Table board structure used on back of train or airplane seat

A technology of aircraft seats and table boards, which is applied to the layout of seats, aircraft parts, seats, etc., to achieve the effect of ensuring normal use and riding comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

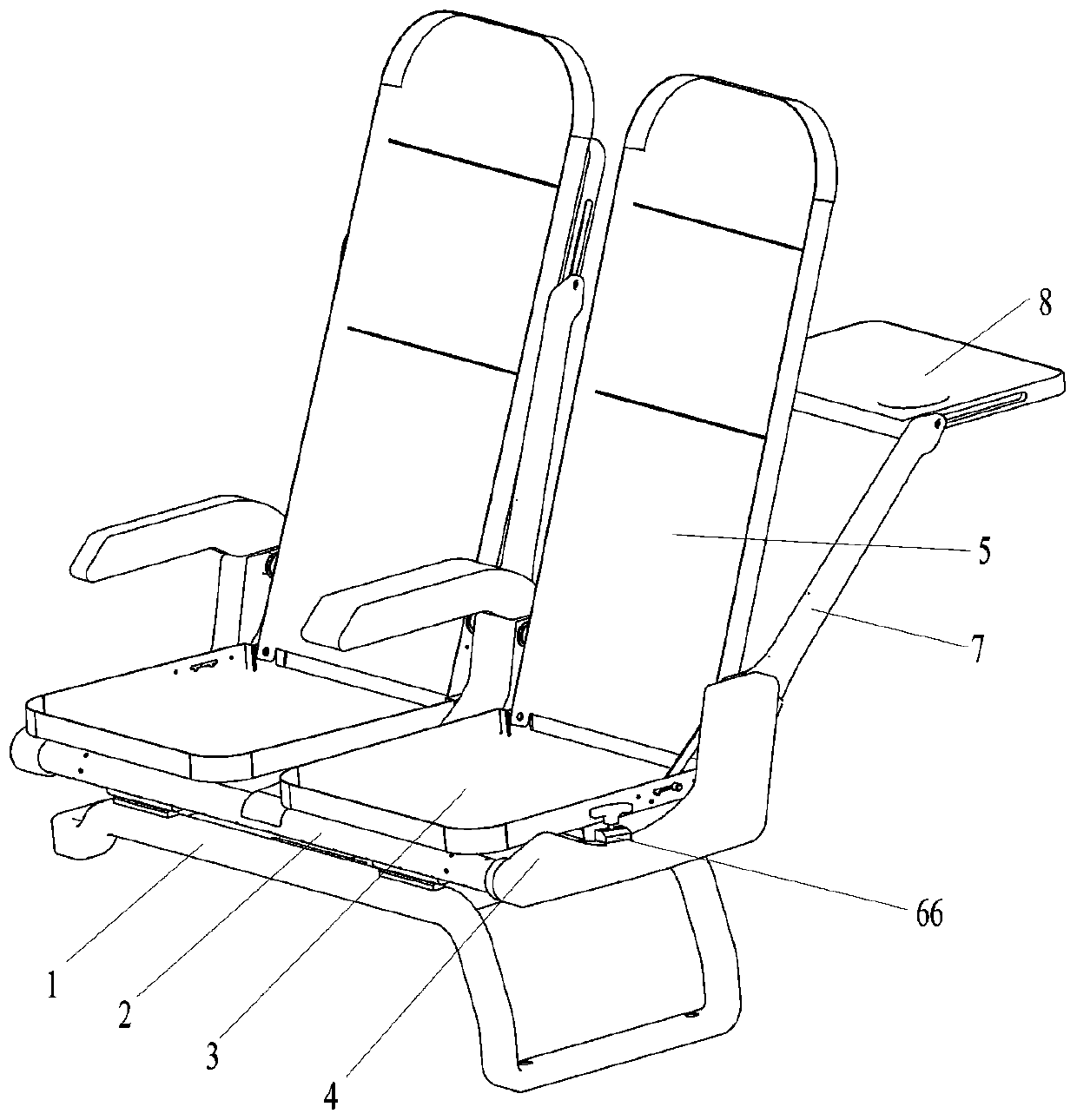

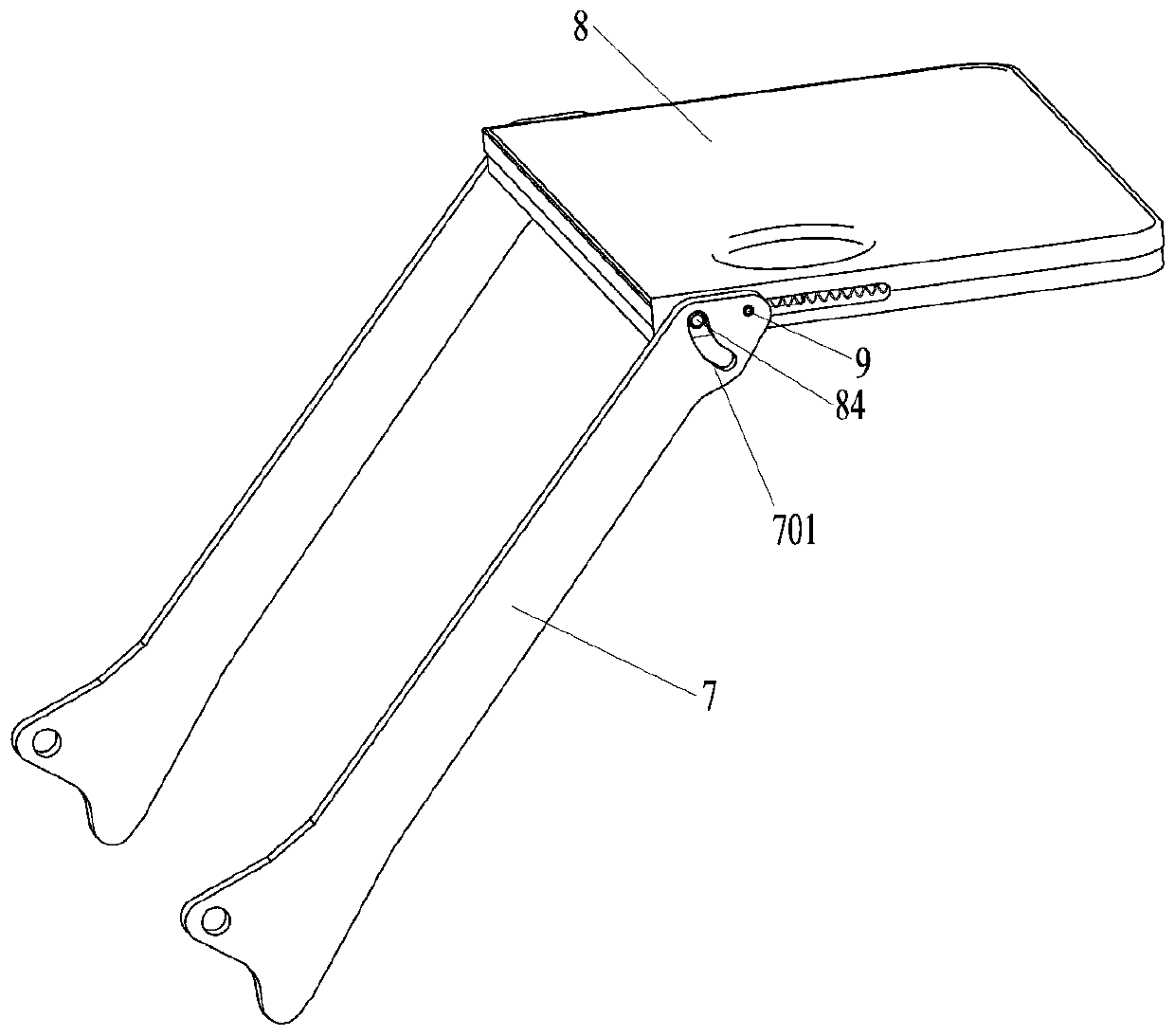

[0033] Such as Figure 1 to Figure 5 Shown, a kind of table board structure that is used on the back of train or aircraft seat described in this embodiment, table board structure comprises table board support, table board, one end of table board support is installed with the seat that is used to install seat The arm is hinged, and the other end is hinged with the table. The back of the seat is provided with a rotating buckle, which can limit the free end so that the free end and the seat move synchronously. The seat and the seat mounting arm 4 slide connected, and the seat swings around a certain point in the front and back direction of the seat. Here, the bottom support of the seat or the seat mounting arm 4 is not limited in this example. It only needs to satisfy that the seat can swing. The so-called swing means around a certain point Make an arc back and forth. The table bracket and the table hinge are equipped with a retractable compensation mechanism; when the table is ...

Embodiment 2

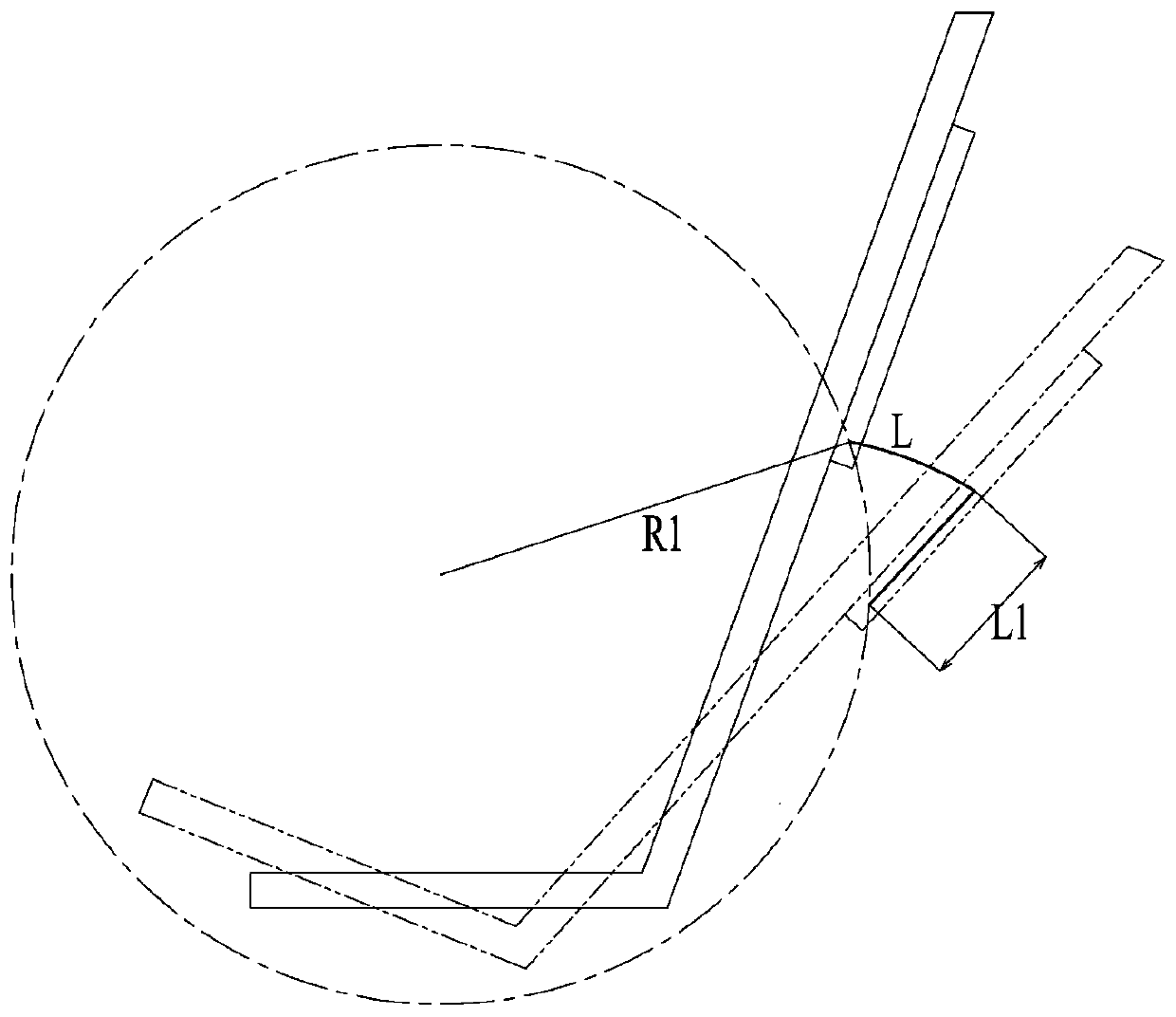

[0041] This embodiment is a further limitation of the first embodiment above, and further defines the structure of the seat for swinging, such as Figure 6 to Figure 8 As shown, there are two seat mounting arms 4 in this embodiment, which are symmetrically arranged on the left and right sides of the seat to jointly support the seat, that is, one seat corresponds to two left and right seat mounting arms. The seat is supported by a support frame. The support frame includes a base frame 1 and a swivel frame 2 . The swivel frame 2 is rotatably connected to the base frame 1 . Seat installation arm 4 is provided with guide rail 41, and guide rail 41 is arc-shaped, and the seat is provided with the arc-shaped second slide block 61 that matches guide rail 41, and seat is connected with guide rail 41 by second slide block 61 so that all Said seat swings in the front-rear direction. Seat here is made up of cushion board 3, backboard 5, and cushion board 3 is connected with backboard 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com