Lifting appliance for crane

A spreader and crane technology, which is applied in the field of crane spreaders, can solve problems such as insufficient gripping force, rainwater corrosion, and small grabbing area, and achieve the effects of easy reinforcement and limitation, easy lifting, and convenient storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

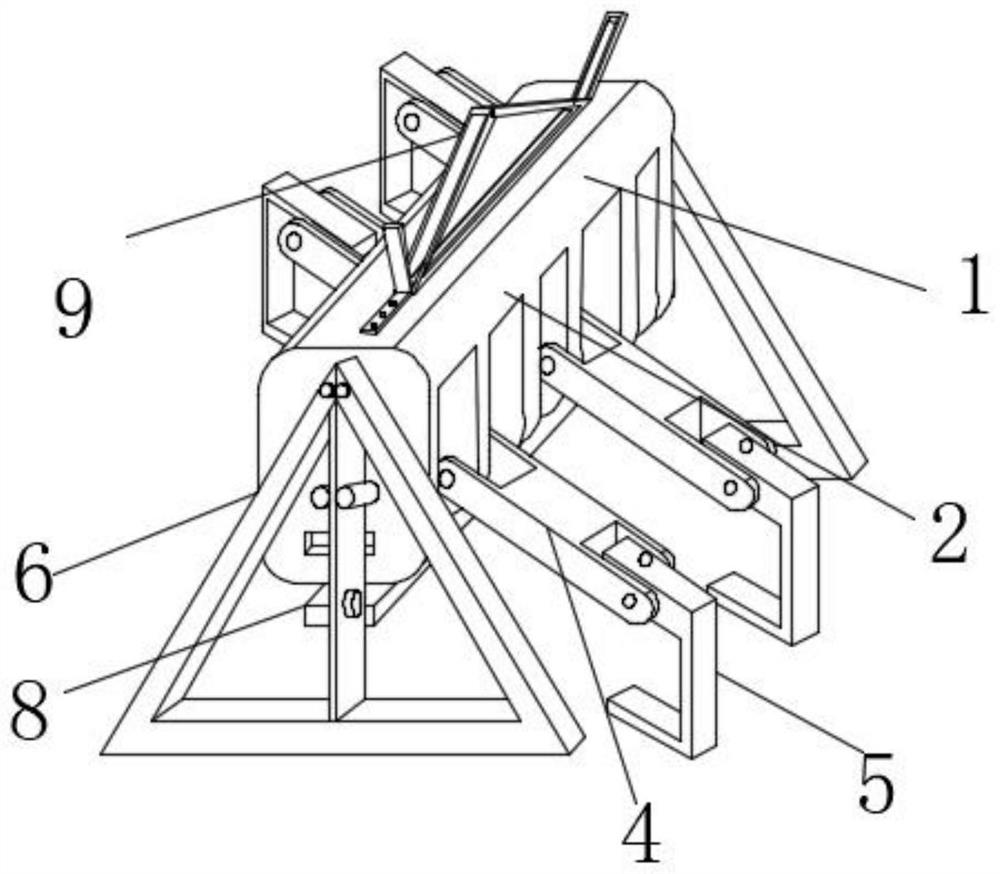

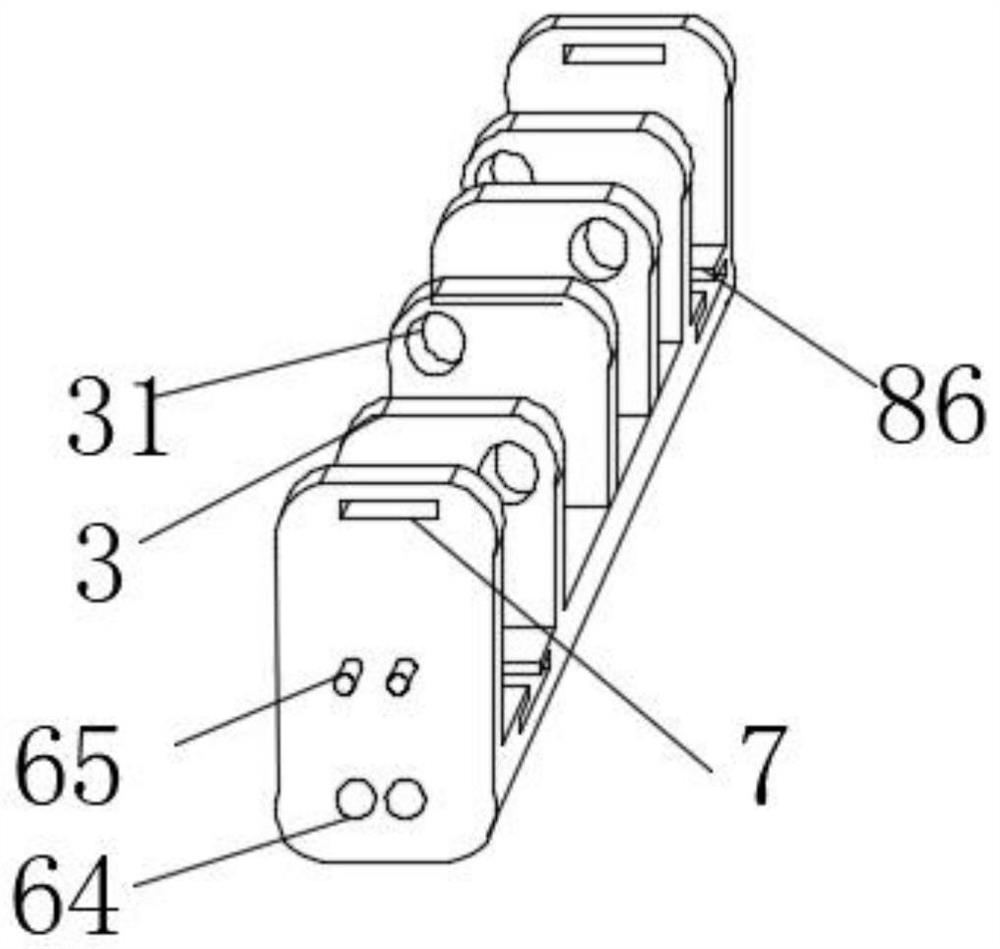

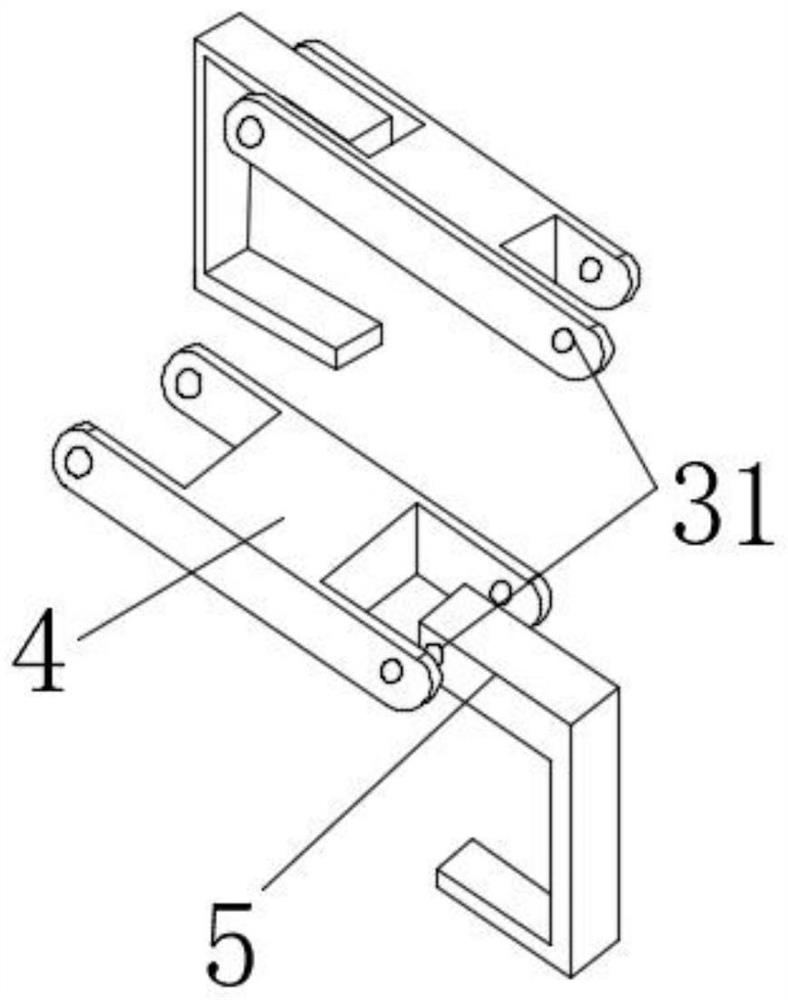

[0041] As an embodiment of the present invention, a lifting mechanism 9 is movably installed on the outer surface of the upper end of the rectangular plate 2, and the lifting mechanism 9 is composed of a triangular frame 91 and an acute-angle splint 92, and the number of the acute-angle splint 92 is two. The two acute-angle splints 92 are front-to-back symmetric, and both of them are fixedly installed on the positions of the front and rear end outer surfaces of the triangular frame 91 respectively. The front and rear end outer surfaces of frame 91 are all provided with empty groove 94, and the inside of triangular frame 91 is provided with transverse groove 95 near the position of lower end, and the inside of described acute angle splint 92 is provided with slotted hole 96 near the position of upper end, and its quantity There are several, the internal thread of the slot hole 96 is connected with a bolt, and the internal thread of the bolt passing through the slot hole 96 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com