A steel cage lifting structure

A lifting structure and reinforcement cage technology, applied in the field of reinforcement cages, can solve problems such as safety accidents, separation of reinforcing hoop and main reinforcement, and no clear requirements, and achieve the effect of ensuring lifting safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

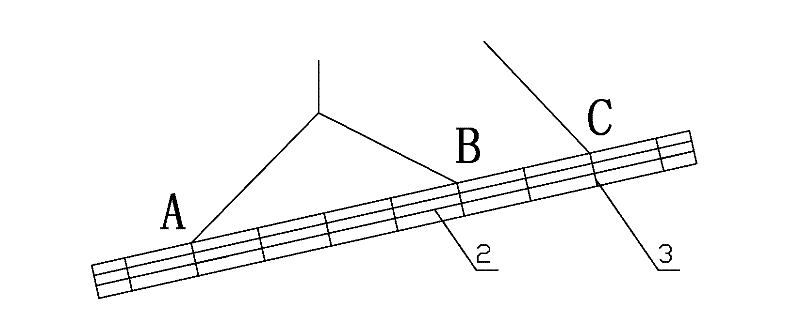

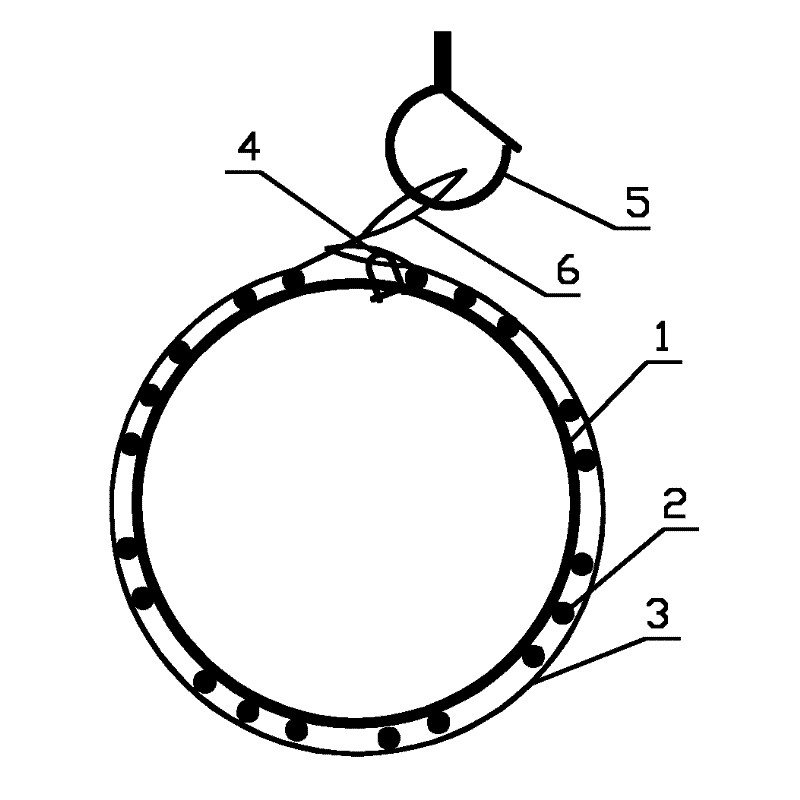

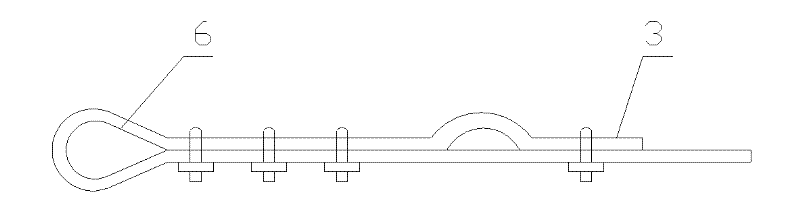

[0011] Such as Figure 1 to Figure 3 As shown, it is an embodiment of a steel cage lifting structure of the present invention. Several rings of reinforcing hoops 1 are welded to the inner ring of the main reinforcement ring 2 of the steel cage, and three steel wire ropes 3 are respectively sleeved on outside of the reinforcement cage and tighten the reinforcement cage. Both ends of the steel wire rope are provided with collars 6, one of which passes through the other end collar and hangs on the hook 5, and the other end collar is locked together with the reinforcing hoop through the shackle 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com