Leg structure of jumping robot

A robot and leg technology, applied in the field of the leg structure of jumping robots, can solve the problems of poor ability to jump obstacles, the robot does not have the ability to jump obstacles, and increase the safety risk of personnel, so as to achieve the effect of enhancing the ability to jump and jump obstacles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

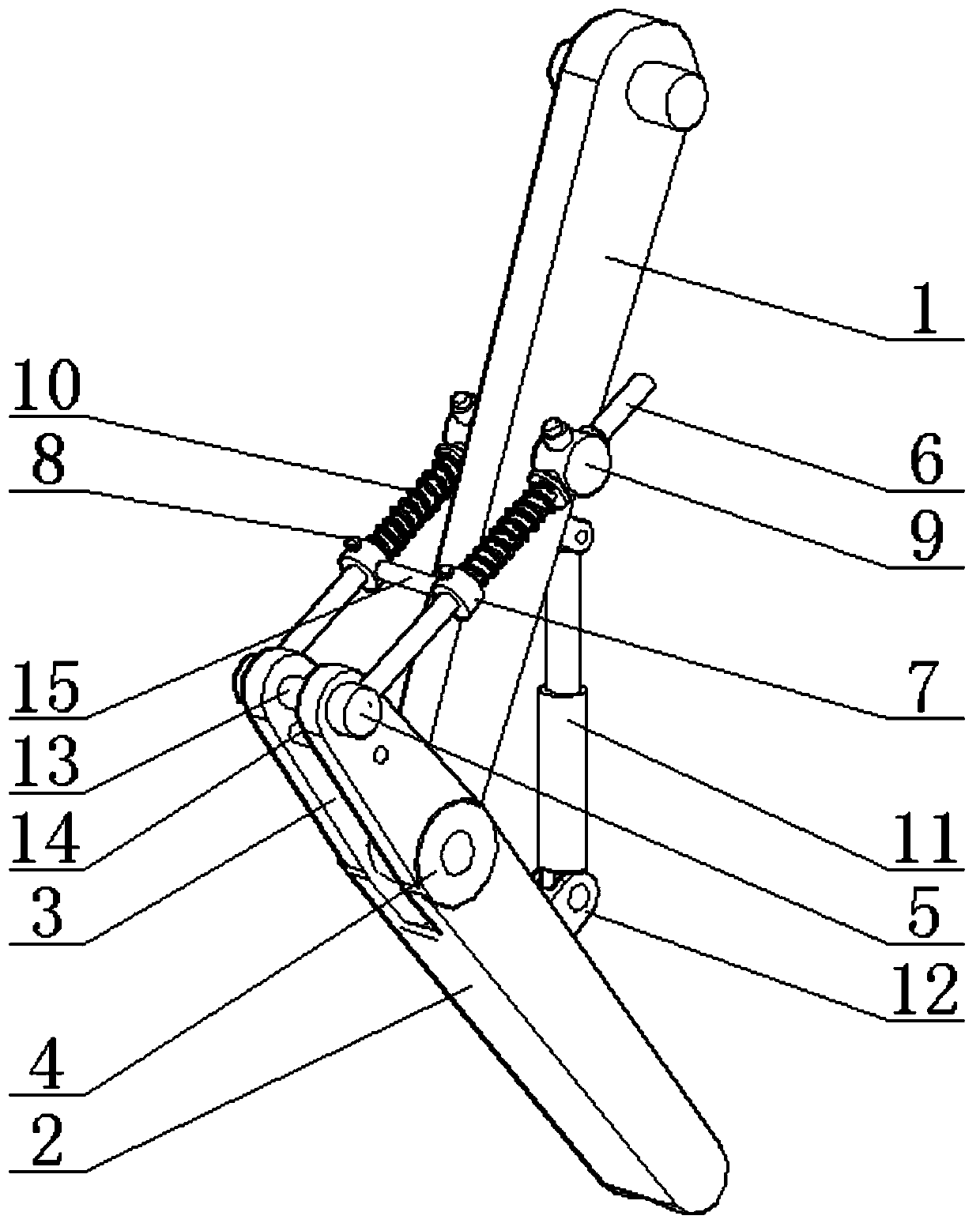

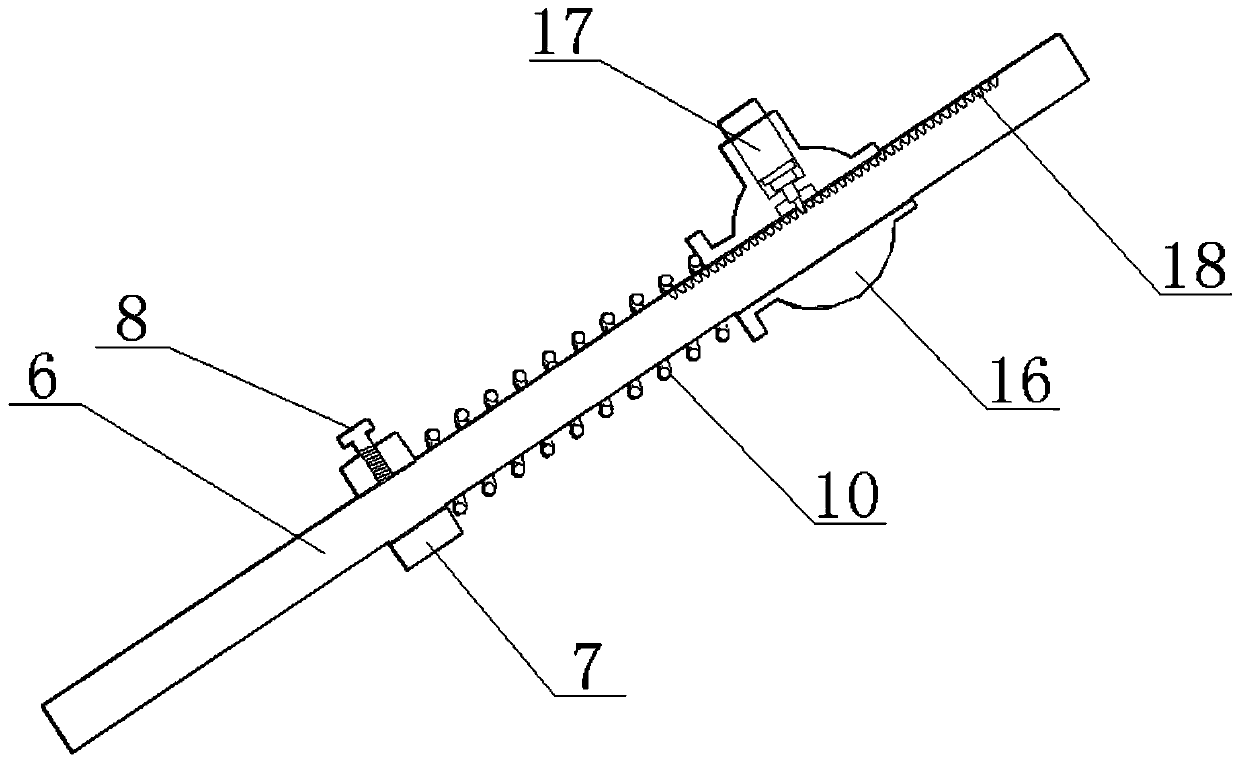

[0017] see Figure 1-2 , a leg structure of a jumping robot, comprising a mechanical thigh 1 and a mechanical lower leg 2, the upper middle part of the mechanical lower leg 2 is provided with a mounting groove 3, the bottom of the mounting groove 3 is provided with a mechanical joint 4, and the mechanical joint 4 moves with the bottom of the mechanical thigh 1 The connection is used for the bending activity between the mechanical thigh 1 and the mechanical lower leg 2. The outer side of the top of the mechanical lower leg 2 is relatively symmetrically installed with a movable block 5. The movable block 5 can be rotated and connected on the mechanical lower leg 2, and the outer surface of the movable block 5 is fixedly connected. There is a movable rod 6, the middle part of the movable rod 6 is socketed and connected with a movable sleeve 7, and the movable sleeve 7 is provided with a screw hole, and the inner thread of the screw hole is connected with a locking bolt 8, which is...

Embodiment 2

[0019] In the present invention, a support rod 13 is fixedly connected between the inner sides of the top ends of the installation grooves 3 , and a plurality of sets of connecting rods 14 are fixedly connected to the inner side of the installation groove 3 on one side of the support rods 13 to ensure the internal stability of the installation groove 3 .

[0020] A fixed rod 15 is detachably connected between the two groups of movable sleeves 7 to ensure the consistency of the positions of the two groups of movable sleeves 7 on the movable rod 6, thereby ensuring that the potential energy of the two groups of tension springs 10 is approximately the same.

[0021] The self-locking device 9 includes a lock sleeve 16 and an electronic lifting rod 17. A sleeve hole is provided through the middle of the lock sleeve 16, and the movable rod 6 is slidably connected to the inside of the sleeve hole. Rod 17.

[0022] The movable rod 6 located at one end of the self-locking device 9 is p...

Embodiment 3

[0026] The working principle of the present invention is: when working, the electric telescopic rod 11 contracts, making the mechanical thigh 1 and the mechanical lower leg 2 bend and the mechanical thigh 1 and the mechanical lower leg 2 rotate relatively through the mechanical joint 4, and the mechanical thigh 1 and the mechanical lower leg 2 The included angle becomes smaller, and at the same time, the distance between one end of the movable block 5 and the self-locking device 9 increases, thereby increasing the distance between the movable sleeve 7 and the self-locking device 9. After the distance between the two increases, the pulling force The spring 10 is elongated, so that the tension spring 10 stores elastic potential energy. In addition, the movable rod 6 slides in the direction of the movable sleeve 7 in the lock sleeve 16. When the mechanical thigh 1 and the mechanical lower leg 2 bend to the set critical point, the electric telescopic rod 11 stops. shrink, and at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com