High-molecular-weight polyethylene hoisting rope

A high-molecular-weight, polyethylene technology, applied in transportation and packaging, load-hanging components, braids, etc., can solve problems such as short service life of hoisting ropes, single strand breakage, safety accidents, etc., and achieve wear resistance and tensile strength Strong, guaranteed safety, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

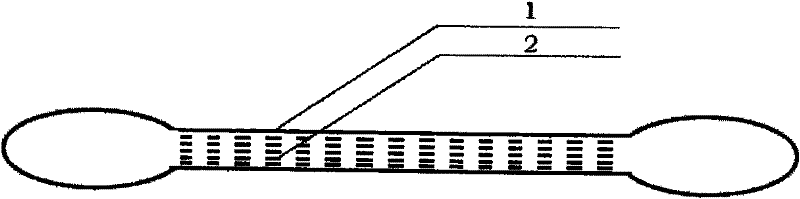

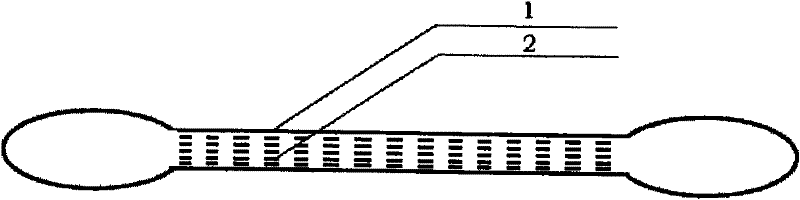

[0008] exist figure 1 Among them, the present invention is a high molecular weight polyethylene hoisting rope, which includes a high molecular weight polyethylene hoisting rope main body 2, the high molecular weight polyethylene hoisting rope main body 2 is braided by a number of high molecular weight polyethylene monofilaments, in the high molecular weight polyethylene The surface of the main body 2 of the polyethylene hoisting rope is provided with a resin layer 1, and the resin layer 1 adopts LAGO45 resin. Each 1T high molecular weight polyethylene hoisting rope uses high molecular weight polyethylene monofilament 120 filaments equal to 0.07kg, which saves 70% compared with ordinary types (polyester, nylon yarn); the component is resin; the proportion of high molecular weight polyethylene hoisting rope per 100m is 0.5 kg resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com