Auxiliary mounting tool for shaft sleeve ring and method for mounting shaft sleeve ring

A technology for installing tools and shaft sleeves, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve problems such as low efficiency, inconvenient streamlined operations, and inability to set shaft sleeve rings, so as to improve efficiency and avoid secondary Effect of cleaning and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

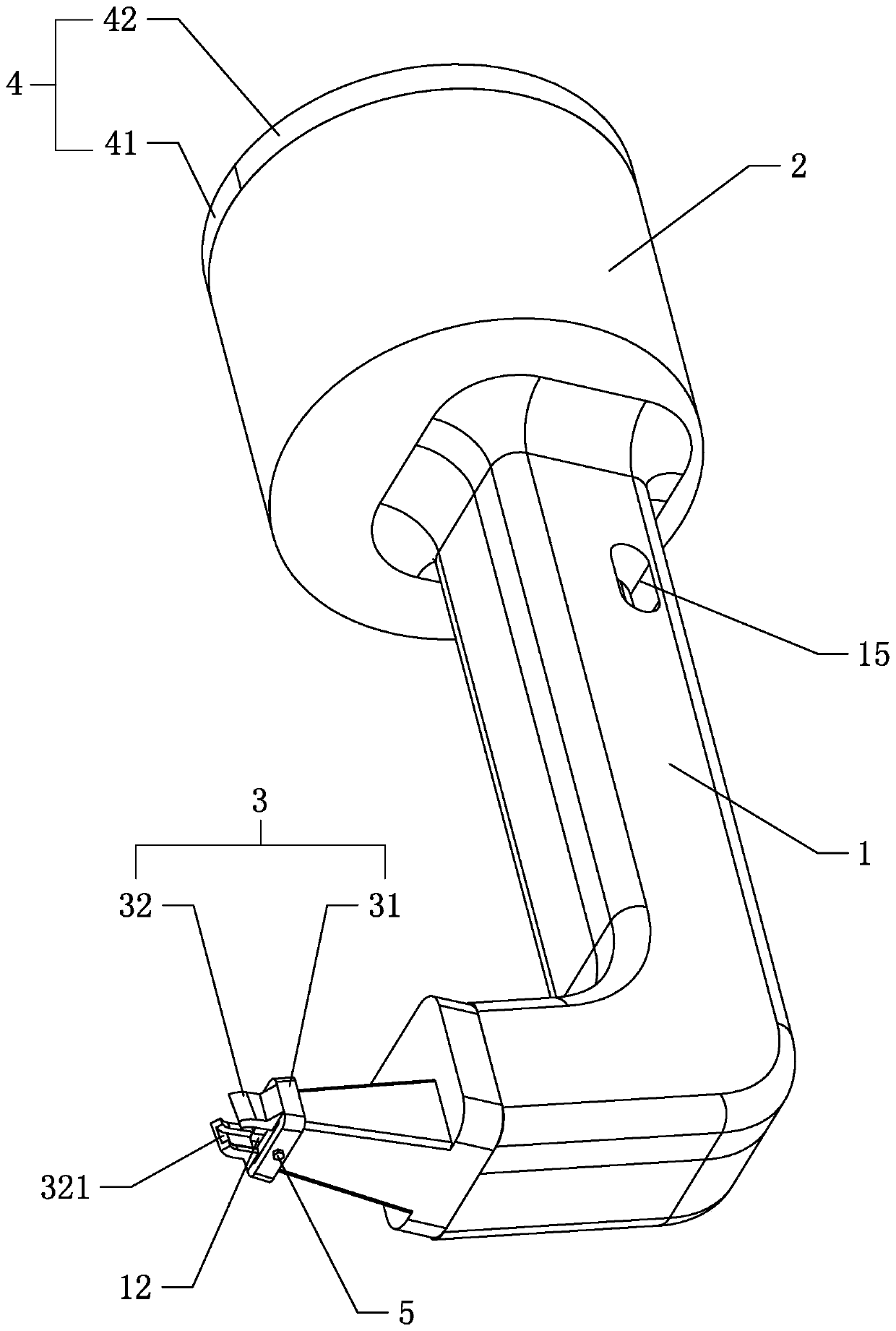

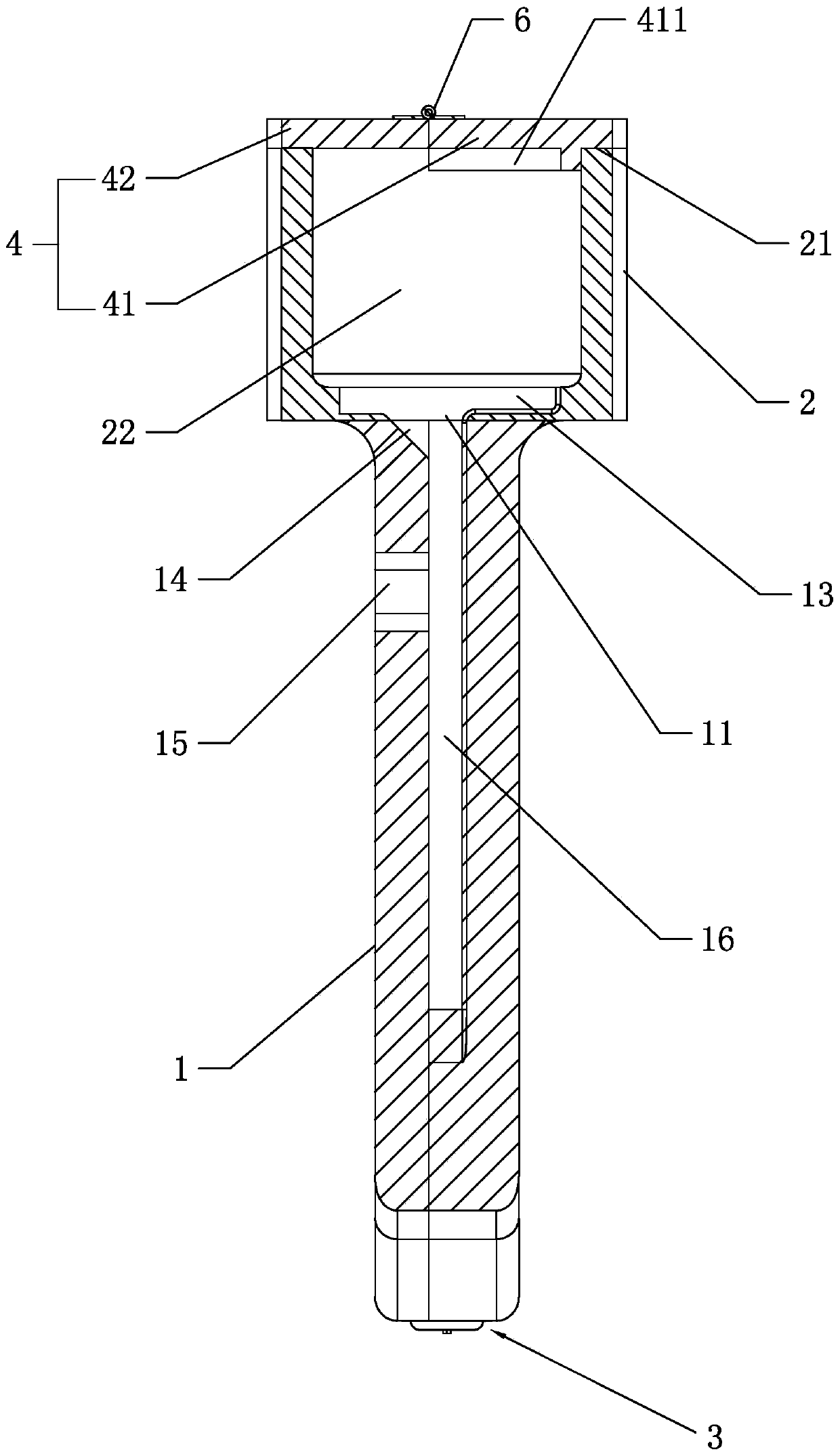

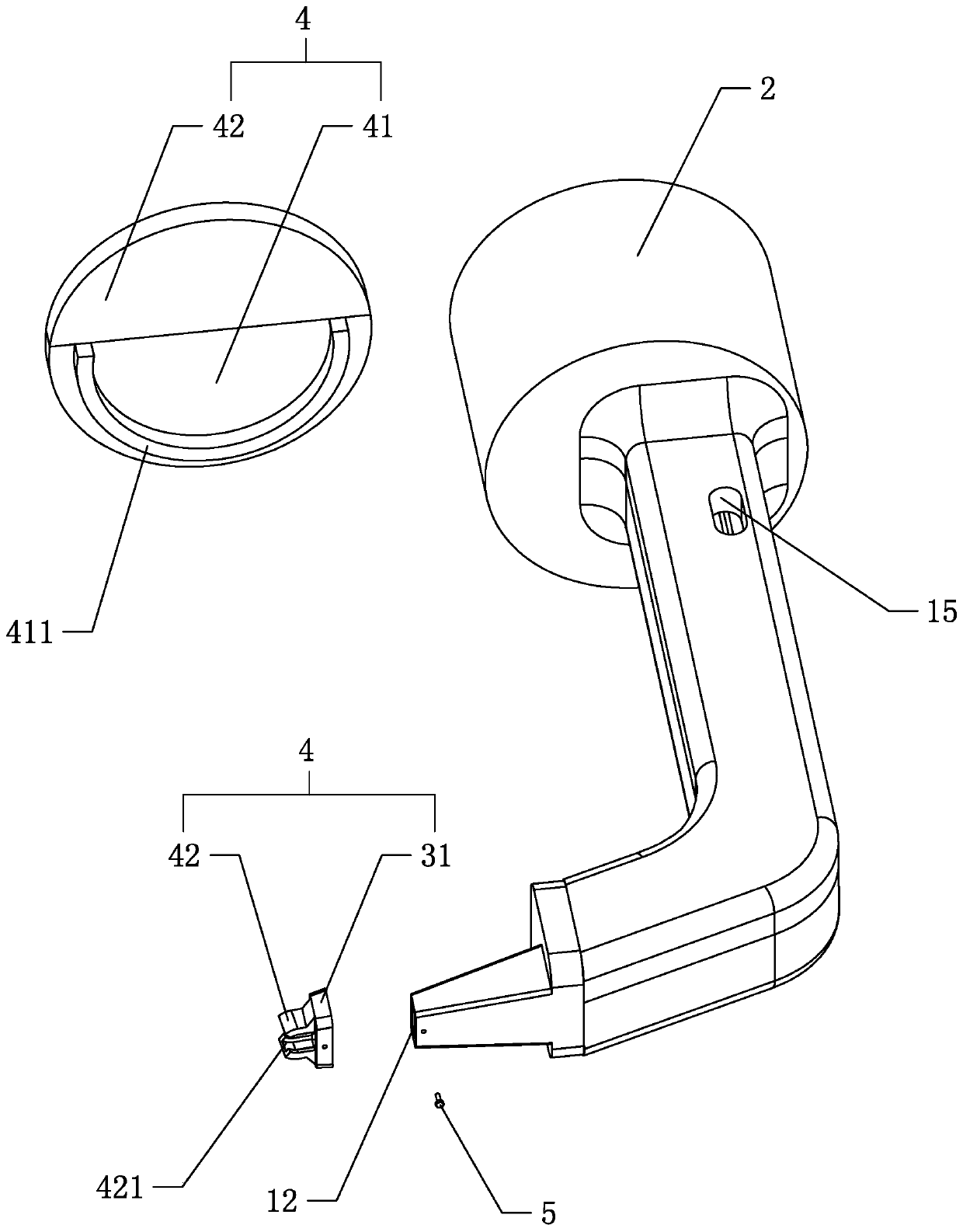

[0041] Example 1: Combining figure 1 and figure 2, is an auxiliary installation tool for shaft sleeve rings disclosed in the present invention, which includes an L-shaped tube body 1, and a track 16 for accommodating the ring body is arranged inside the tube body 1, and the two ends of the tube body 1 are respectively The track 16 is connected to the feed port 11 and the discharge port 12. The length of the long side on the cross section of the track 16 is slightly greater than the outer diameter of the ring body, and the length of the short side is less than the outer diameter of the ring body but slightly greater than the thickness of the ring body. It is convenient for the ring body to slide smoothly from the feed port 11 to the discharge port 12. Preferably, the included angle of the pipeline is 100° to 120°, so that the ring body can be subjected to the gravity of the ring body from the feed port 11 , slide out from the discharge port 12 along the track 16, and enter th...

Embodiment 2

[0051] Embodiment 2: a method for installing a shaft collar disclosed by the present invention, comprising the following steps:

[0052] Step 1, put the ring body in the container 2: turn the second cover plate 42, open the opening 21 of the container 2, put the ring body into the container 2, turn the second cover plate 42, close the opening 21 of the container 2.

[0053] Step 2: The track 16 is full of rings: Press and hold the cover 4, shake the container 2, and you can see the rings in the track 16 along the observation port 15. When the track 16 is full of rings, stop shaking the container 2 .

[0054] Step 3: Install the ring body on the shaft body: the ring body on the jaw 32 is sleeved on the shaft body from one end of the shaft body, and the pipe body 1 is pulled along the radial direction of the shaft body, so that the ring body produces a force on the jaw 32 force, the jaws 32 produce elastic deformation, the ring body is separated from the jaws 32 at the port of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com