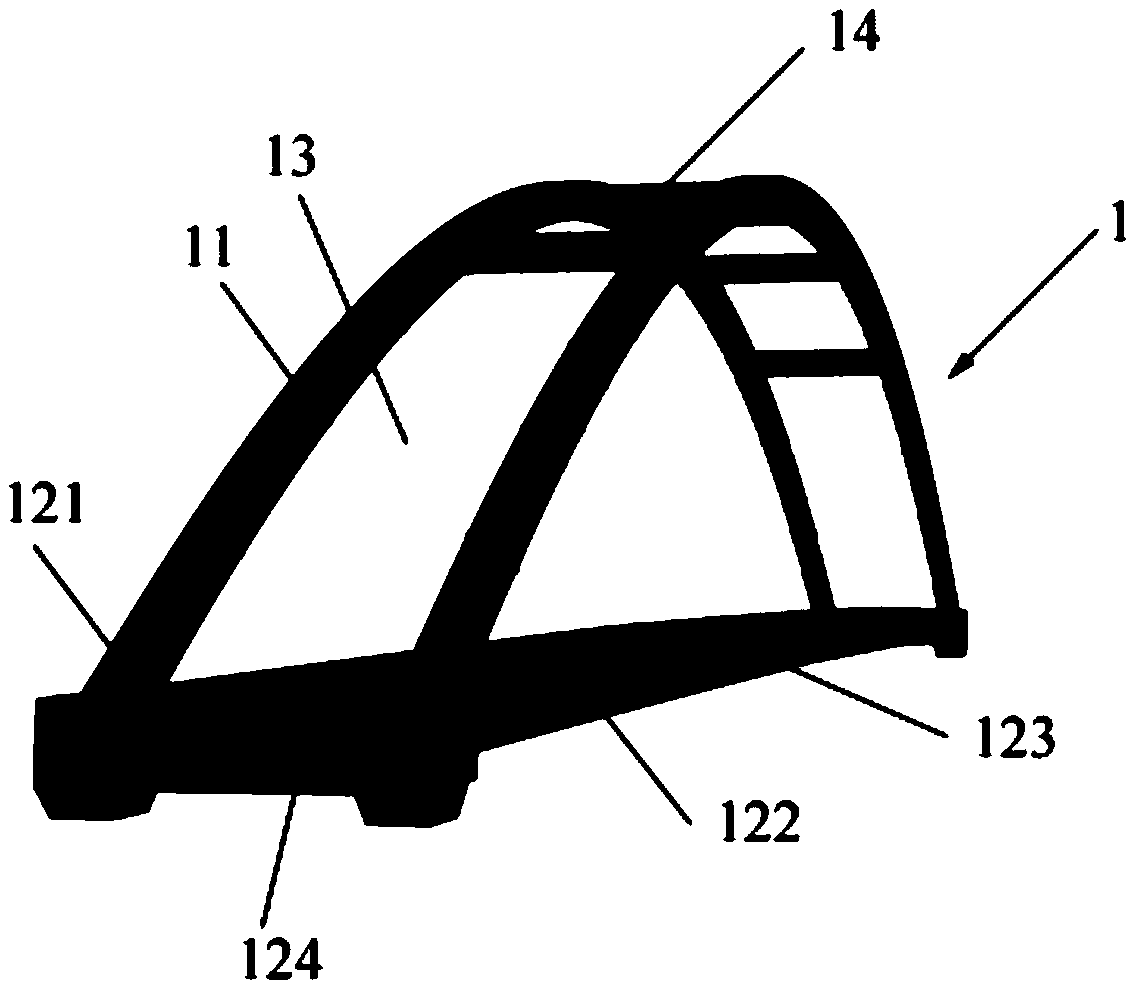

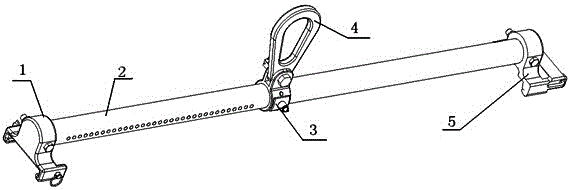

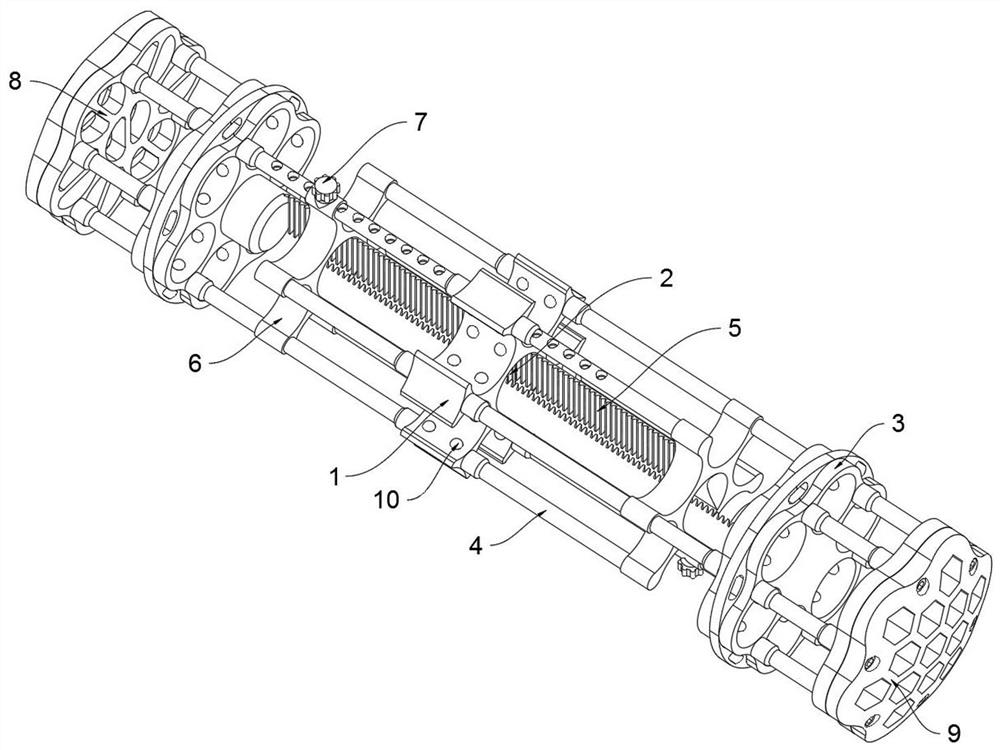

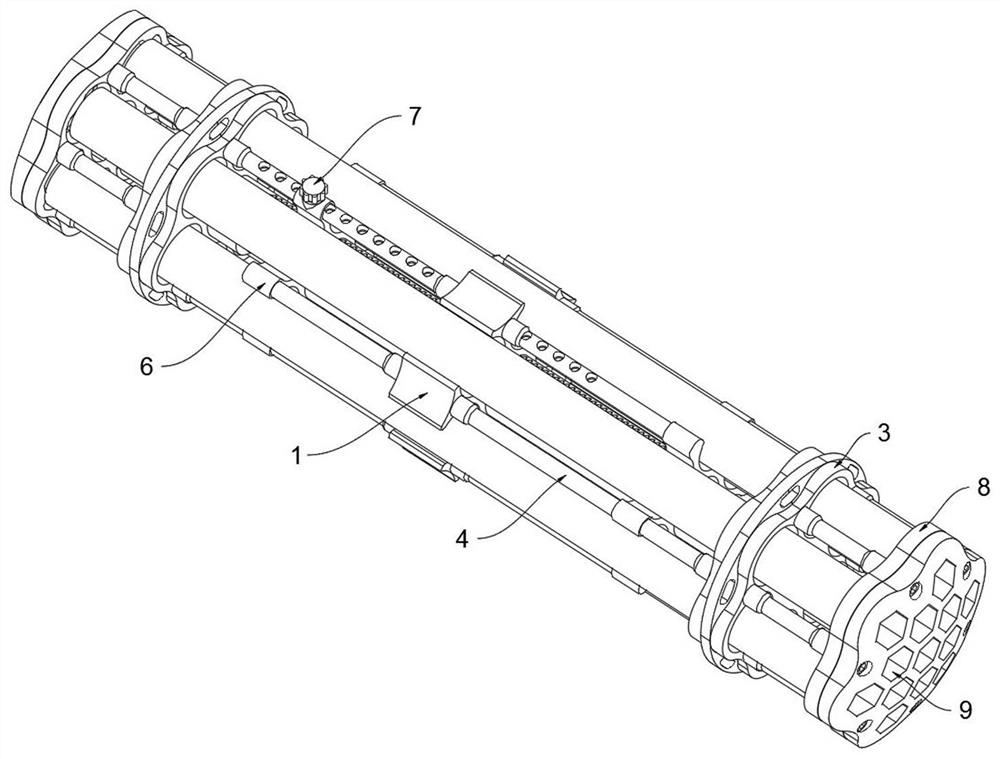

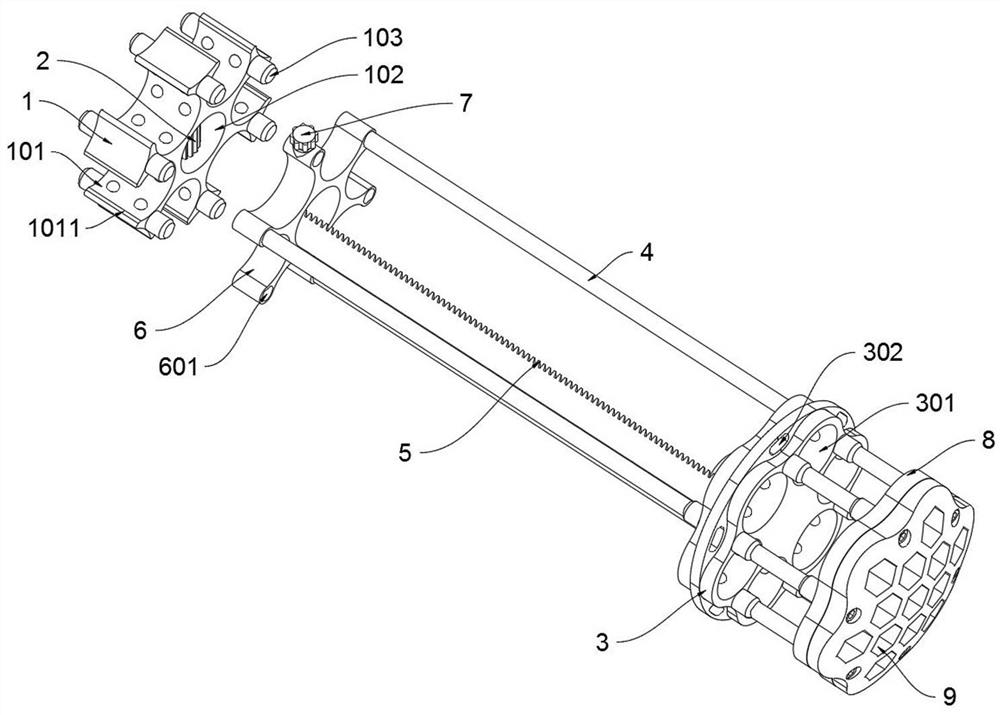

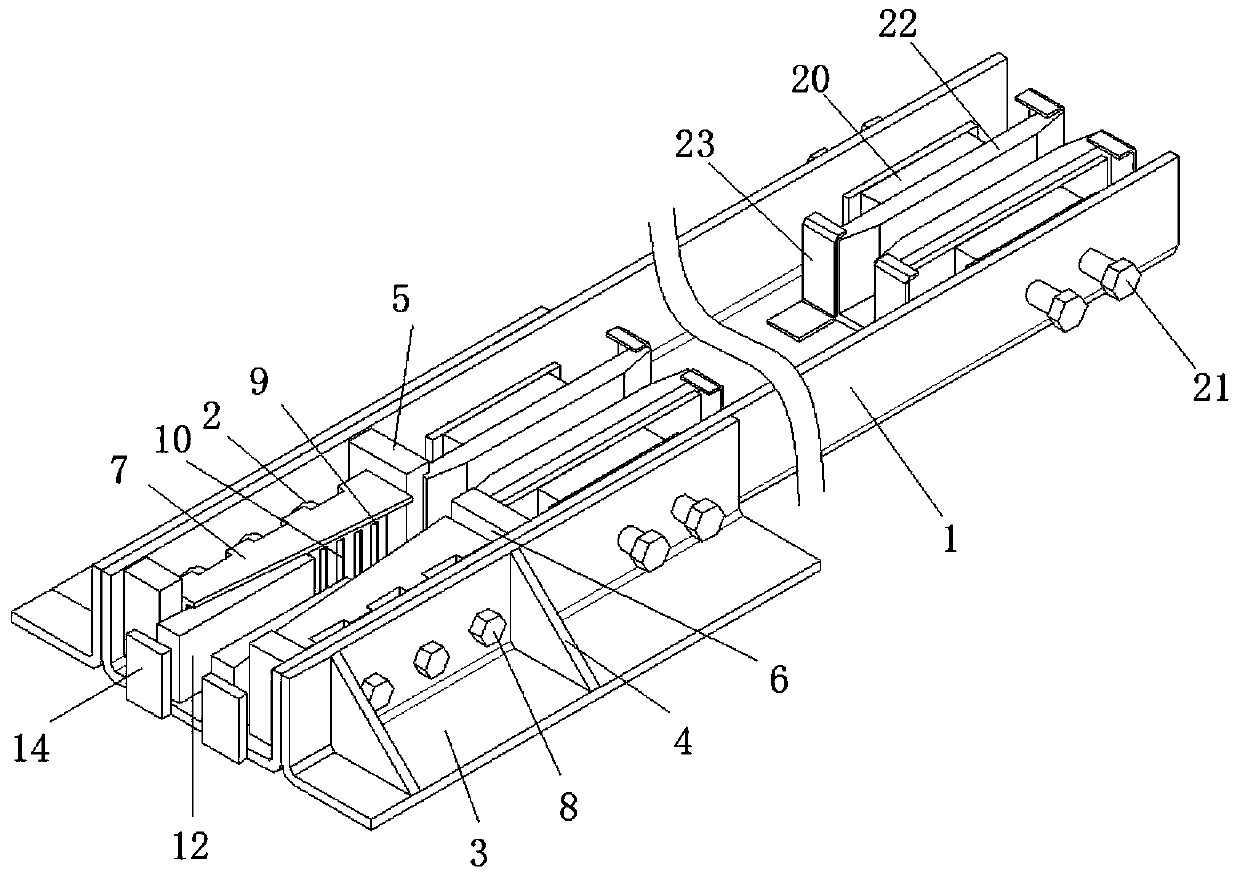

A missile spreader capable of quick adjustment and automatic locking

ActiveCN104401868BFast implementation of state adjustmentsEnsure lifting safetyLoad-engaging elementsMissileCenter of mass

The invention discloses a missile lifting appliance with a quick state regulation function and an automatic locking function. The missile lifting appliance comprises a lifting appliance girder, a positioning device, a lifting ring, a front lifting block and a rear safety device, wherein the positioning device is arranged below the lifting ring, and is used for fixing the lifting ring at a specific position of the lifting appliance girder; a plurality of positioning holes are formed in one side of the lifting appliance girder and respectively correspond to the centre-of-gravity positions of missiles of different types; the front lifting block and the rear safety device are respectively arranged at two ends of the lifting appliance girder. The missile lifting appliance is easy to operate and high in lifting safety, and has the advantage that quick regulation is realized.

Owner:JIANGXI HONGDU AVIATION IND GRP

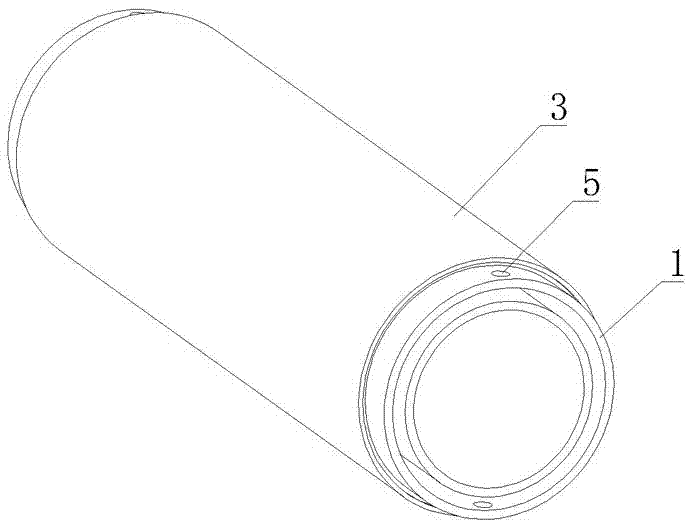

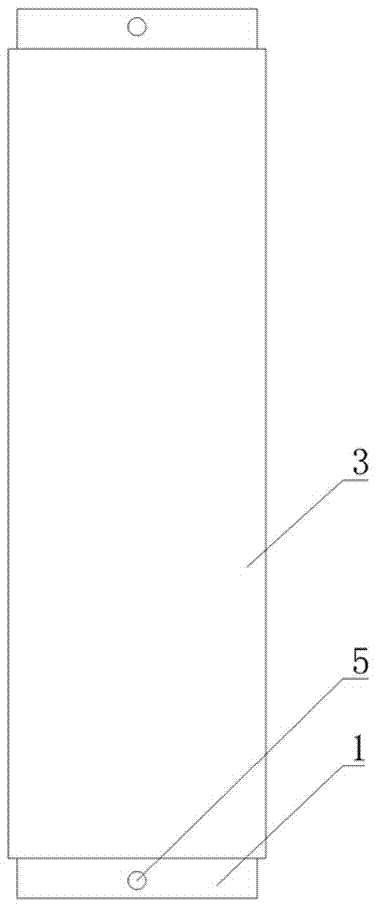

Thermal-insulation prefabricated direct-buried pipe

InactiveCN106895215AImprove securitySimple structureThermal insulationPipe protection by thermal insulationThermal insulationEngineering

The invention discloses a heat-preserving prefabricated direct-buried pipe, relates to a composite pipe, and is used for solving the problem that the existing direct-buried pipe is easy to fall off when installed by a crane. It includes a prefabricated concrete layer, an insulation layer and a protective layer arranged sequentially from the inside to the outside, the edges of both ends of the precast concrete layer leak out of the protective layer, the precast concrete layer is composed of an inner layer and an outer layer, the inner layer and The outer layers are separated from each other to form cavities, the inner layer and the outer layer are fixed by connecting pieces, and openings are arranged at both ends of the outer layer. By setting the composite layer, it can not only ensure the tightness of the inner layer, but also ensure the safety of lifting.

Owner:潼南县梓潼镇大桥预制厂

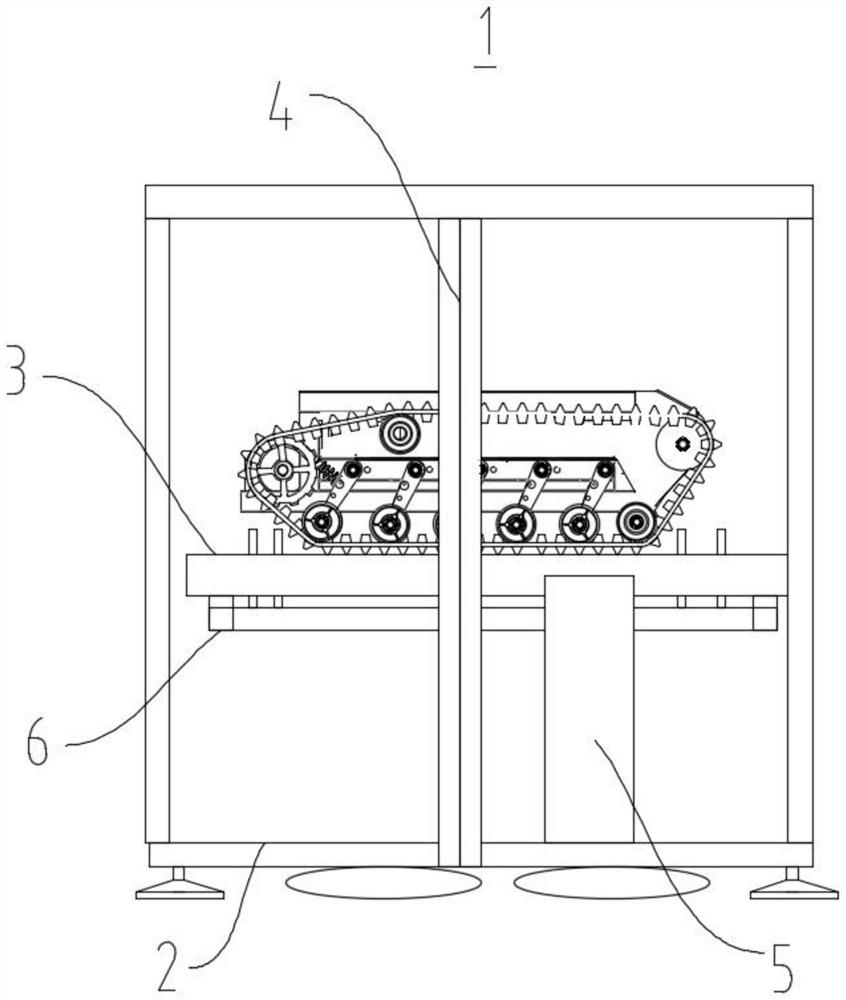

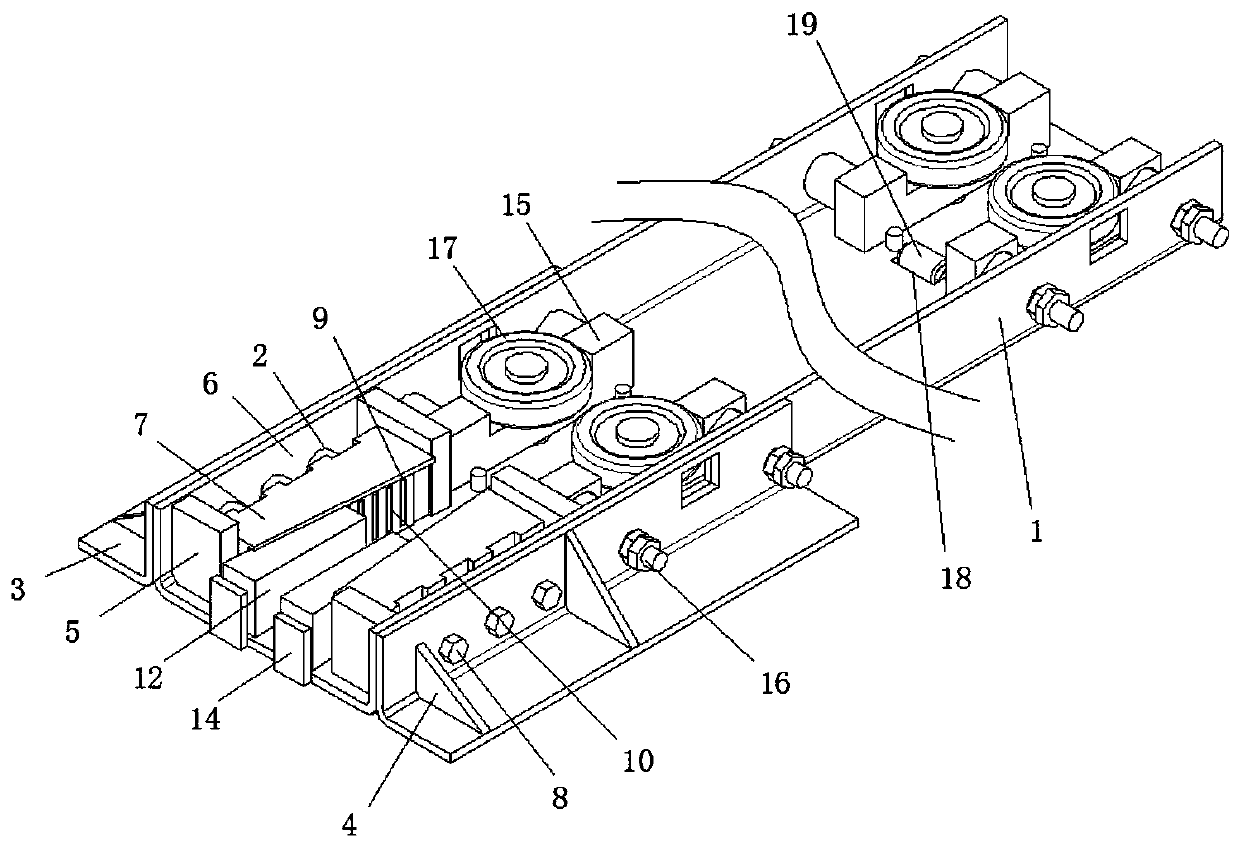

A lifting limit device of double protective pipes for construction lifting machinery

ActiveCN113548577BLoading and unloadingPlay a clamping and fixing effectNon-rotating vibration suppressionLoad-engaging elementsPipe fittingGear wheel

The invention provides a double-protection pipe hoisting limit device for construction hoisting machinery, relates to the technical field of pipe hoisting, and includes a main assembly and an auxiliary assembly; a synchronous gear is installed inside the main assembly, and the main The mounting parts are respectively connected with the auxiliary mounting parts and the movable auxiliary frame through sliding rods; the peripheral of the auxiliary mounting parts is circular, and the peripheral of the auxiliary mounting parts is surrounded by six hoisting holes, and the flexible buffer block is connected with the side baffles The auxiliary parts are connected; the gear rod is connected to the inside of the main part, and the auxiliary part is connected to the movable auxiliary frame through the gear rod; the center part of the movable auxiliary frame is hollow, and the external part of the movable auxiliary frame is connected to the manual bolt; In the present invention, after the pipe fittings are respectively placed in the storage holes inside the main fitting through the loading and unloading openings, the left and right ends of the pipe fittings are respectively inserted into the limit inner holes set by the auxiliary fittings at both ends, and the two ends of the pipe fittings are connected by the auxiliary fittings The end is limited to prevent the pipe fittings from falling out of the loading and unloading port during hoisting, causing damage to the ground construction personnel, and making the pipe fittings loading and unloading more convenient.

Owner:南通铭朗建筑机械有限公司

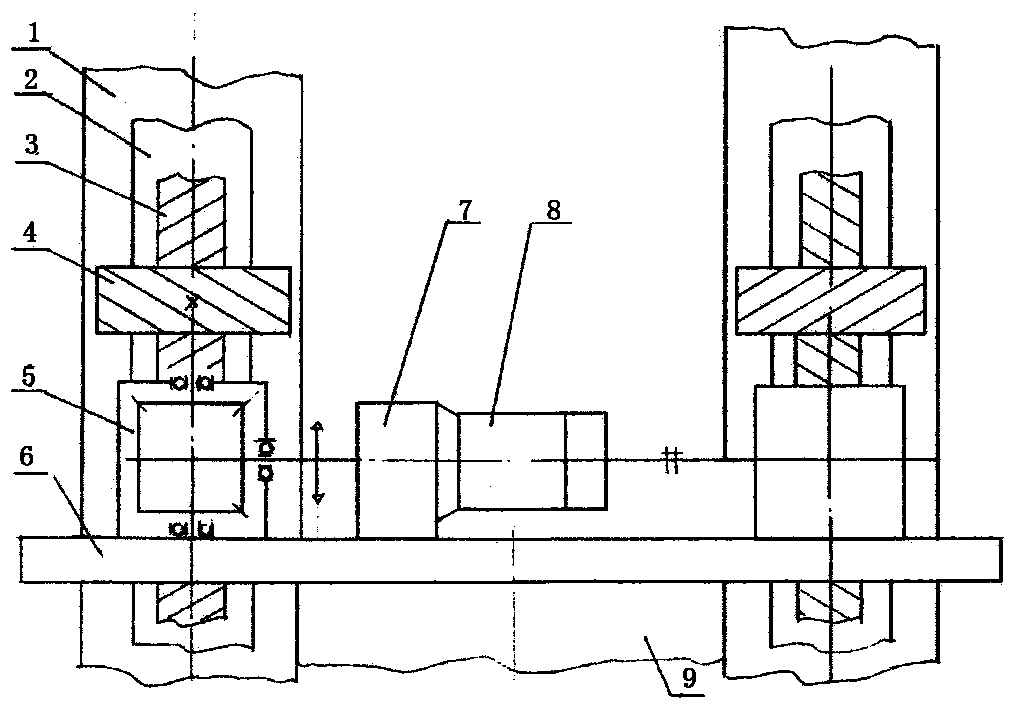

Novel straight beam integration module

PendingCN111170116ASave installation spaceImprove effective protectionElevatorsStructural engineeringMechanical engineering

The invention belongs to the technical field of elevators, and particularly relates to a novel straight beam integration module. A beam body, a braking mechanism and a guiding mechanism are included.Strengthening ribs and strengthening plates are arranged at one end position of the beam body. The braking mechanism is symmetrically provided with guiding wedge blocks, and the guiding wedge blocks are located between the strengthening plates. The guiding mechanism comprises a first fixing base, and the first fixing base conducts positioning guiding through a cylinder bolt. According to the novelstraight beam integration module, through the arrangement of the braking mechanism, the effect of guaranteeing elevator lifting safety is achieved, meanwhile, the braking mechanism is integrally arranged in the beam body, accordingly, the installing space is reduced, and meanwhile the strengthening ribs and the strengthening plates on the beam body can enhance effective protection on the brakingmechanism. Through the arrangement of the guiding mechanism, the braking mechanism can be buckled to a guide rail of an elevator shaft, the braking mechanism does not slide out of the guide rail of the elevator shaft, safety is improved, normal usage of the braking mechanism is guaranteed, meanwhile, the occupied space is small, and the braking mechanism is arranged in the beam body and can be protected.

Owner:杭州宝宸科技有限公司

Single-hoisting-ring hoisting prevention device

ActiveCN106968619ASingle hanging preventionImprove lifting safetyDrilling rodsDrilling casingsOil drillingEngineering

The invention discloses a single-hoisting-ring hoisting prevention device and belongs to the technical field of oil drilling equipment. The single-hoisting-ring hoisting prevention device comprises stopping blocks arranged in lower slots of hoisting lugs, and is characterized in that the stopping blocks are fixed in the lower slots through first rotating shafts and provided with sensing components for monitoring the positions of hoisting rings, and trigger blocks are arranged on the inner walls of the lower slots; and the device further comprises a single-hoisting prevention component which comprises a controller, and the controller is connected with the sensing components in a radio mode and used for receiving signals sent by the sensing components to control starting and stopping of traveling blocks. The device can accurately judge whether hoisting rings on the two sides of a lift sub enter hoisting lug holes or not and then send commands for hoisting or non-hoisting, single-hoisting-ring hoisting can be effectively prevented, and hoisting safety is improved.

Owner:CHENGDU ZHUOXIN IND

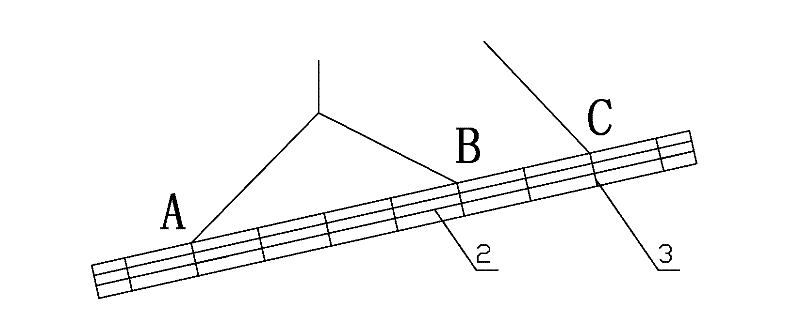

Suspension apparatus of ship main engine

The invention relates to a suspension apparatus of a ship main engine. The suspension apparatus comprises wire ropes, and further comprises a suspension frame. A left end on the top of the suspension frame is connected with a first traction part through a first wire rope (111). A right end on the top of the suspension frame is connected with a second traction part through a second wire rope (211). A left end on the bottom of the suspension frame extends to a first suspension point (A) of a main engine (5) through a third wire rope (112). A right end on the bottom of the suspension frame extends to a fourth suspension point (D) of the main engine (5) through a fourth wire rope (212). A middle portion of the suspension frame is provided with space, wherein a middle wire rope passes through the middle portion of the suspension frame from top to bottom, and extends to a corresponding second suspension point (B) and a corresponding third suspension point (C) in the space. An upper end of the middle wire rope is connected with a third traction part. Compared to the prior art, the apparatus provided by the present invention has the following advantages that: the structure of the apparatus is simple; the pulley block is not required; the apparatus is easy to be used; the production cost of the apparatus is low; the suspension beam structure of the apparatus is solid and stable so as to provide longer service life.

Owner:ZHEJIANG ZHENGHE SHIPBUILDING

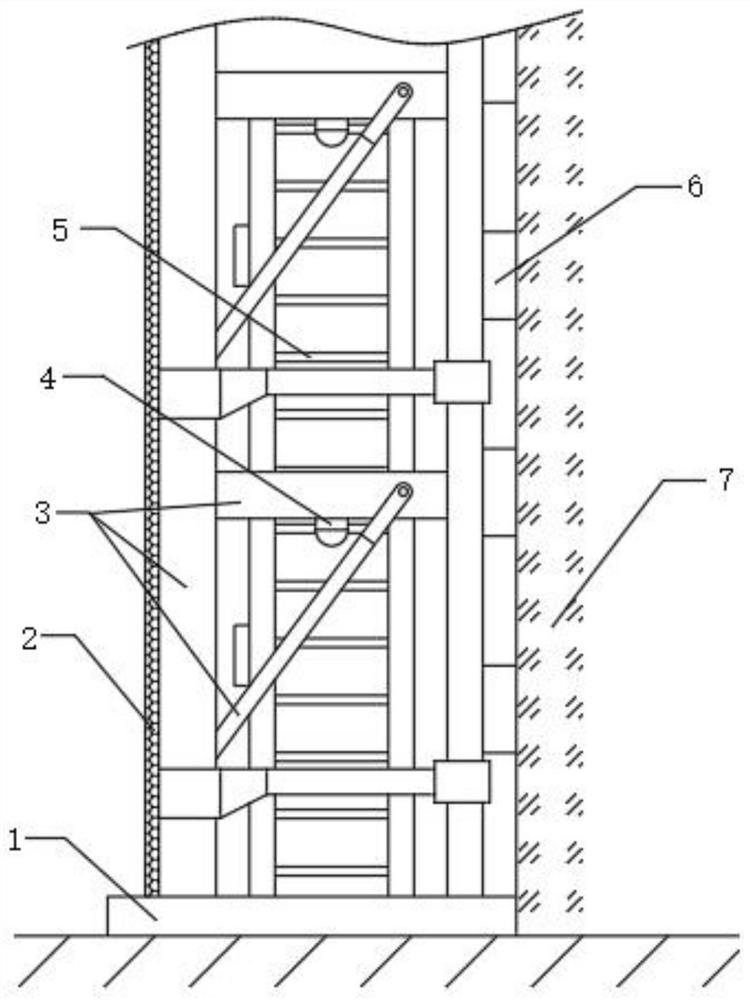

Attached lifting scaffold for high-rise building

InactiveCN114033148AAvoid unclearTimely detection of obstacles encountered in liftingMachines/enginesCleaning using toolsSurveillance cameraStructural engineering

The invention discloses a high-rise building attached lifting scaffold. The attached lifting scaffold comprises a high-rise building, wherein a supporting base is arranged on one side of the high-rise building, a mounting frame is arranged on an outer wall of the top of the supporting base, a protective net is arranged on one side of the mounting frame, a plurality of attachment mechanisms are arranged between the mounting frame and the high-rise building, and a crawling ladder is arranged in the mounting frame; and a plurality of monitoring cameras are arranged in the mounting frame, a protective cover, a controller, a servo motor and a storage battery are arranged on an outer wall of the bottom of each monitoring camera, and the controller, the servo motor and the storage battery are electrically connected. The attached lifting scaffold is advantaged in that the protective cover below the monitoring camera can be cleaned, dedusted or demisted, the situation that dust, impurities, water mist and the like are accumulated on the protective cover, and consequently pictures shot by the monitoring camera are not clear is avoided, and therefore the visual conditions that the lifting scaffold encounters a barrier in lifting, machine tool faults and the like can be found in time, and safety of constructors and lifting safety of the scaffold body are guaranteed.

Owner:方开华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com