An anti-blocking material device and a screening machine with the same

A sieving machine and anti-blocking technology, which is applied in the fields of filtration, solid separation, chemical instruments and methods, etc., can solve the problems that the anti-blocking performance of the screen cannot be effectively realized, and the beating effect is reduced, and the anti-blocking effect is obvious, The effect of prolonging the service life and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

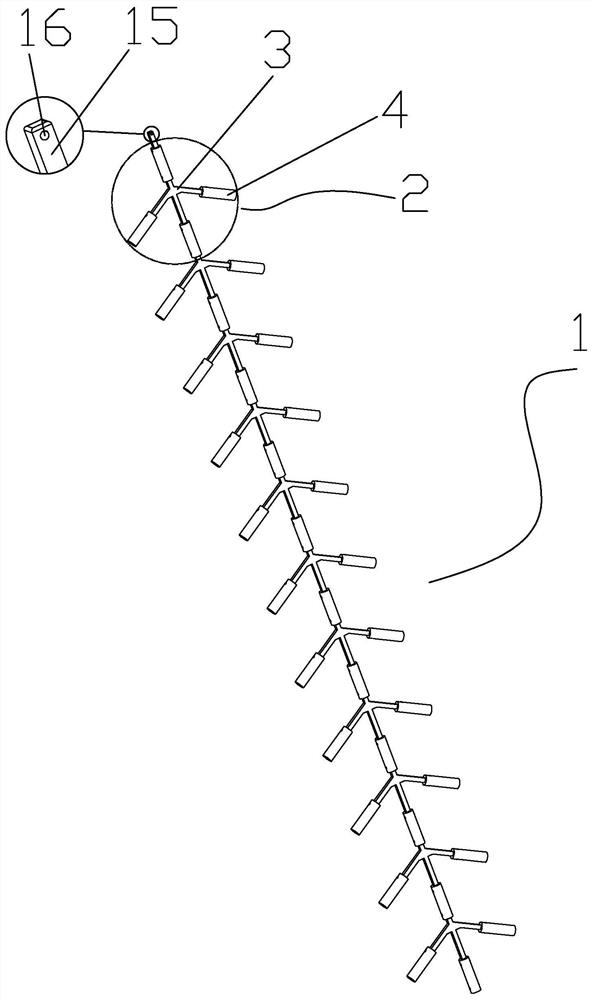

[0042] exist figure 1 , figure 2 , image 3 In the embodiment shown, an anti-clogging device includes:

[0043] The anti-blocking flapping main body 1 is arranged on the mesh surface of the screen mesh to automatically flap and prevent the screen mesh from being blocked. One end of the main body 1 is fixedly connected to the screen at the blanking end of the screening machine, while the other end is freely set along the material movement direction.

[0044] The anti-blocking flapping body 1 includes a plurality of flapping units 2 connected in series;

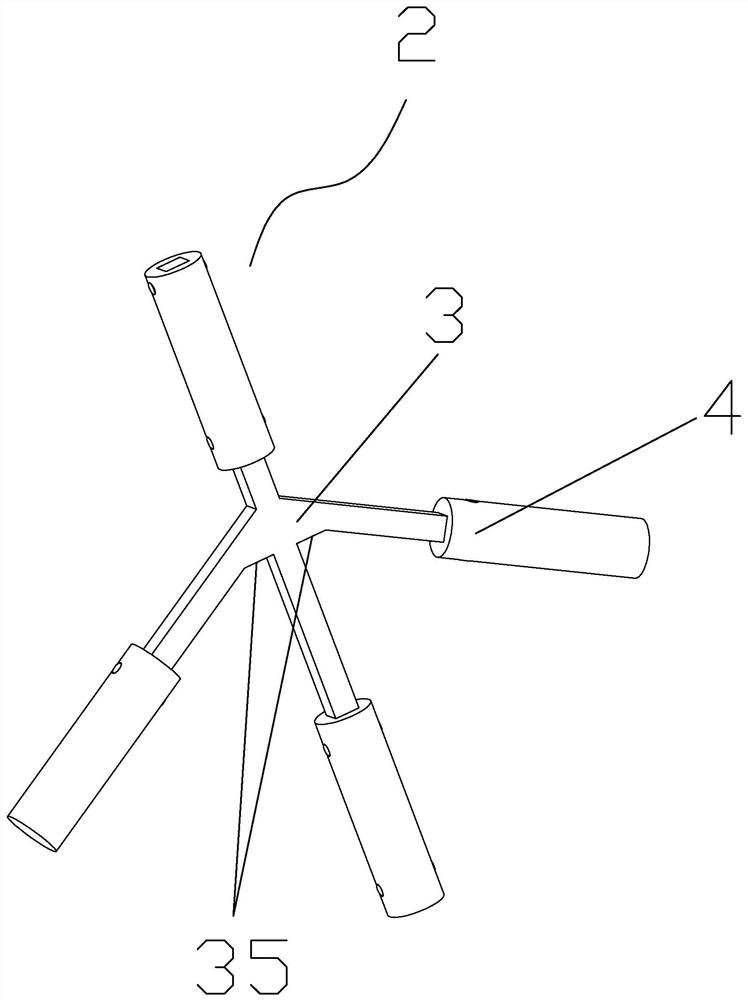

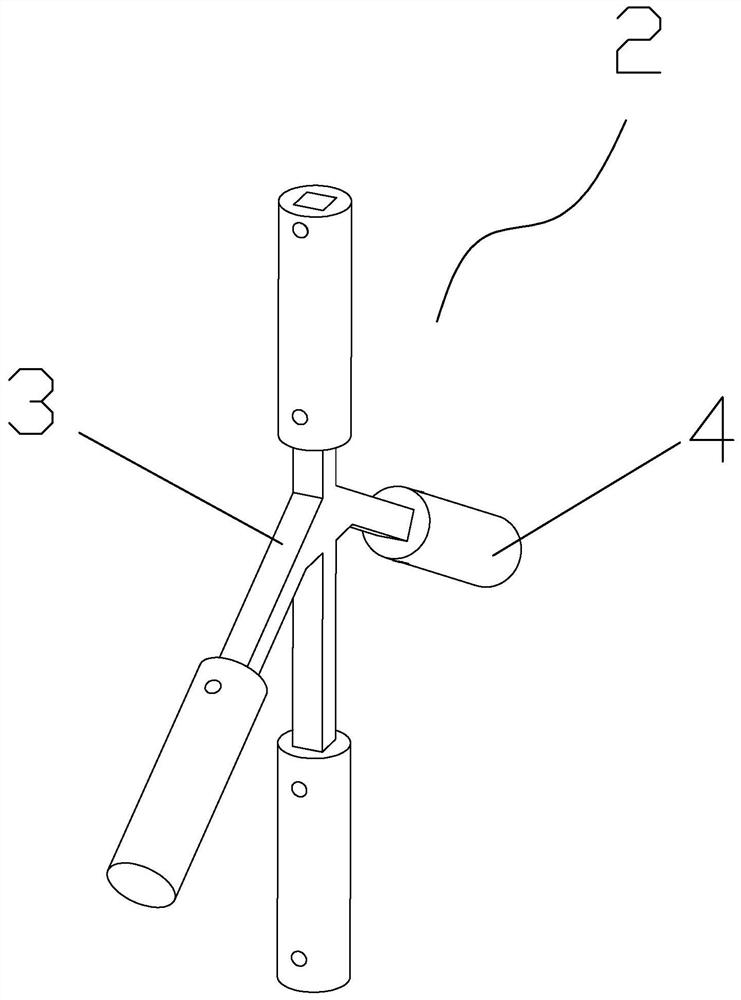

[0045] Each flapping unit 2 includes a flapping whip rod 3 and a flapping whip head 4; in this embodiment, the flapping whip rod 3 and the flapping whip head 4 are respectively made of rubber materials, and the hardness of the flapping whip rod 3 is smaller than that of the flapping whip head 4 hardness. The Shore hardness of the material of the whipping rod 3 is HA50-HA75; the Shore hardness of the whipping tip 3 is HA80...

Embodiment 2

[0058] exist Image 6 , Figure 7 In the embodiment shown, an anti-clogging material device has basically the same technical scheme, except that the screening machine in this embodiment is a vertical screening machine, and the Shore hardness of the material for flapping the whip rod 3 is HA50. ; The Shore hardness of the whip tip 3 is HA 80. The beating unit is a hierarchical multi-whip structure, and in this embodiment, it is a secondary beating unit. Each level of whipping whip includes a plurality of graded whips, and the whipping whip 3 includes an integrated connecting whip 31, a plurality of first-level whips and a plurality of second-level whips, and the first-level whip includes a first-level first whip The rod 32', the first-level second whip 33' and the first-level third whip 34', the second-level whip includes the second-level first whip 32" and the second-level third whip 34"; the second-level first whip The rod 32'' and the second-level third whip 34' are respe...

Embodiment 3

[0061] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, except that the Shore hardness of the material of the whipping rod 3 is HA75; the Shore hardness of the whipping tip 4 is HA95. The included angle between the first whip 32, the third whip 34 and the second whip 33 is 75 degrees.

[0062] For the anti-clogging device described in the above embodiment, the Shore hardness of the material of the whip rod 3 is HA50~HA75, the minimum tensile strength is 45Mpa, the minimum elongation is 600%, the minimum shearing capacity is 65KN / m, and the temperature range- 60°C to +60°C. The whipping rod 3 may also be a flat rubber product, or the whipping whip may be a cylindrical rubber product. The shape of the flapping whip can be set accordingly as required.

[0063] The Shore hardness of the whip tip 4 is HA 80~HA 95. The minimum tensile strength is 52Mpa, the minimum elongation is 545%, the minimum shear capacity is 103KN / m,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com