Process for reducing area and thickness of overlapping area during lithium battery coating

A technology for lithium batteries and overlapping areas, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, electrolyte batteries, etc., and can solve problems such as easy generation of air bubbles, warping, and affecting the overall size of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

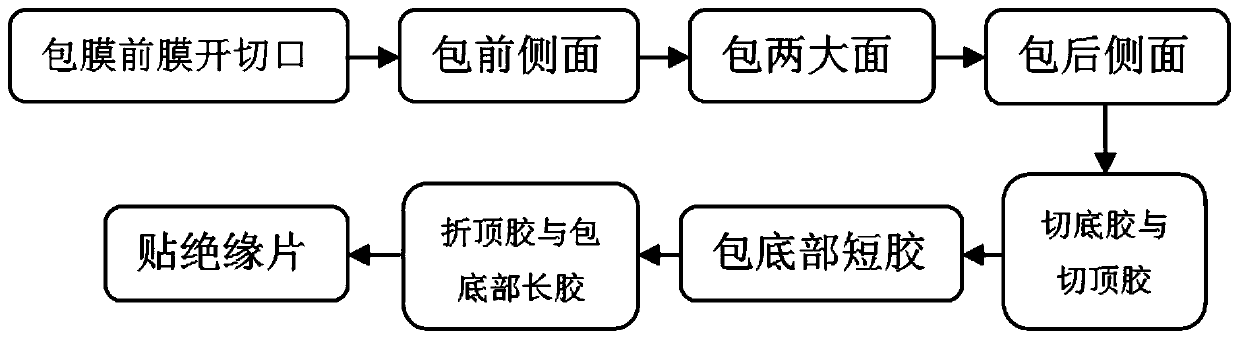

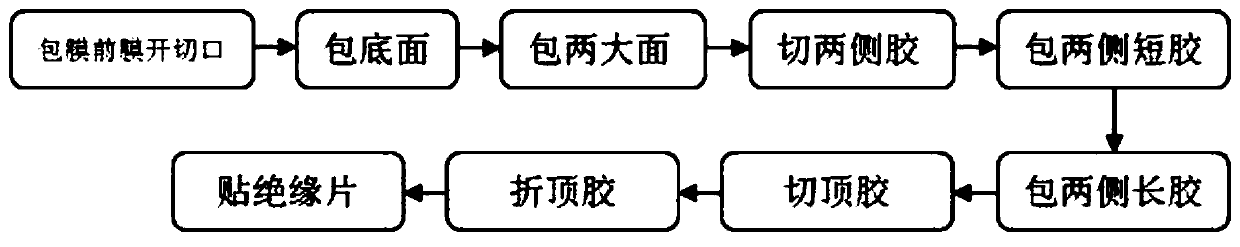

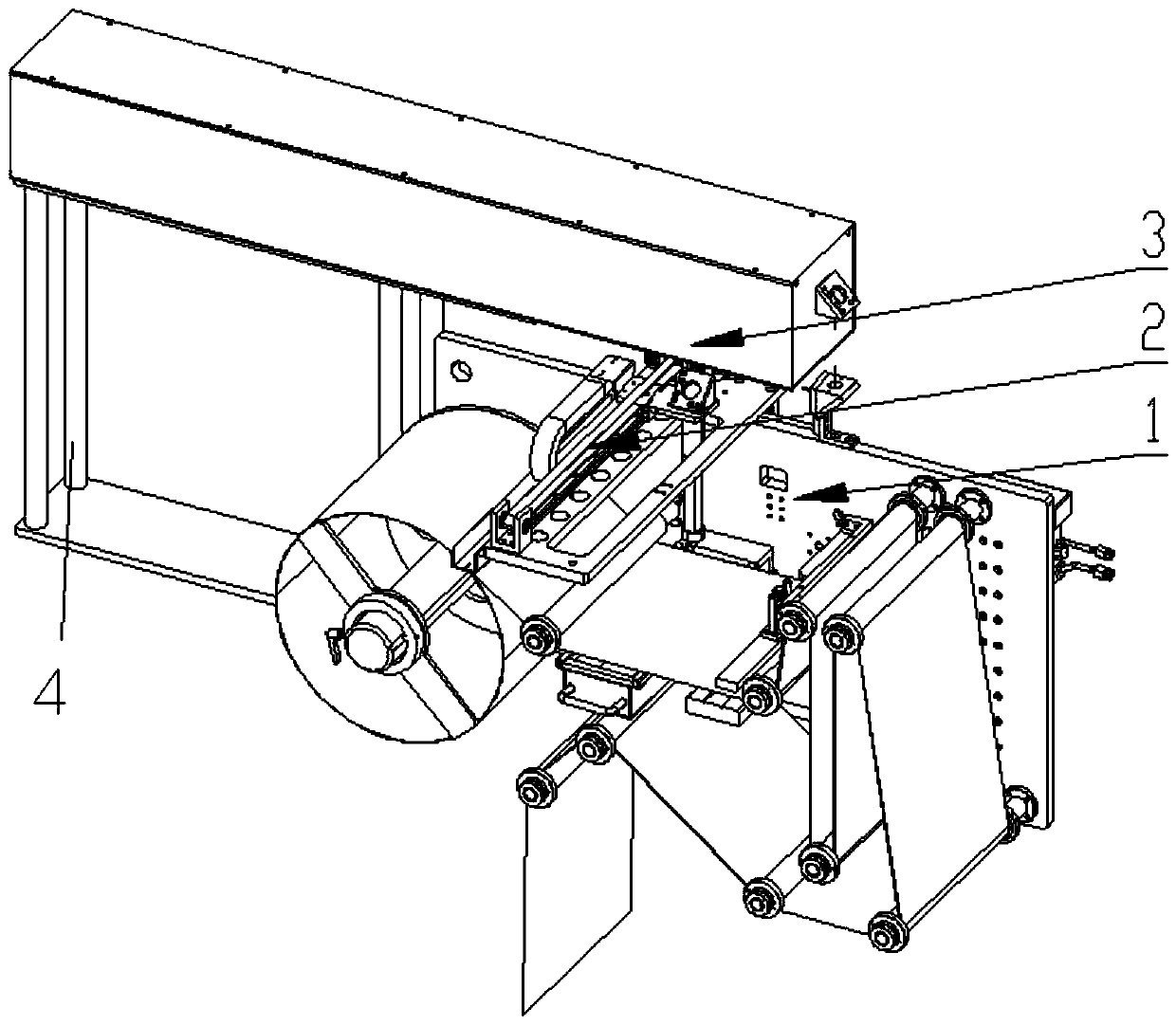

[0019] see figure 2 with image 3 , the present embodiment is a U-shaped coating process, and its specific process is as follows: first, the film is cut by using a power square lithium battery with a laser cutting film unwinding device, and then the bottom surface is wrapped; the two sides are wrapped; the glue on both sides is cut; Short glue on both sides of the bag; long glue on both sides of the bag; then cut the top glue; Adhesive paper unwinding and unwinding assembly 1, laser cutting film moving assembly 2 and laser generator assembly 3; adhesive paper unwinding and ungluing assembly 1 is set up with laser cutting film moving assembly 2 above the front side, and laser generator assembly 3 is set up on the laser cutting machine. The top of the film movement assembly 2, and one end of the laser generator assembly 3 is fixed on the ground with a bracket; when the device is working, the adhesive tape is unwound and the ungluing assembly 1 performs the ungluing movement to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com