Transformer pulling board

A technology for transformers and pulling plates, which is applied to transformer/inductor parts, transformer/inductor coils/windings/connections, electrical components, etc. effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

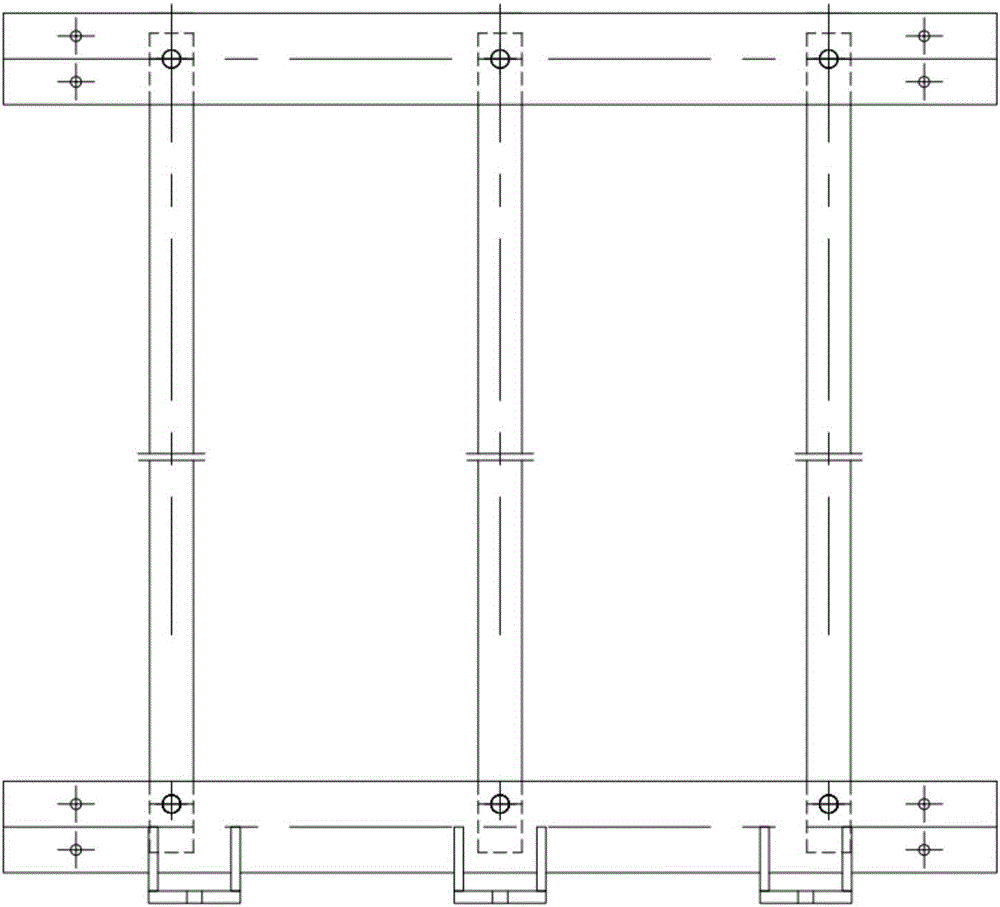

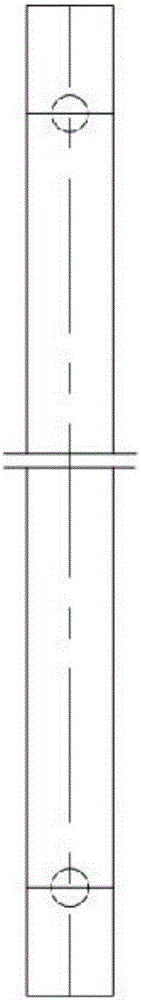

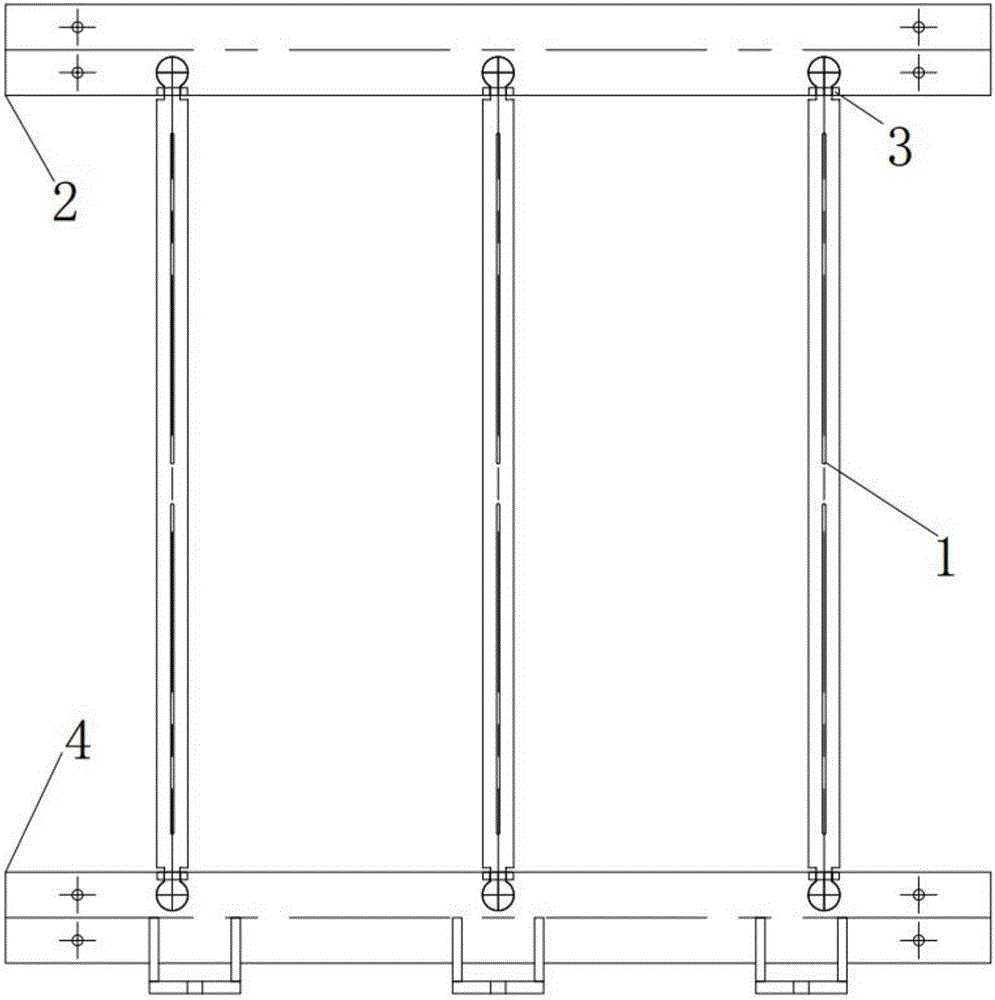

[0019] Such as Figure 3-5 Shown, a kind of transformer drawing board comprises drawing board (1), is divided into the clamping part of upper clamping part (2), lower clamping part (5) and the support plate (5) on the upper and lower clamping parts; ) are in the shape of an arc, and at the same time, the ends of the arc grooves of the upper clamp (2) and the lower clamp (4) are processed to match the corresponding size of the end of the pull plate, which can be embedded in the arc shape The upper clamp (2) and the lower clamp (4) cooperate with the pull plate (1), the pull plate (1) can be buckled with the upper and lower clamps, and the mating surface is flush, and the mating surface can bear The weight of the body during lifting; the support plate (3) welded to the end of the arc groove on the upper and lower clamps is used to prevent the outward arching deformation of the pull plate in the length direction and the displacement in the front and rear directions when the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com