Grabbing and lifting mechanism for railway cantilever mounting robot

A technology of robots and grasping mechanisms, applied in the directions of manipulators, lifting devices, program-controlled manipulators, etc., can solve problems such as non-matching, and achieve the effects of efficient installation, high convenience, and reliable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

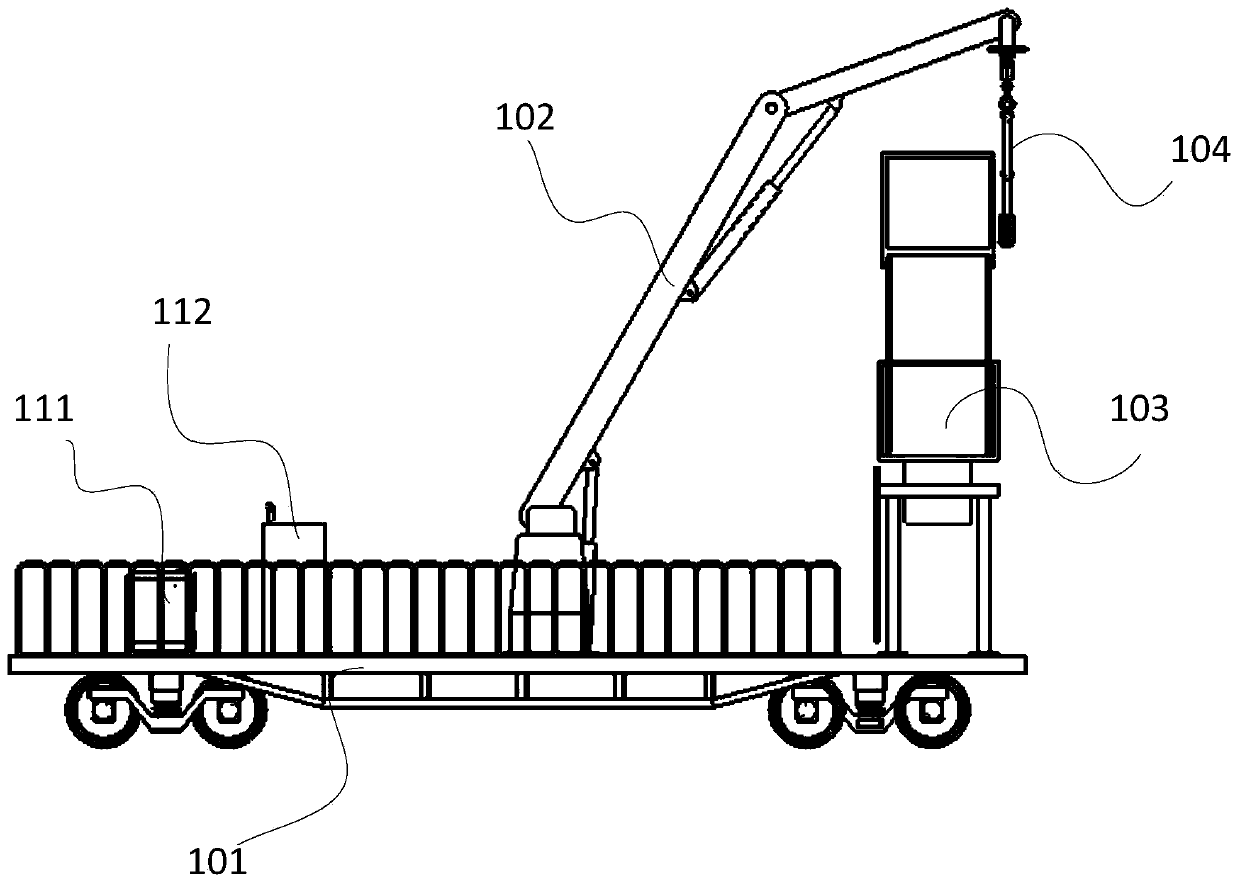

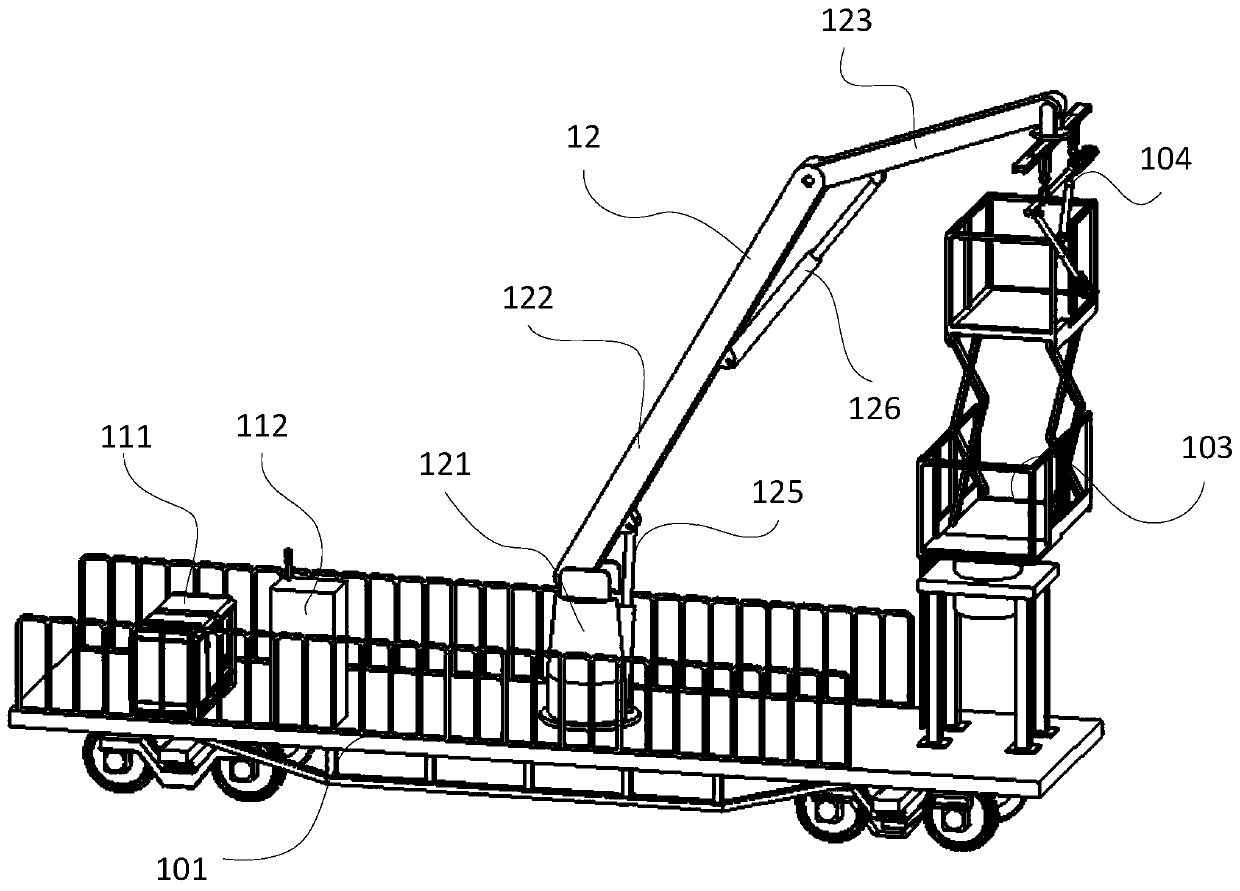

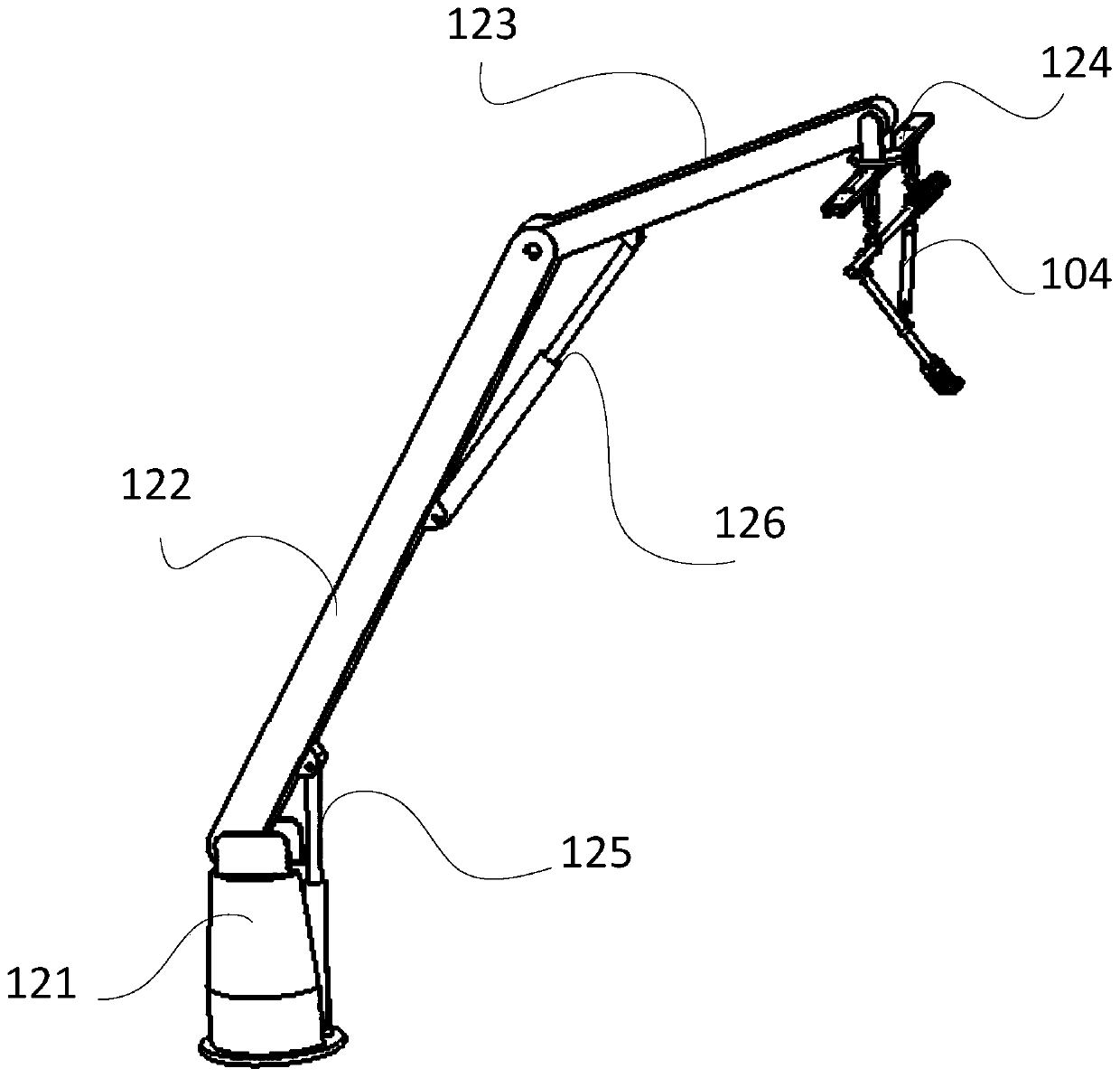

[0036] Such as Figure 1 to Figure 9 As shown, this embodiment provides a railway arm arm installation robot, which travels along the track direction and lifts the arm arm 104 to the installation position of the catenary pillar. It should be noted that the serial numbers such as "first" and "second" in this embodiment are only used to distinguish similar components, and should not be understood as specific limitations on the scope of protection. In addition, directional terms such as "bottom", "top", "surrounding edge", and "center" in this embodiment are described based on the drawings. In addition, the structure of the track vehicle in this embodiment is similar to that of the track inspection vehicle, so its internal structure will not be described in detail here; not only that, the control box in this embodiment is purchased, and it is obtained by wiring conventional controllers and electrical components. , and the control program can be realized by a combination of conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com