Thermal-insulation prefabricated direct-buried pipe

A prefabricated direct-buried and heat-insulating technology, applied in the field of composite pipes, can solve the problems of hidden safety hazards and easy falling off of direct-buried pipes, and achieve the effect of improving safety and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

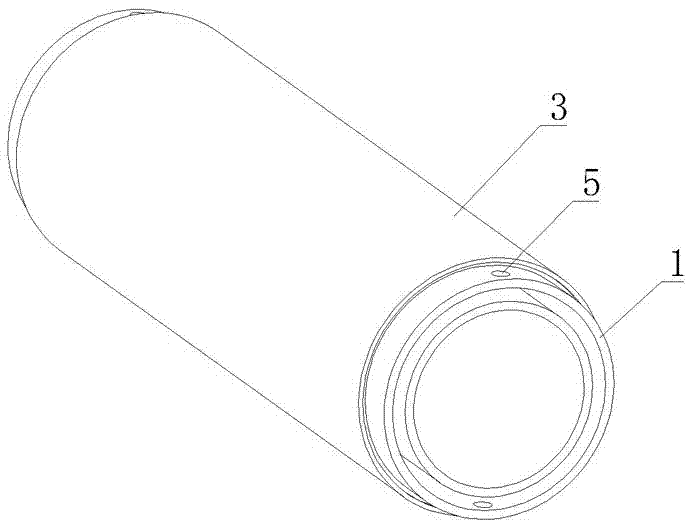

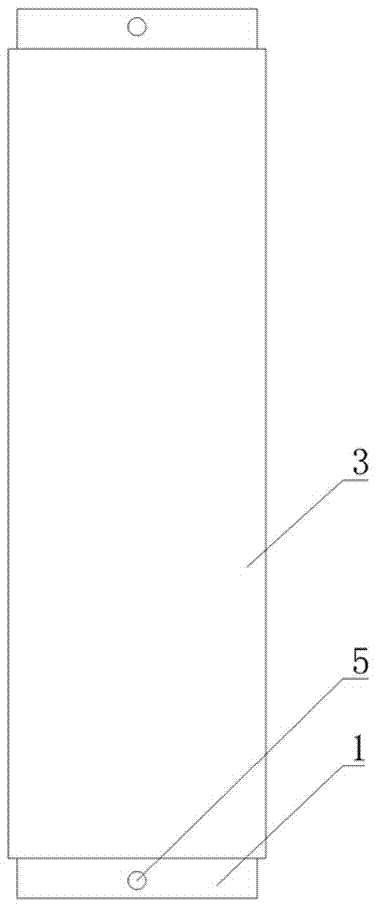

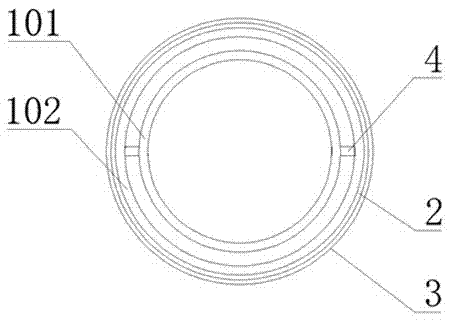

[0016] Such as figure 1 , figure 2 , image 3 As shown, the thermal insulation prefabricated direct-buried pipe includes precast concrete layer 1, insulation layer 2 and protective layer 3 arranged sequentially from inside to outside. A layer 101 and an outer layer 102 are formed. The inner layer 101 and the outer layer 102 are separated from each other to form a cavity. The inner layer 101 and the outer layer 102 are fixed by connecting pieces 4 . The outer layer 102 is provided with openings 5 at both ends.

[0017] Such as Figure 4 As shown, in the preferred embodiment, the openings 5 are two of different sizes arranged along the pipe wall, the precast concrete layer 1 is embedded with seamless steel pipes, the insulation layer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com