Polyurethane elastomer used as counterweight guide shoe lining and preparation method and application of polyurethane elastomer

A technology of polyurethane elastomer and polyurethane prepolymer, which is applied in the field of polyurethane elastomer, can solve the problems of affecting the ride comfort of elevators, affecting the service life of guide shoes, and high hardness of engineering plastics, achieving long service life, excellent wear resistance, The effect of good damping shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

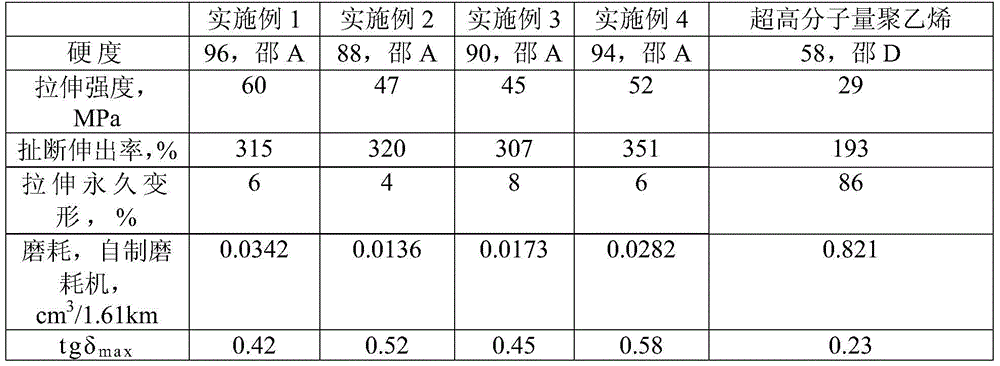

Examples

Embodiment 1

[0024] A preparation method for a polyurethane elastomer used as an elevator counterweight guide shoe lining, comprising the following steps:

[0025] (1) Preparation of polyurethane prepolymer: 63 parts by mass of branched polytetrahydrofuran diol (brand PTG-L1000) with a molecular weight of 1000, 37 parts by mass of polycaprolactone diol (brand PCL210N) with a molecular weight of 1000, methanol Mix 0.6 parts by mass of base silicone oil (brand DM12500) and 1.0 parts by mass of fumed silica (brand R972), heat to 115±5°C, evacuate until the residual pressure is less than 500Pa, keep warm for 2 hours, and then cool down to 55±3 ℃, slowly drop it into 33±3℃, 139 parts by weight of 2,4-toluene diisocyanate, control the dropping speed, and keep the temperature of the reaction mixture system between 60-70℃. After the dropwise addition, keep warm for 1 hour, then raise the temperature to 82±2°C and react for 2 hours; then perform short-path distillation on the reaction mixture until...

Embodiment 2

[0028] A preparation method for a polyurethane elastomer used as an elevator counterweight guide shoe lining, comprising the following steps:

[0029] (1) Preparation of polyurethane prepolymer: 69 parts by mass of branched polytetrahydrofuran diol (brand PTG-L2000) with a molecular weight of 2000, 31 parts by mass of polycaprolactone diol (brand PCL220N) with a molecular weight of 2000, methanol Mix 1.0 parts by mass of base silicone oil (brand DM20000) and 2.0 parts by mass of fumed silica (brand HB615), heat to 120±5°C, evacuate until the residual pressure is less than 500Pa, keep warm for 2 hours, and then cool down to 55±3 ℃, slowly drop it into 35±3℃, 87 parts by weight of 2,4-toluene diisocyanate, control the dropping speed, and keep the temperature of the reaction mixture system between 60-70℃. After the dropwise addition, keep warm for 1.5 hours, then raise the temperature to 82±2°C and react for 2 hours; then conduct short-path distillation on the reaction mixture un...

Embodiment 3

[0032] A preparation method for a polyurethane elastomer used as an elevator counterweight guide shoe lining, comprising the following steps:

[0033] (1) Preparation of polyurethane prepolymer: 73 parts by mass of branched polytetrahydrofuran diol (brand PTG-L2000) with a molecular weight of 2000, 27 parts by mass of polycaprolactone diol (brand name CAPA2101A) with a molecular weight of 1000, methanol Mix 3.0 parts by mass of base silicone oil (brand DM30000) and 2.0 parts by mass of fumed silica (brand A200), heat to 120±5°C, evacuate until the residual pressure is less than 500Pa, keep warm for 2 hours, and then cool down to 55±3 ℃, slowly drop it into 35±3℃, 181 parts by weight of 2,4-toluene diisocyanate, control the dropping speed, and keep the temperature of the reaction mixture system between 60-70℃. After the dropwise addition, keep warm for 2.0 hours, then raise the temperature to 82±2°C and react for 2 hours; then perform short-path distillation on the reaction mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com