Guide component and guide device

A technology of guiding components and guiding devices, applied in transportation and packaging, elevators, non-rotational vibration suppression, etc., can solve problems such as inability to achieve vibration reduction effects, and achieve the effect of eliminating vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

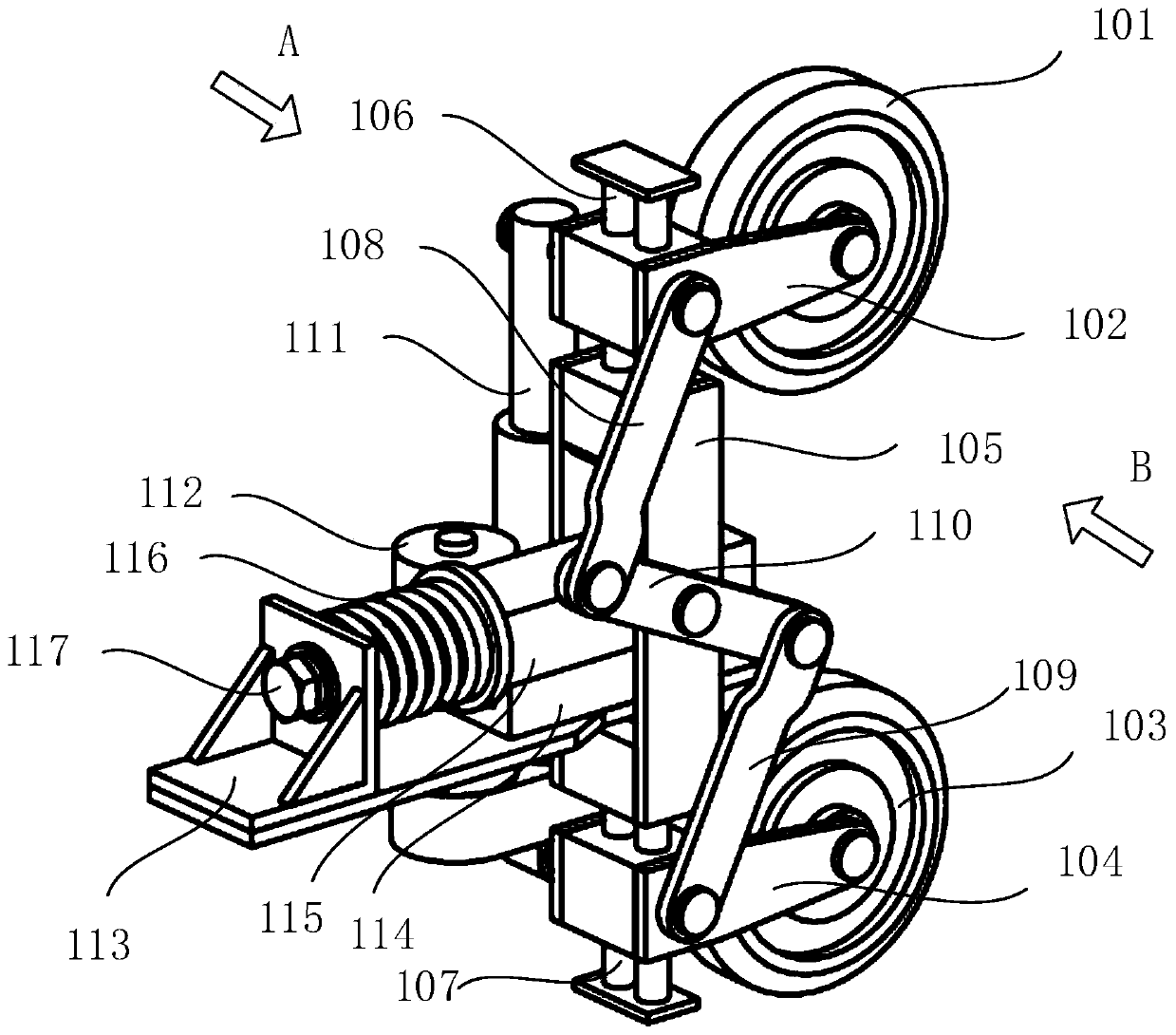

[0060] Such as Figure 1-4 As shown, in the guide assembly 1, the first roller 101 is rotatably connected to the first mount 102 through the roller shaft, the second roller 103 is rotatably connected to the second mount 104 through the roller shaft, and the first mount 102 is connected to the first The sliding rod 106 cooperates, and the first mounting base 102 can slide along the axial direction of the first sliding rod 106, and the second mounting base 104 cooperates with the second sliding rod 107 and can also slide along the axial direction of the second sliding rod 107 . The first mount 102 is relatively rotatably connected to one end of the first connecting rod 108 and the moving part 111 of the actuator through the roller mount shaft, and the second mount 104 is simultaneously connected to the second connecting rod 109 through the roller mount shaft. One end is relatively rotatably connected to the fixed part 112 of the actuator. The moving part 111 of the actuator ca...

Embodiment 2

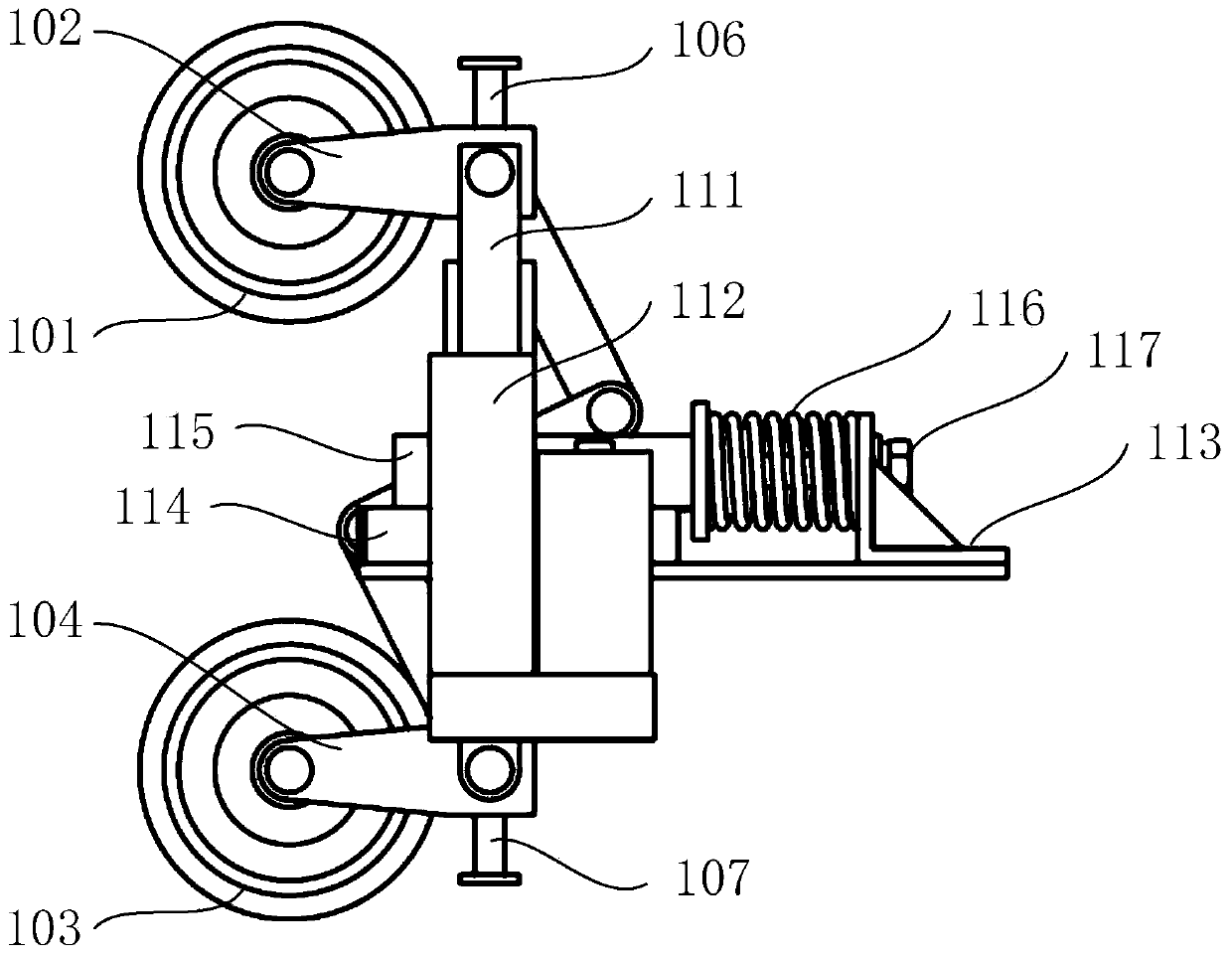

[0063] Such as Figure 5-6 As shown, in this embodiment, the guide assembly 1 is different from the first embodiment in the composition of the connection device and the actuator. The first roller 101 and the second roller 103 are respectively installed through the first mounting seat 102 and the second mounting seat 102 of the roller shaft. Block 104 is connected. The first mount 102 cooperates with the first slide bar 106, and the first mount 102 can slide along the axial direction of the first slide bar 106, and the second mount 104 cooperates with the second slide bar 107 and can also slide along the first slide bar 107. The two sliding rods 107 slide axially. Meanwhile, the first mounting base 102 is fixedly connected with the first moving part 121 of the actuator, and the second mounting base 104 is fixedly connected with the second moving part 122 of the actuator. One end of the first slide bar 106 is connected to the swing arm 105 , and the other end is fixedly connec...

Embodiment 3

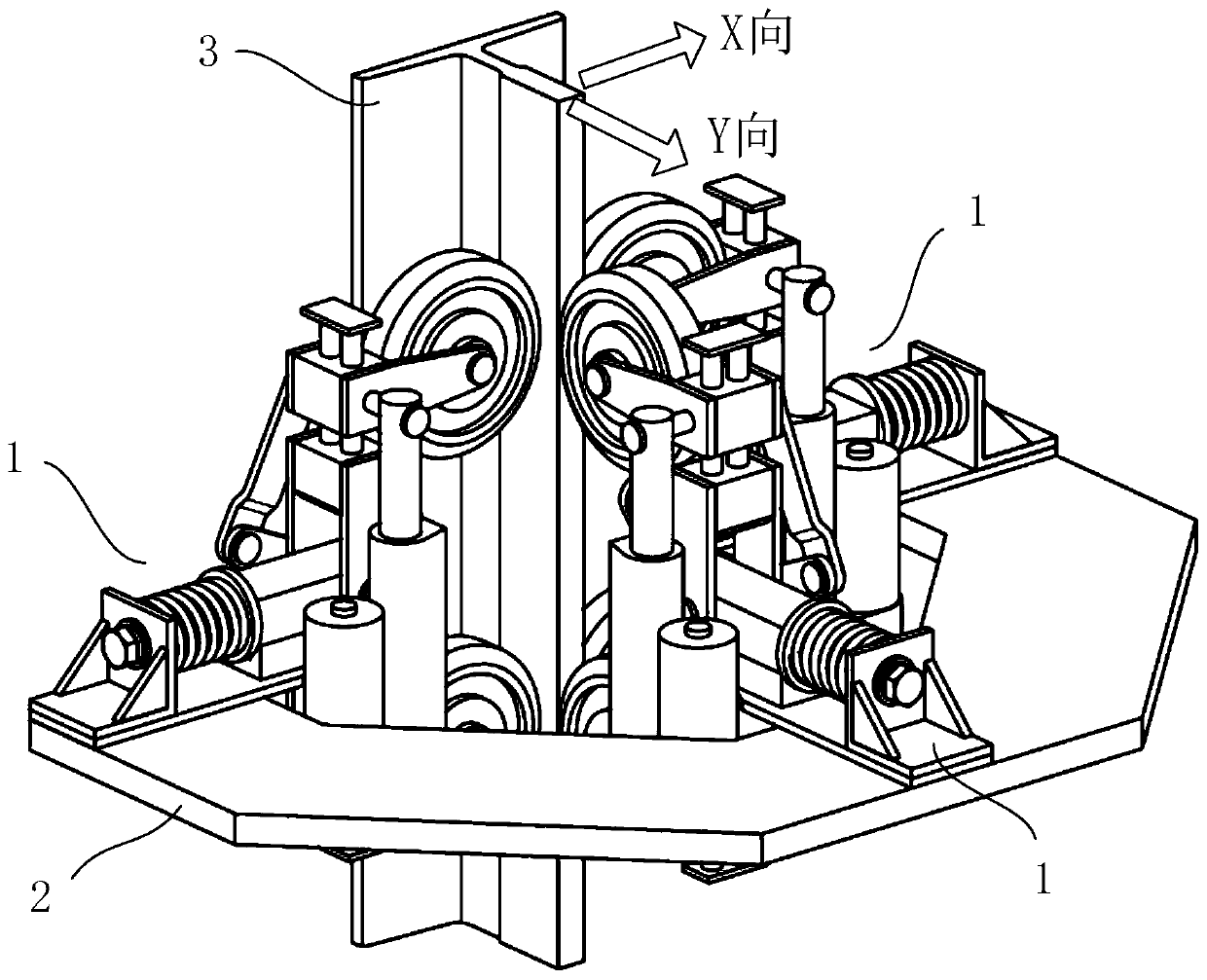

[0066] Such as Figure 1-6 As shown, a guide device is disclosed in this embodiment, and the guide device is mainly composed of three sets of guide assemblies 1 and guide rails 3 installed on the guide mounting plate 2 . Wherein, the guide rail 3 includes a first guide surface, a second guide surface and a third guide surface, the first guide surface is parallel to and opposite to the second guide surface, and the third guide surface is perpendicular to the first guide surface and the second guide surface. The three sets of guide components 1 are respectively matched with the three guide surfaces. At the same time, in order to minimize the installation space, the first guide component 1 and the third guide component 1 of the guide device are identical, and the second guide component 1 is the same as the first two sets of guide components. 1 The components of the components are the same, and only the assembly structure is mirror symmetrical.

[0067] Before the guide device is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap