Square pile vacuum suction disk bridge type crane

A technology of bridge cranes and vacuum suction cups, which is applied in the direction of cranes, trolley cranes, and traveling mechanisms. Efficiency, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

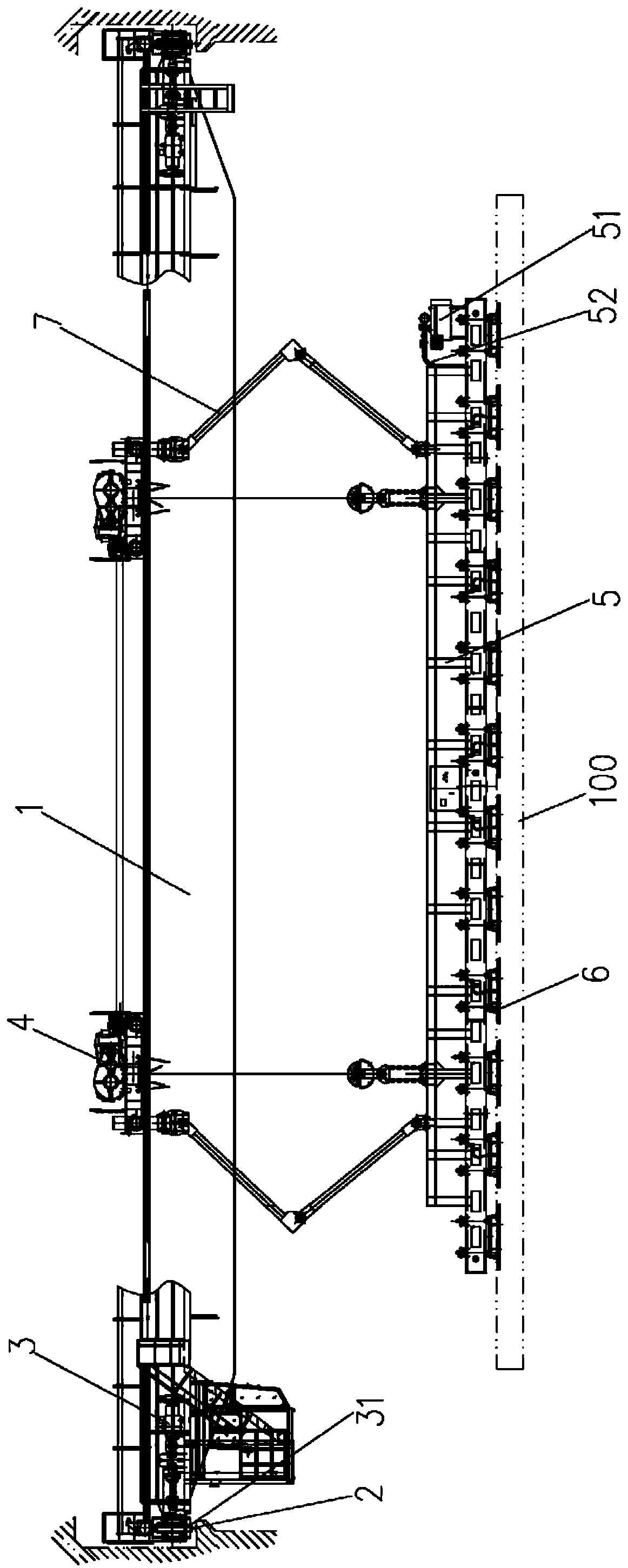

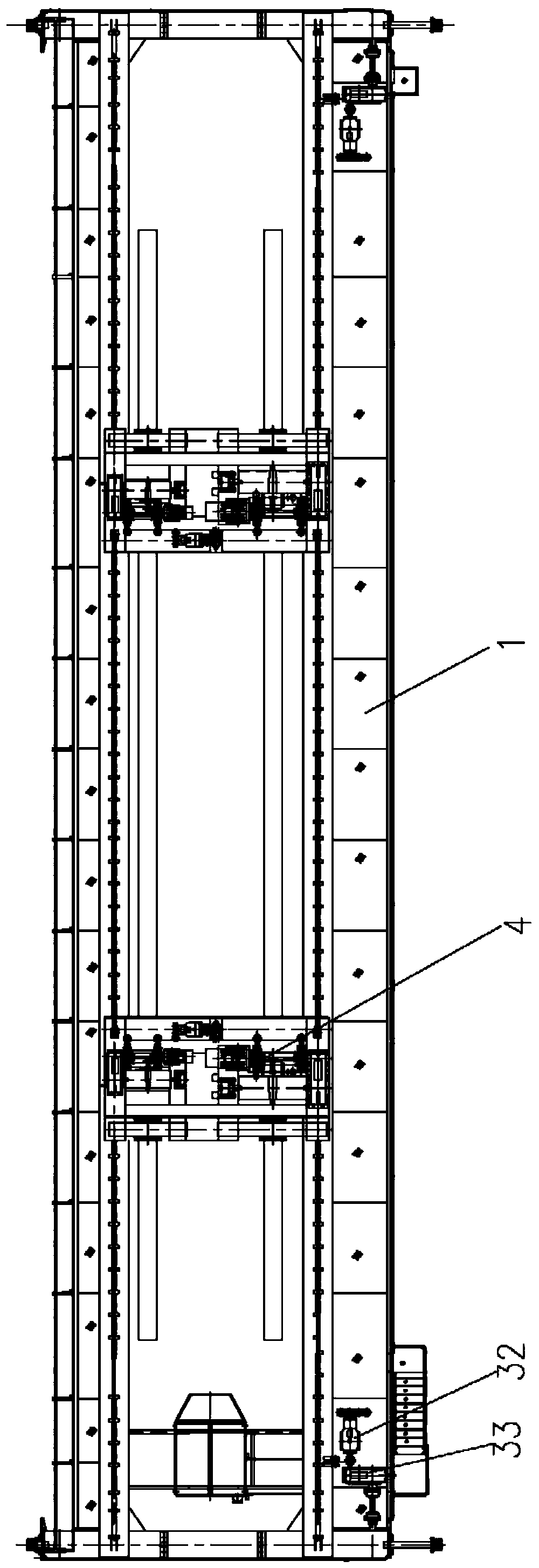

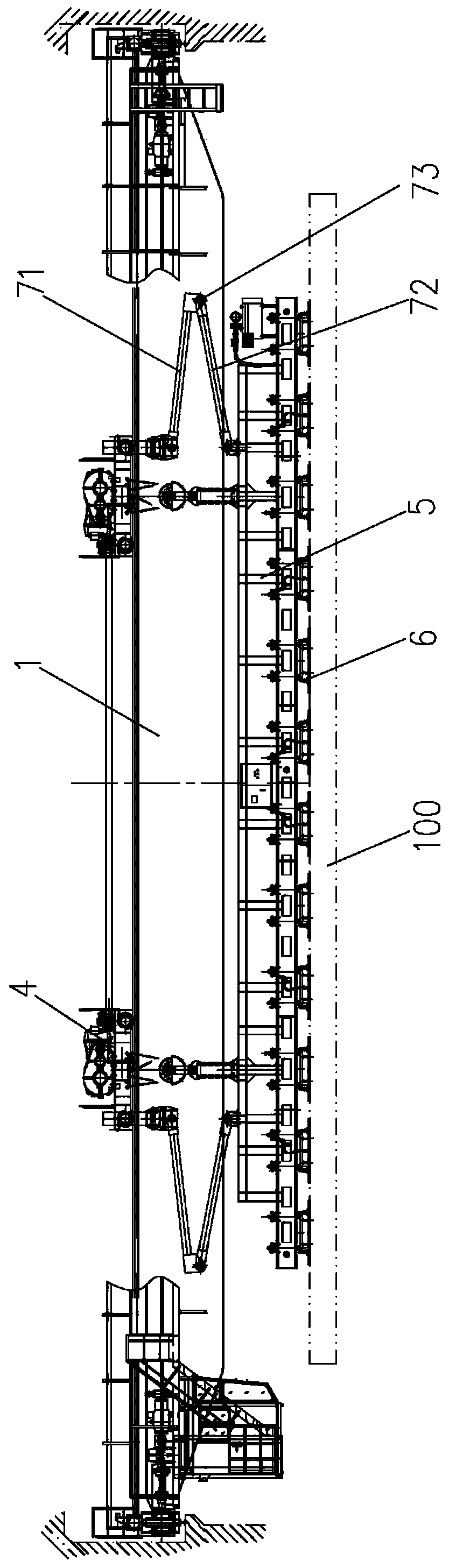

[0025] Please refer to the attached figure 1 to attach Image 6 As shown, the present invention is a square pile vacuum suction cup bridge crane, which is used for hoisting square piles 100. And several parts such as anti-shake device 7 are formed.

[0026] Wherein, the bridge frame 1 is supported on a steel rail 2 . The bridge running mechanism 3 is arranged at both ends of the bridge 1 , which can drive the bridge 1 to travel along the extending direction of the steel rail 2 .

[0027] The bridge running mechanism 3 includes a traveling wheel 31 , a traveling motor 32 and a reduction box 33 . The traveling wheels 31 are located on the rail 2 and can rotate along the rail 2 . The traveling motor 32 is installed on the bridge frame 1, is connected with a reduction box 33, and drives the traveling wheels 31 to rotate.

[0028] The lifting trolley 4 is installed on the bridge frame 1, which is connected to the suspension beam 5, and can drive the suspension beam 5 to go up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com