A percussion device for microseismic positioning and correction in deep rock mass

A positioning correction, deep-seated technology, applied in measuring devices, using sonic/ultrasonic/infrasonic waves to analyze solids, instruments, etc. Inexpensive and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

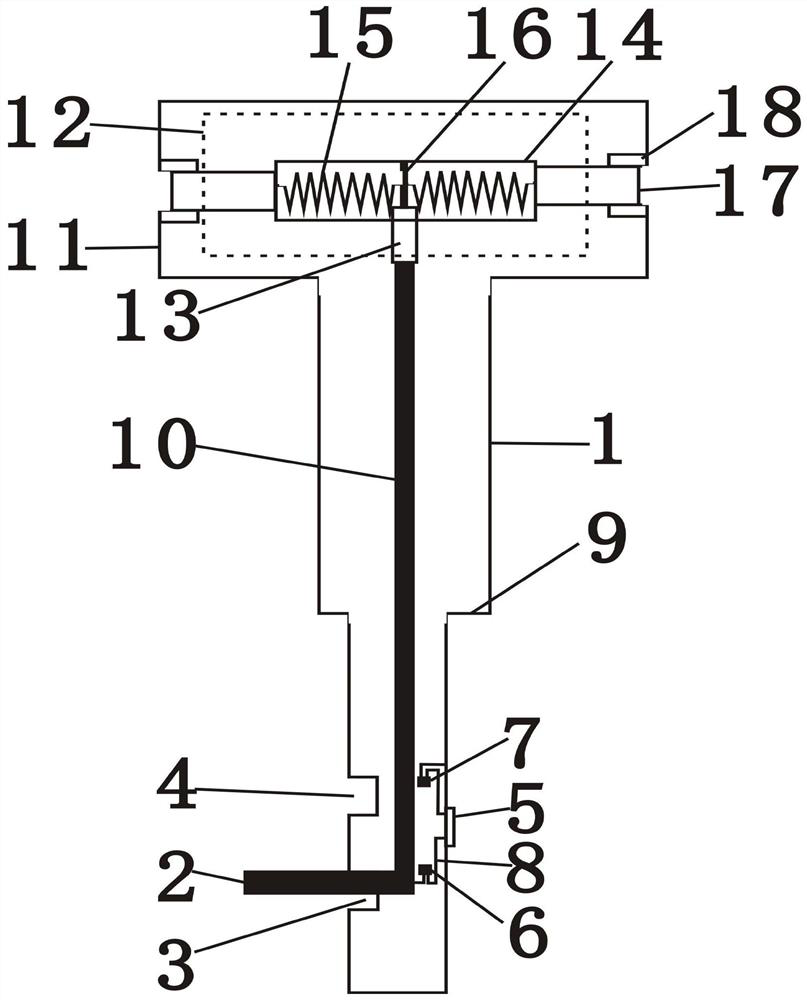

[0020] A percussion device for positioning and correcting microseismic deep rock mass, comprising: a main body system, a control system, an elastic system, a timing system, and a percussion system, and the control system, the elastic system, the timing system, and the percussion system are all installed on the On the main body system, the control system is respectively connected with the elastic system and the timing system, the control system is used to simultaneously trigger the elastic system and the timing system, and the knocking system is connected with the elastic system.

[0021] The main system includes: a shell 1, a bayonet A3, a bayonet B4, an expansion joint 9, an impact chamber 11, and an upper cover 12. The shell 1 is provided with the bayonet A3 and the bayonet B4, and the shell 1 is An adjustable length telescopic joint 9 is provided, the impact chamber 11 is connected with the casing 1 , the upper cover 12 is arranged on the impact chamber 11 , and a scale mark...

Embodiment 2

[0031] The invention develops a portable, easy-to-operate and low-cost percussion device for deep rocks.

[0032] The device includes a main body system, a control system, an elastic system, a timing system and a knocking system. It is suitable for avoiding the correction of the positioning system in the early stage of microseismic monitoring due to the cracks generated by the disturbance of surface excavation.

[0033] (1) Main system

[0034] The main system is mainly composed of shell 1, bayonet A3, bayonet B4, expansion joint 9, impact chamber 11, and upper cover 12.

[0035] (2) Control system.

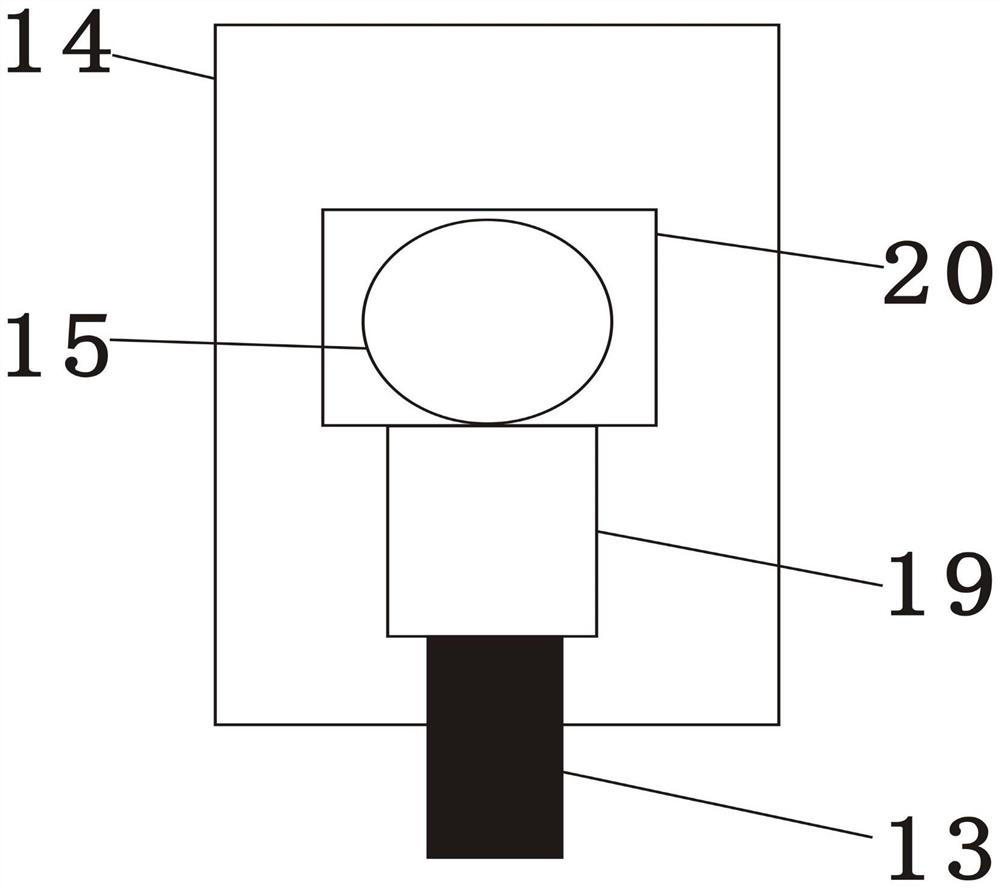

[0036] Control system is mainly made up of control handle 2, control rod 10, control button 13, push rod 19, baffle plate 20.

[0037] (3) elastic system

[0038] The elastic force system is mainly made up of spring chamber 14, spring 15, fixed plate 16.

[0039] (4) Timing system

[0040] The timing system is mainly composed of a timer 5, a positive plate 6, a negative plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com