Measuring assembly and bucket positioning hole and lug plate measuring device

A technology for measuring components and measuring devices, applied in the field of measuring tools, can solve the problems of difficult and accurate measurement of dimensions, affecting assembly accuracy, etc., and achieve the effect of improving measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

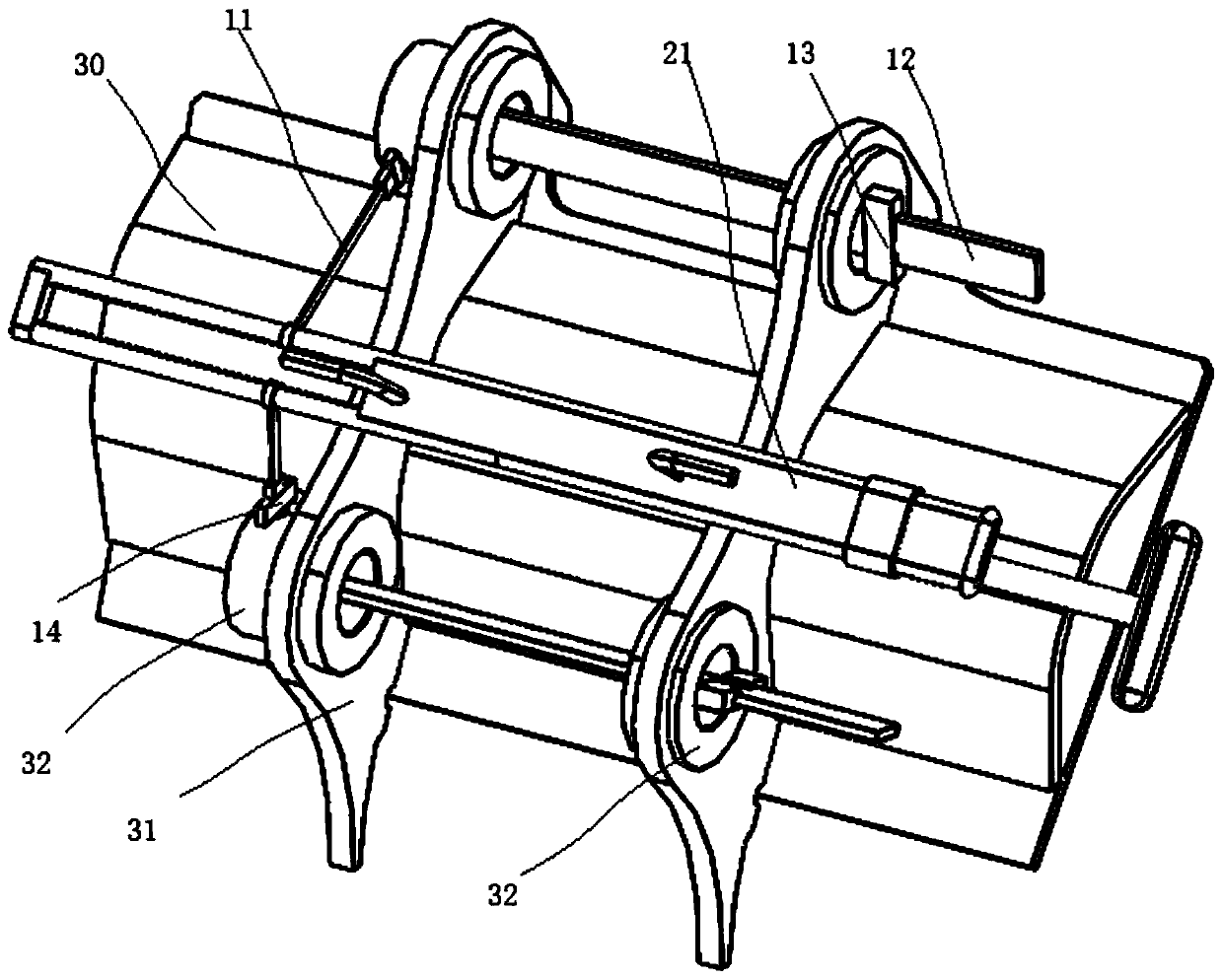

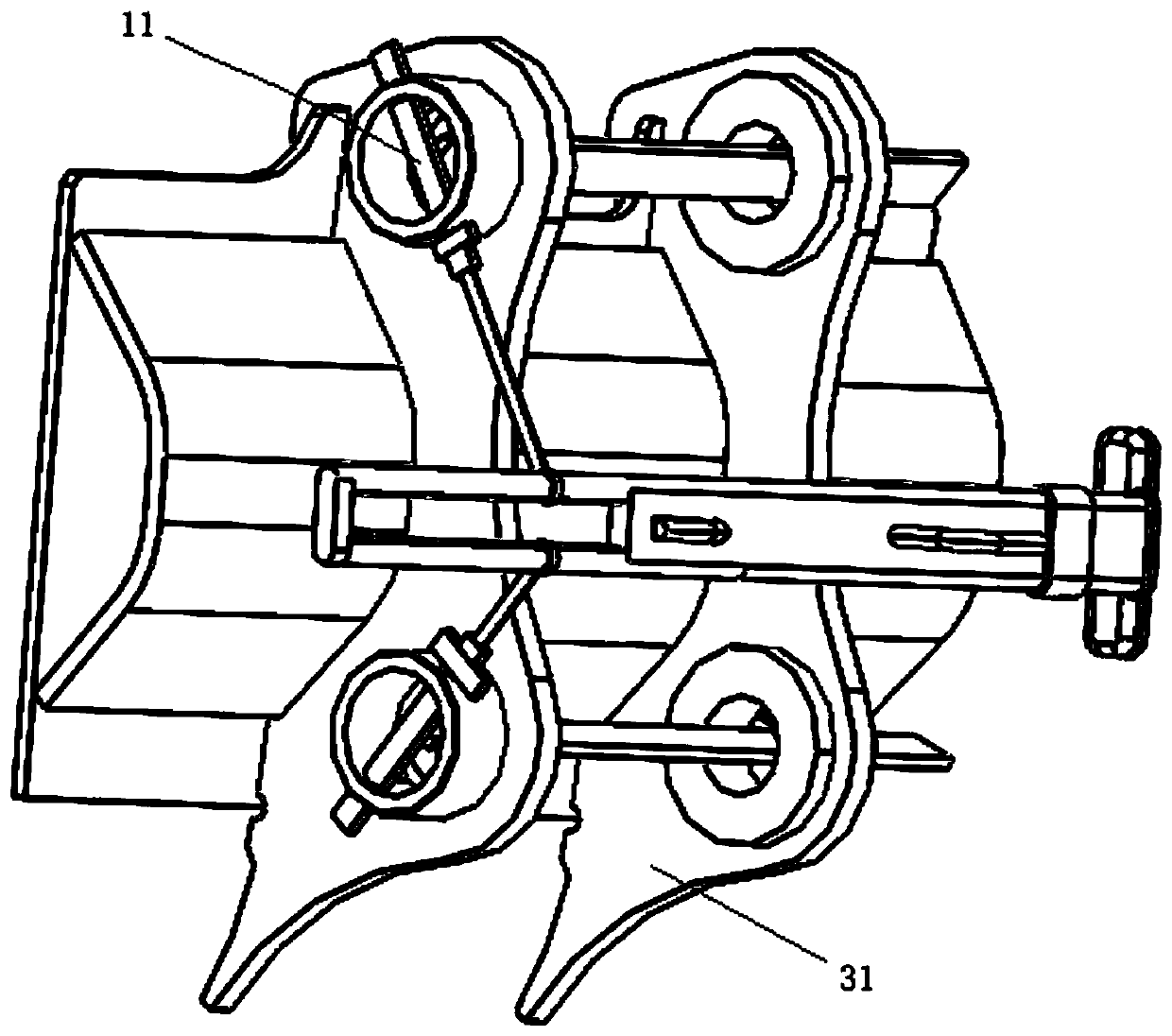

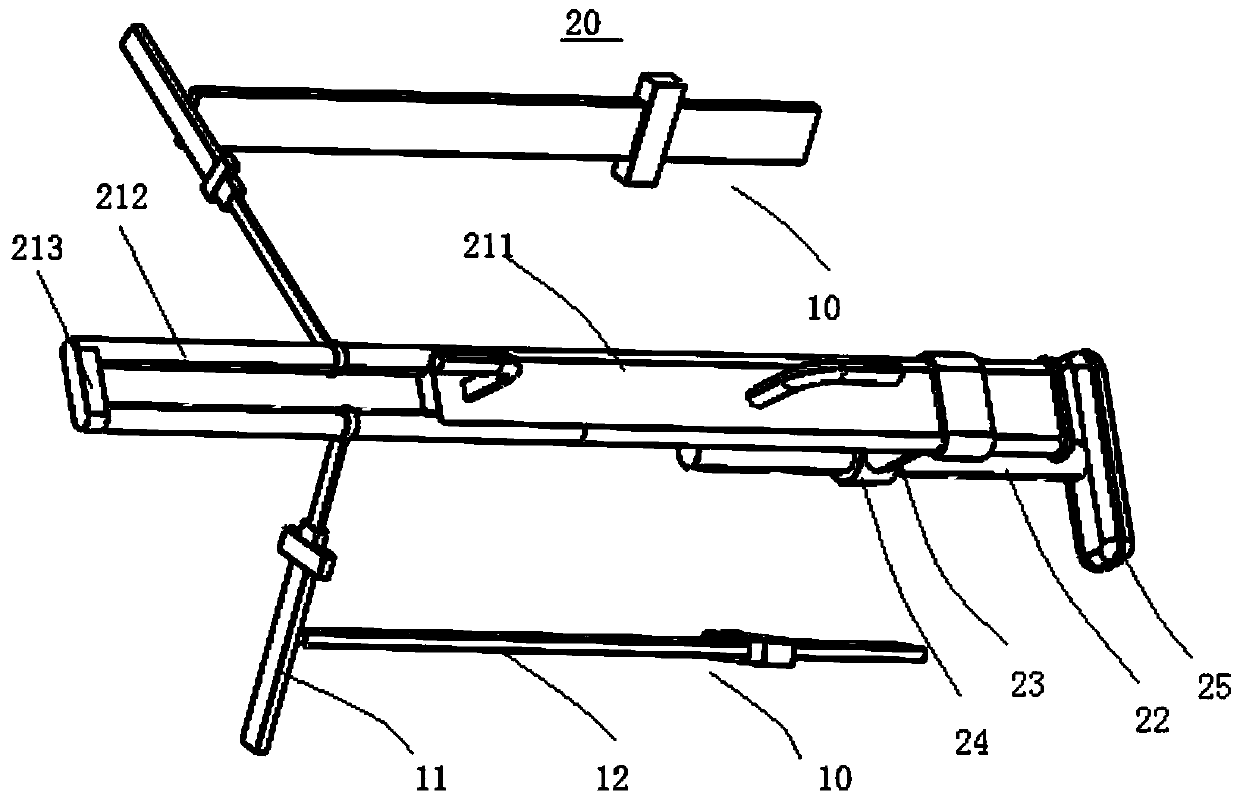

[0042] Please refer to Figure 1-Figure 4 , the bucket 30 in the figure includes a bucket body and two lugs 31, and the two lugs 31 are welded on the back of the bucket body, and the lugs 31 are connected to the small arm of the excavator through a pin shaft (not shown in the figure). not shown) connection. In order to install the pin shaft, two sets of bushings 32 are arranged on the ear plate 31 , and two bushings 32 in each set of bushings 32 are coaxially arranged. In order to prevent the pin shaft from rotating around its own axis in the shaft sleeve 32, a positioning hole 321 is arranged on the shaft sleeve 32 and the pin shaft, and the positioning hole 321 extends radially along the shaft sleeve 32; Able to lock the pin shaft. Since the distance between the axis of the positioning hole 321 and the right ear plate 31 (refer to the figure) can affect the final assembly accuracy, it is necessary to accurately measure the above distance.

[0043] The positioning hole 321...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com