Unmanned forklift motion control method and unmanned forklift assembly motion control method

An unmanned forklift and motion control technology, applied in non-electric variable control, vehicle position/route/height control, transportation and packaging, etc., can solve the problems of cumbersome process and long time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

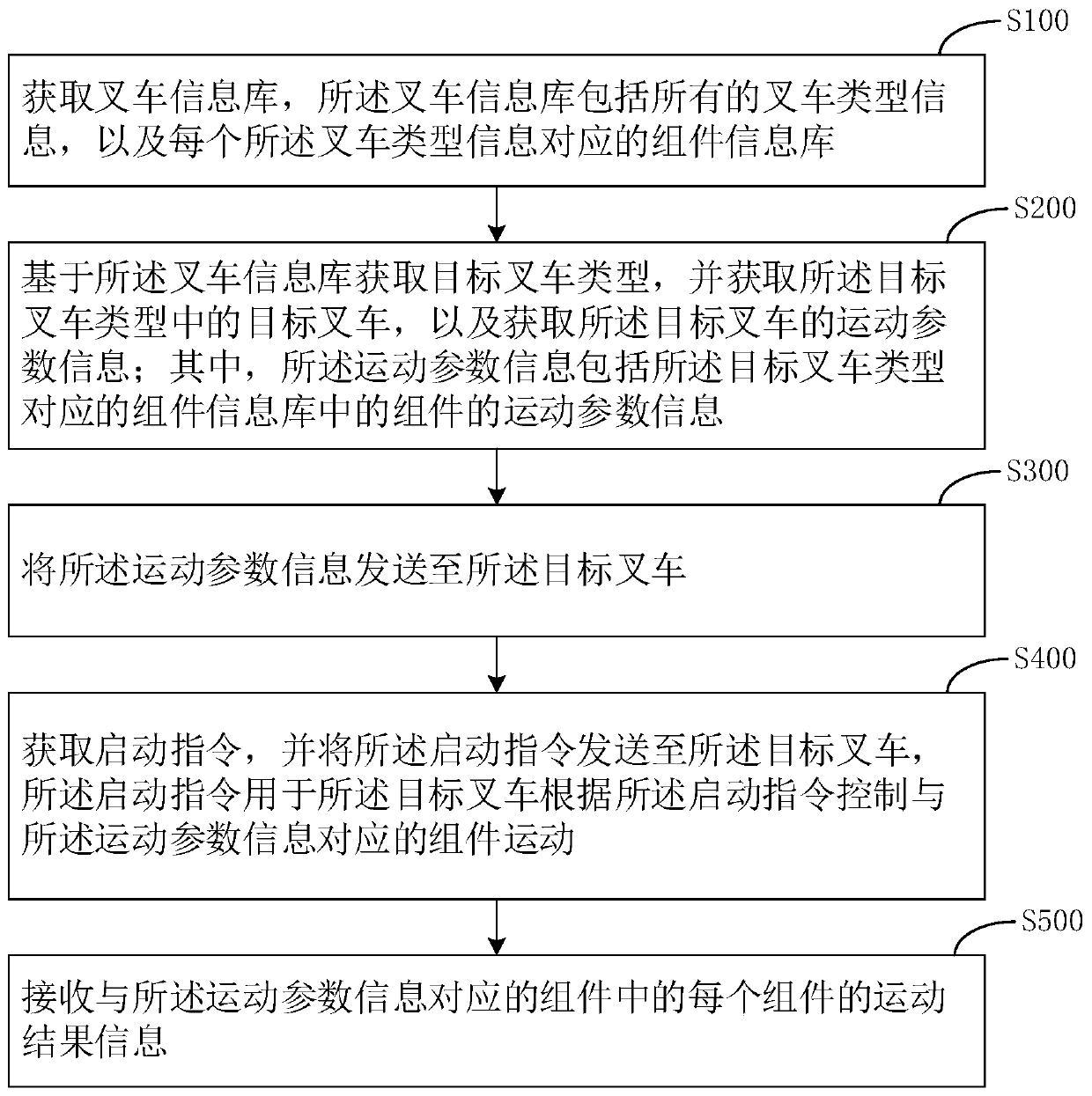

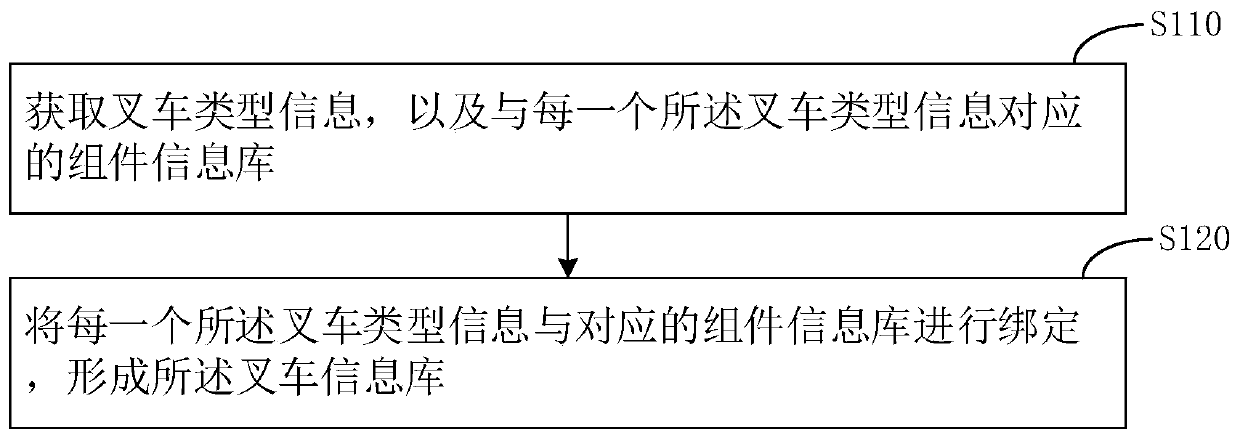

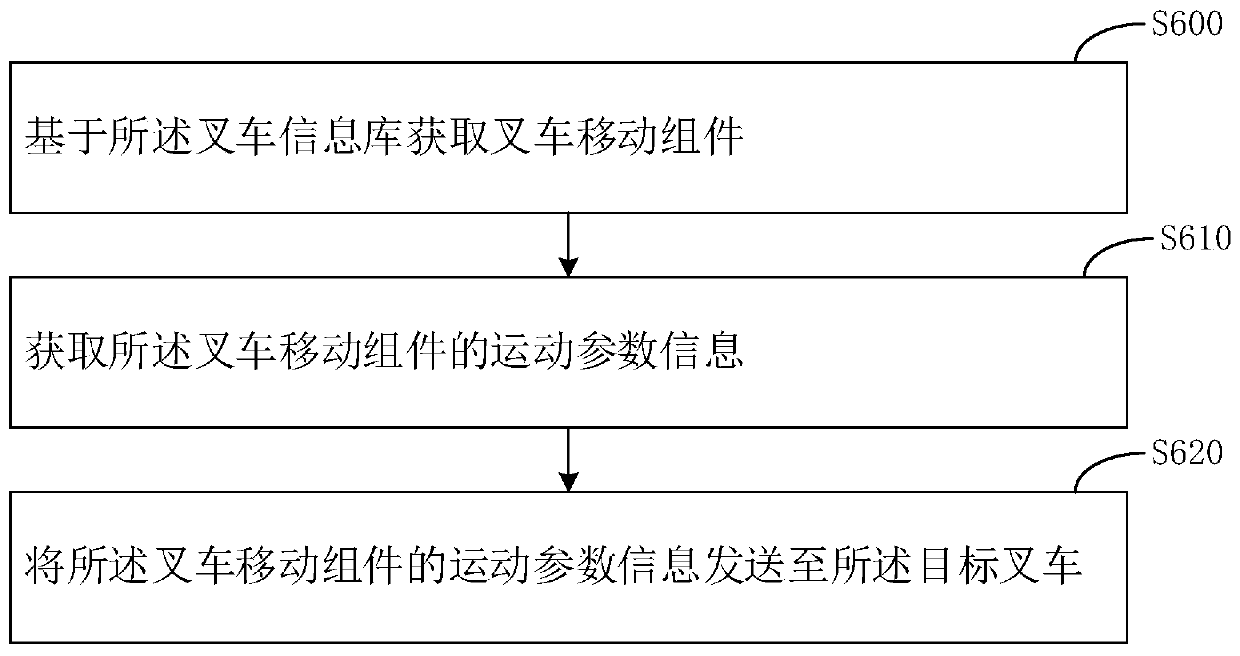

Method used

Image

Examples

Embodiment Construction

[0065] With the development of society, especially the advancement of science and technology, it has greatly promoted the rapid development of social productivity, especially the acceleration of industrialization and informationization. Among them, electric forklifts, as a common industrial handling vehicle, are often used for loading and unloading, stacking and short-distance transportation of palletized goods, and are widely used in ports, stations, airports, freight yards, factory workshops, warehouses, etc. occasion. It can be understood that electric forklifts include many components, such as joysticks, forks, pick rods and so on. In the actual operation of the electric forklift, it is necessary to control the operation of the components in the electric forklift. However, when controlling the operation of the electric forklift and the components in the electric forklift in the traditional solution, the staff needs to control different types of electric forklifts, which w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com