Special lifting appliance of side wall of coal conveying open wagon

A spreader and car side technology, which is applied in the field of special spreader for the side wall of coal transport gondola car, to achieve the effect of reducing labor intensity, compact structure and shortening production cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but it should not be understood that the scope of the above subject of the present invention is limited to the following embodiments.

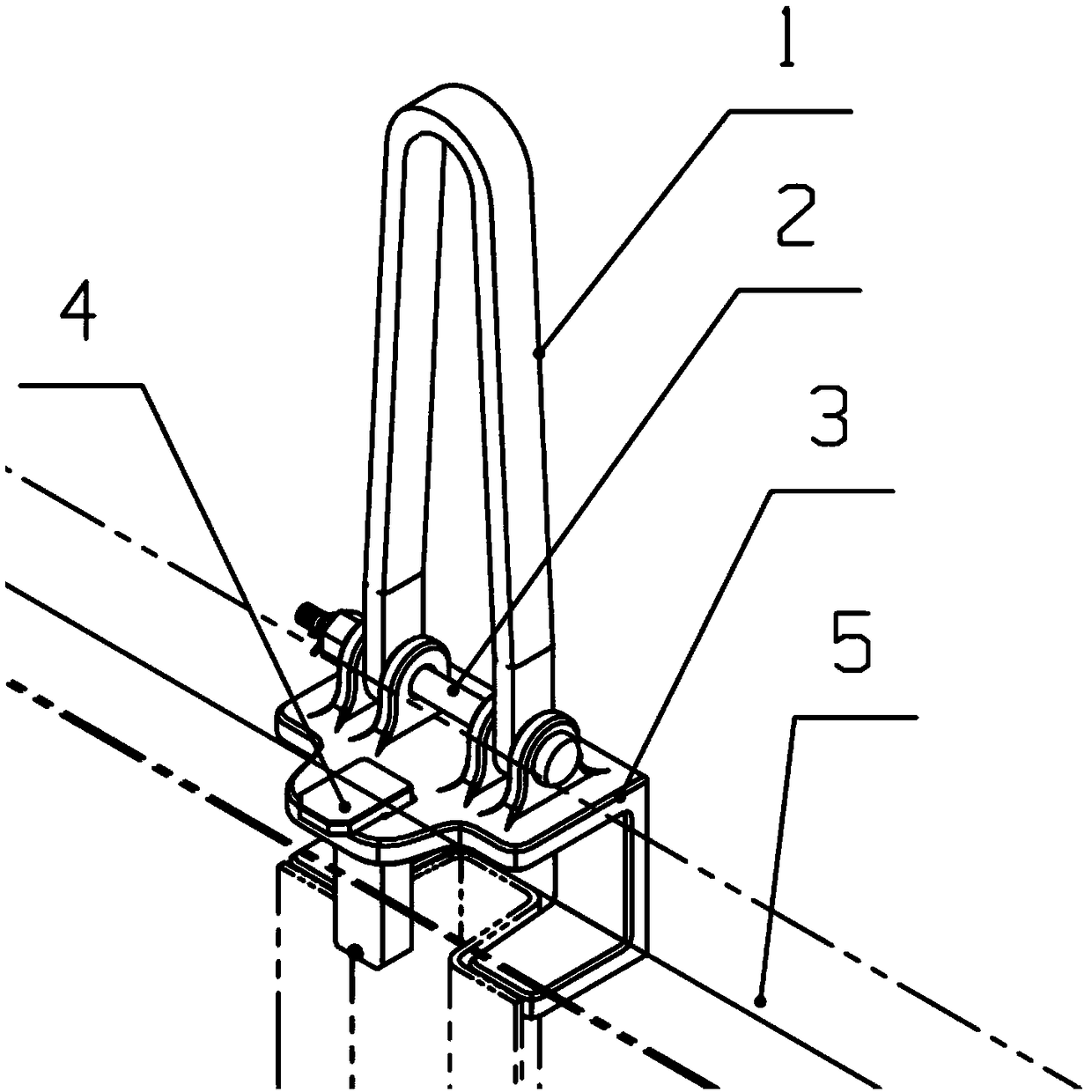

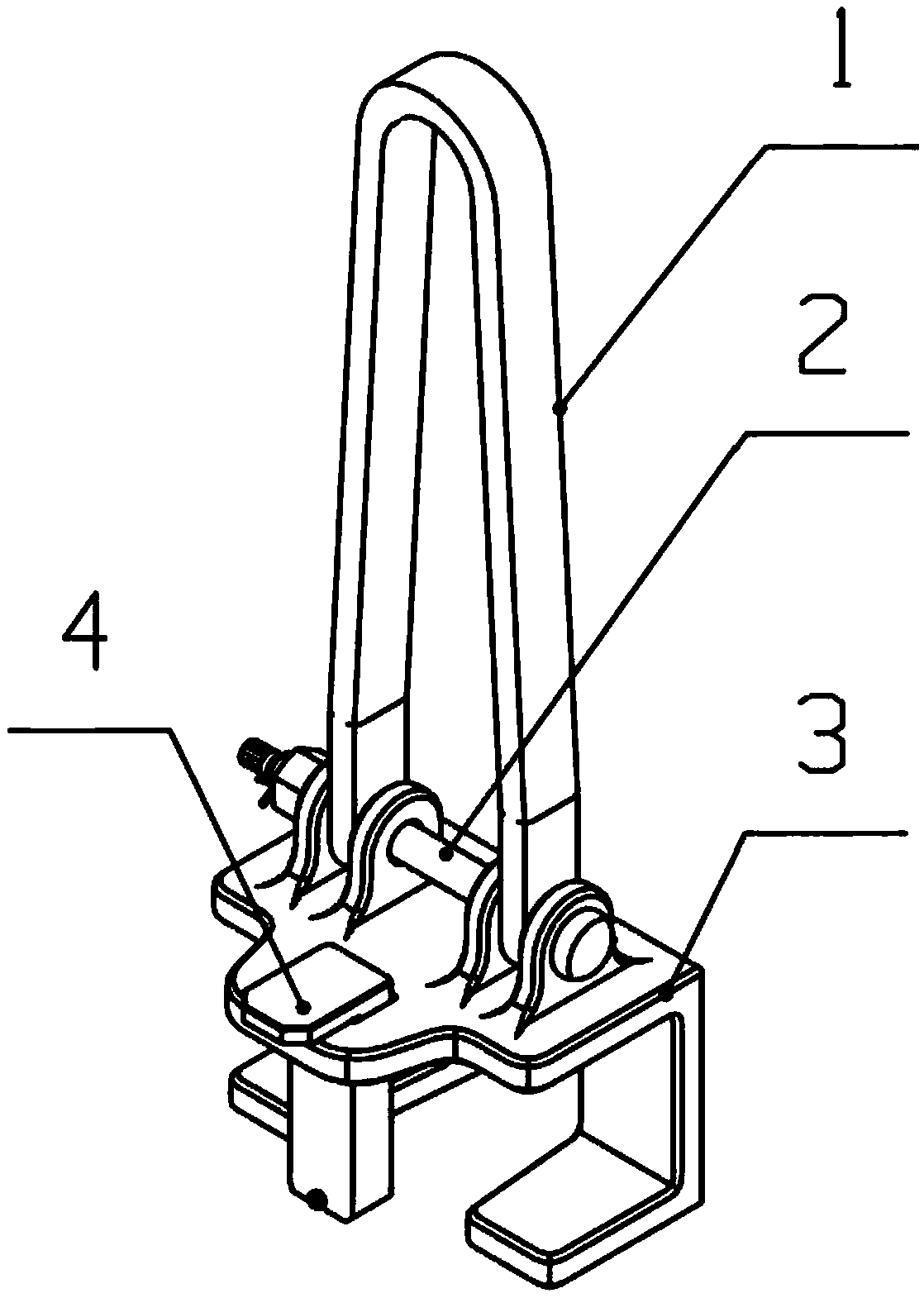

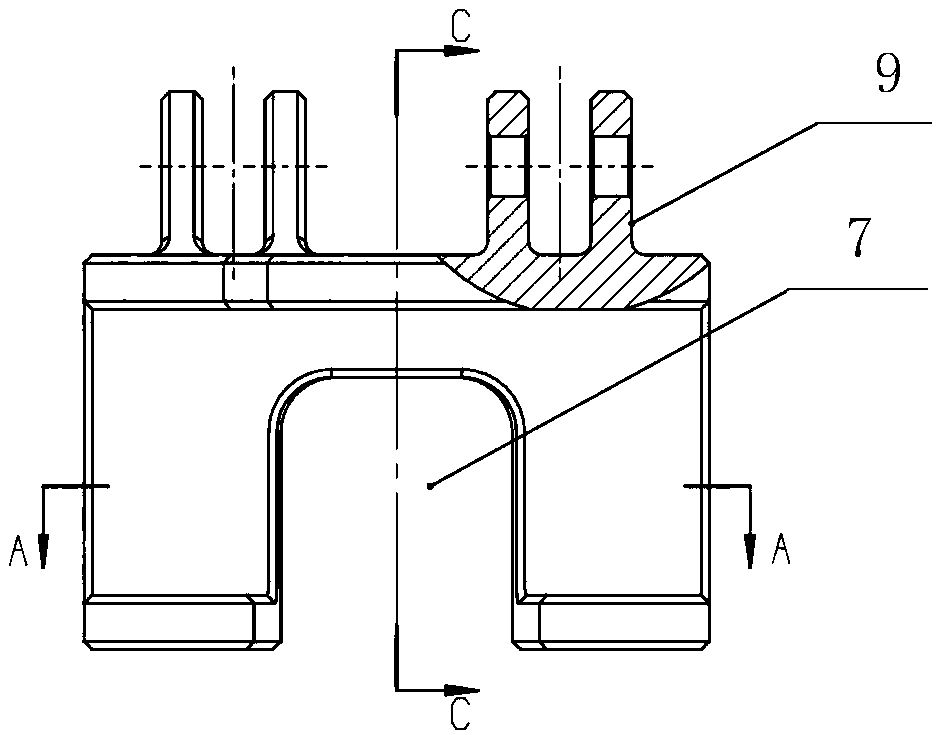

[0030] refer to Figure 1-Figure 10 , the present invention provides a special spreader for the side wall of a coal-transporting gondola car. The special spreader includes a double-buckle flexible sling 1, a high-strength bolt connection pair 2, a card-loading groove body 3 and a catch 4; the double-buckle flexible sling 1 passes through the high The high-strength bolt connection pair 2 is connected with the card slot body 3; the high-strength bolt connection pair 2 includes a screw and a nut; the double-buckle flexible sling 1 can lift a weight of 3T, and the open end of the double-buckle flexible sling 1 is provided with a high-strength bolt connection. The through hole matched with the screw rod of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com