Hinged lifting appliance

A hinged and spreader technology, which is applied in the field of spreaders, can solve problems such as obstacles to the operation of embedded bolt connections, inability to use electric tools, and inconvenient operation of manual tools, and achieve the effects of easy manufacture, simple structure, and safe lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

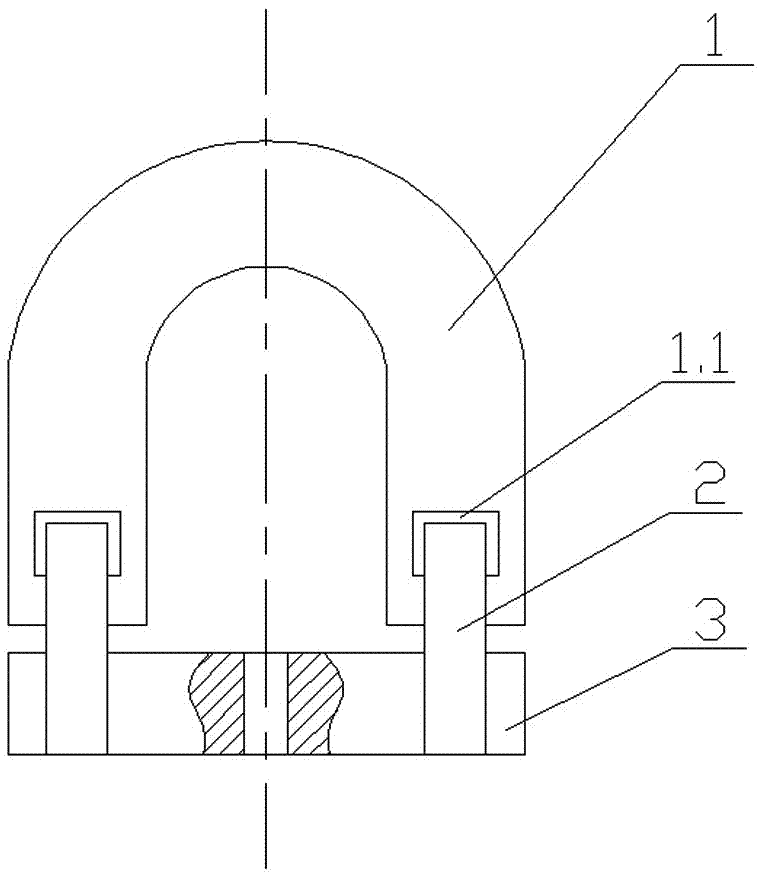

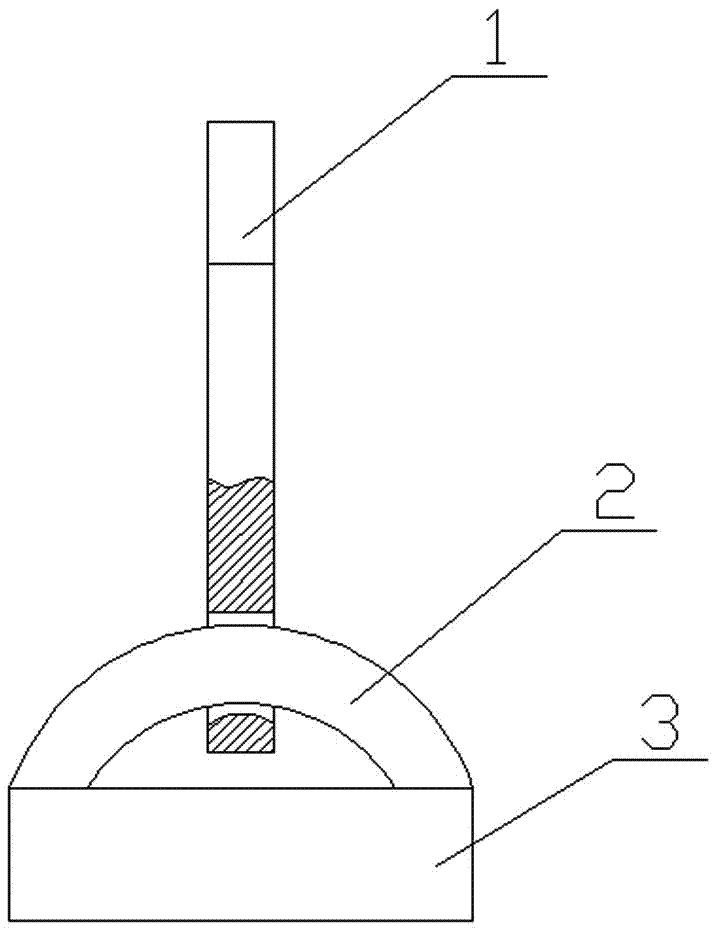

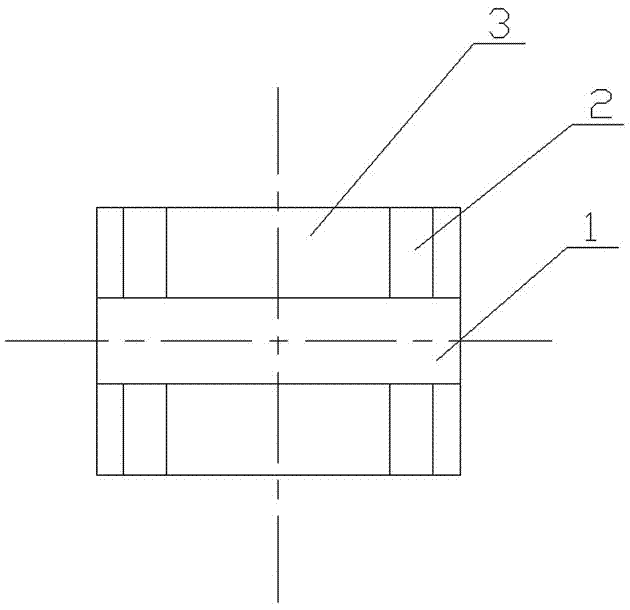

[0017] The hinged spreader shown in the accompanying drawing is composed of a hanger 1, a ring 2 and a bottom plate 3. The hanging buckle 1 is a member used to tie the lifting wire rope. The inverted U-shaped hanging buckle 2 is made of steel plate. At the same position at both ends of the opening side, there are respectively horizontal rectangular through-holes 1.1. The rectangular through-holes 1.1 are connected by chains. One of the basic components. In order to further improve the flexibility of the chain connection, the cross-section of the bottom edge of the rectangular through hole 1.1 in this embodiment is arc-shaped, and the specific shape is shown in figure 2 . The buckle 2 is a semicircular steel fastener with a rectangular cross section. The bottom plate is a rectangular steel plate, the two ends of the long side walls a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com