A kind of processing method of water meter shell

A processing method and shell technology, applied in the direction of liquid/fluid solid measurement, instruments, measuring devices, etc., can solve the problems affecting the production efficiency of water meter shells and the inconvenience of grinding work, so as to reduce damage, high precision, and reduce waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0044] A processing method for a water meter shell disclosed by the invention comprises the following steps:

[0045] Step SA: using a punching and flanging machine to make a pipe with flanging holes.

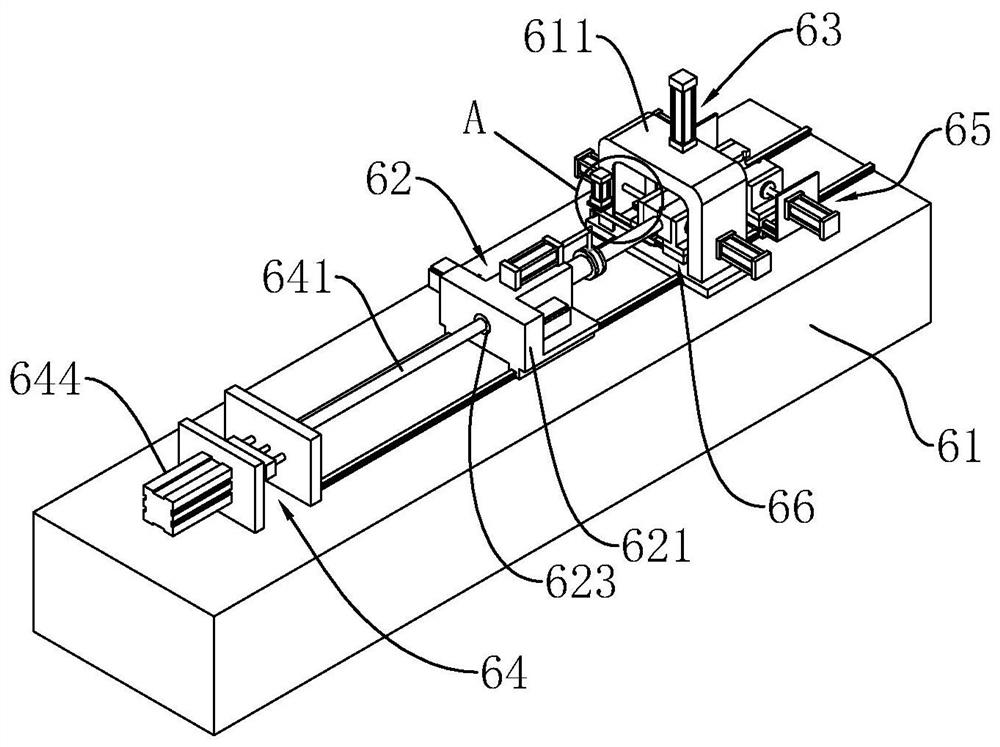

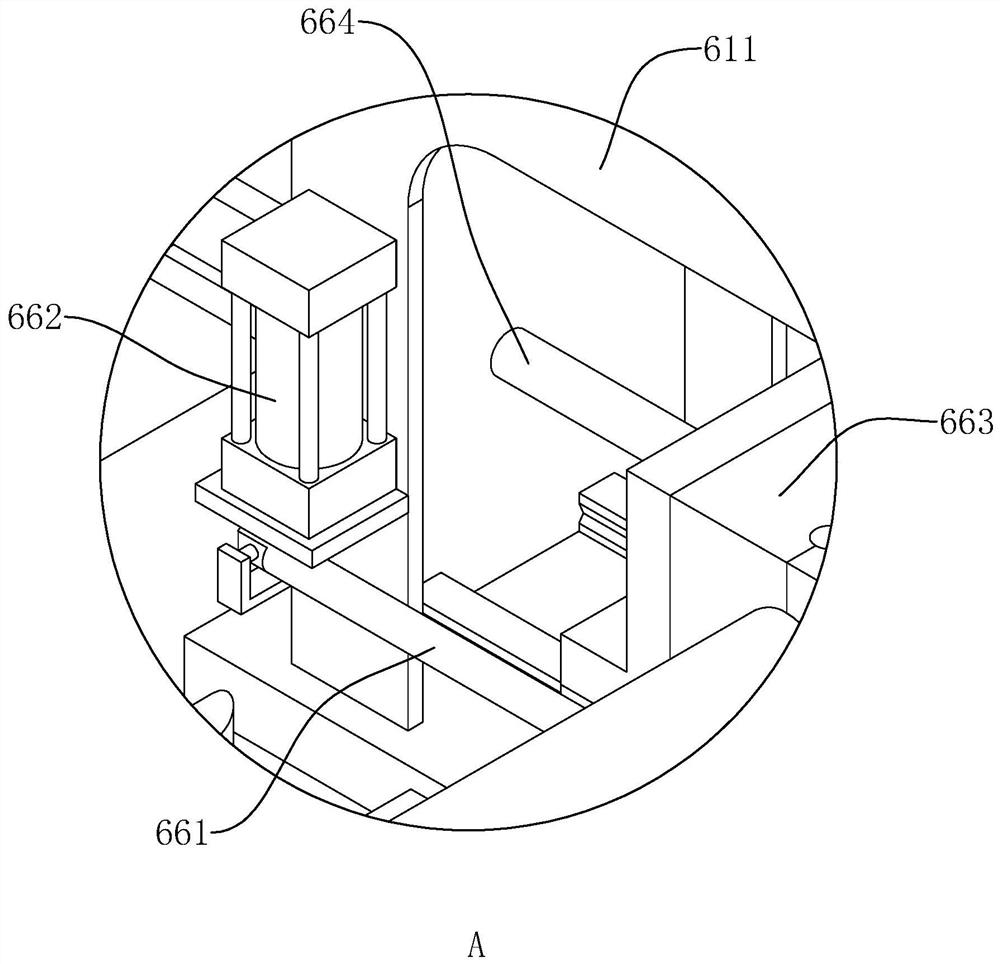

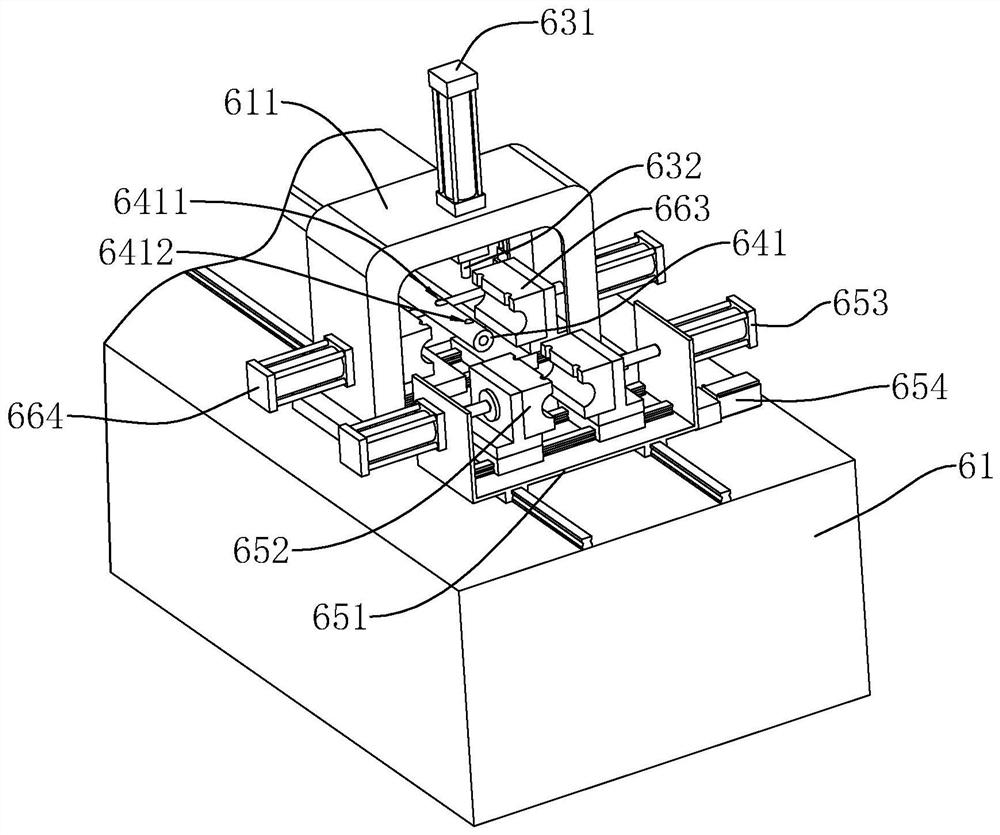

[0046] see figure 1 , the punching and flanging machine includes a workbench 61 and a frame 611 erected on the workbench 61 , the frame 611 is close to one end of the workbench 61 . The workbench 61 is provided with a mobile clamping mechanism 62 , an auxiliary clamping mechanism 65 and a flanging mechanism 64 , and the frame 611 is provided with a punching mechanism 63 and a positioning mechanism 66 . The mobile clamping mechanism 62 and the auxiliary clamping mechanism 65 are respectively located on both sides of the frame 611 along the length direction of the workbench 61 , and the flanging mechanism 64 and the mobile clamping mechanism 62 are located on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com