Transmission device with high stability of three-dimensional measuring machine

A technology of a three-coordinate measuring machine and a transmission device, which is applied in the directions of measuring devices and instruments, and can solve the problems such as the large influence of the transmission device on the measurement accuracy, the large vibration of the belt, and the vibration of the three-coordinate measuring machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

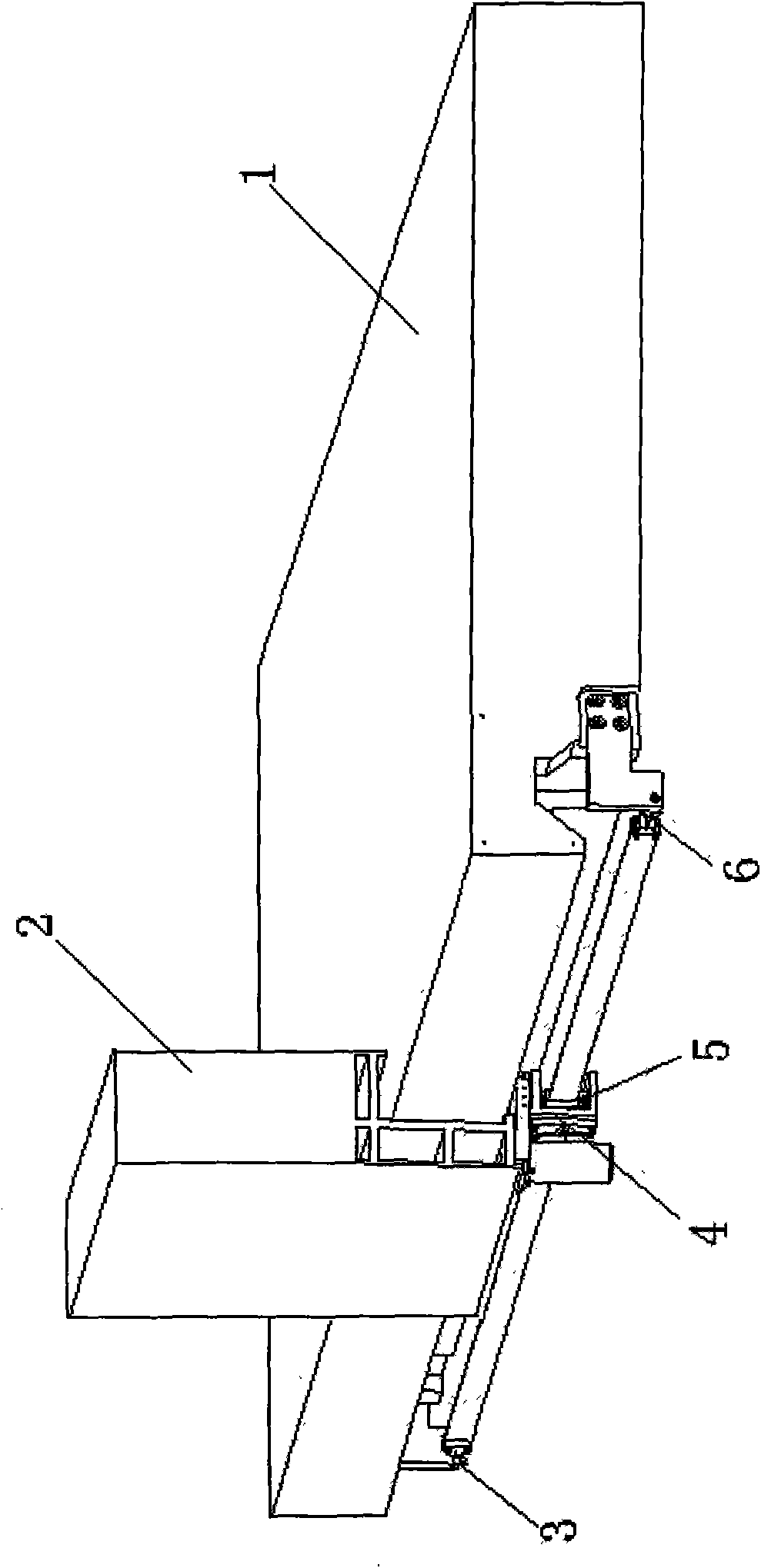

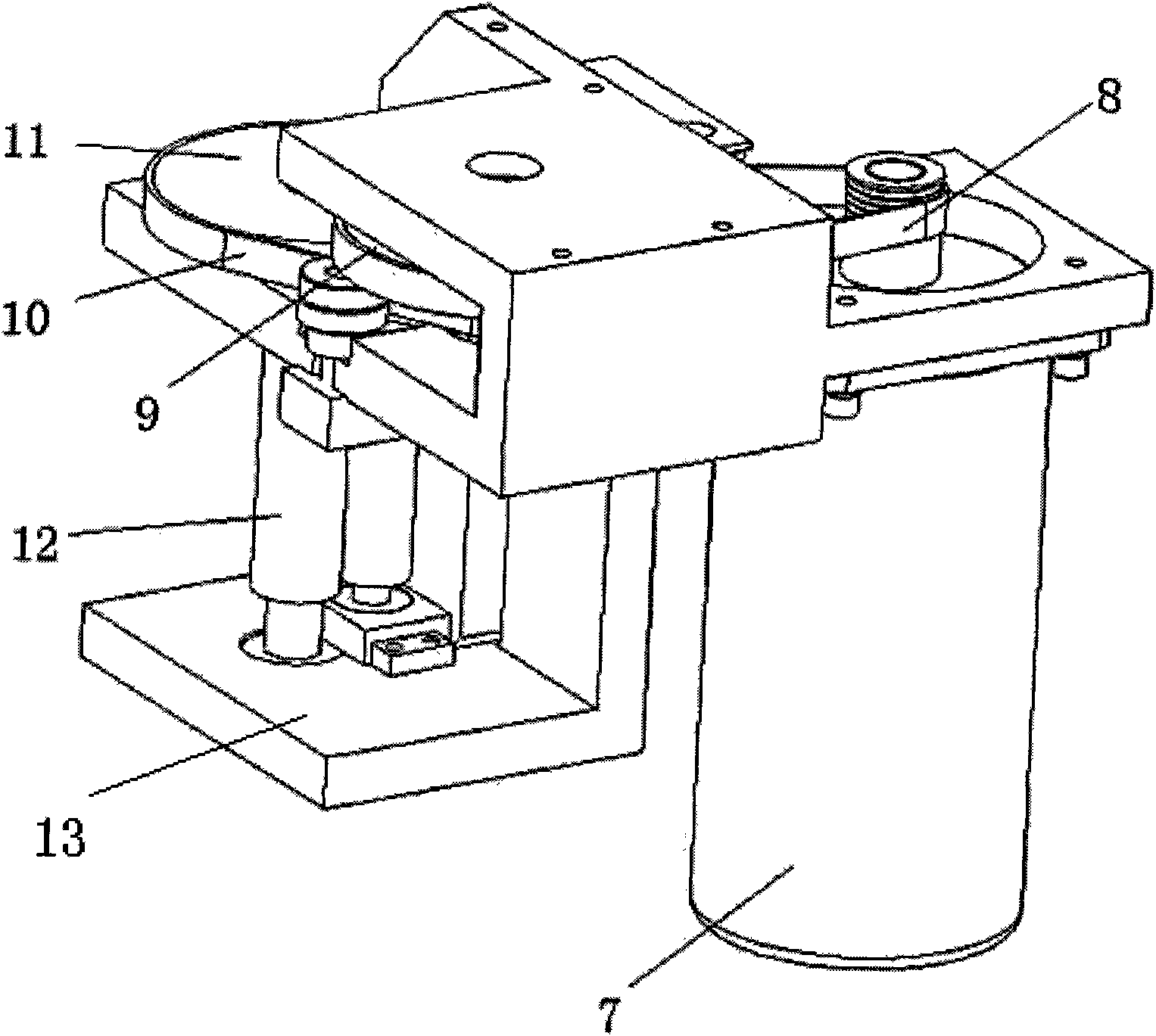

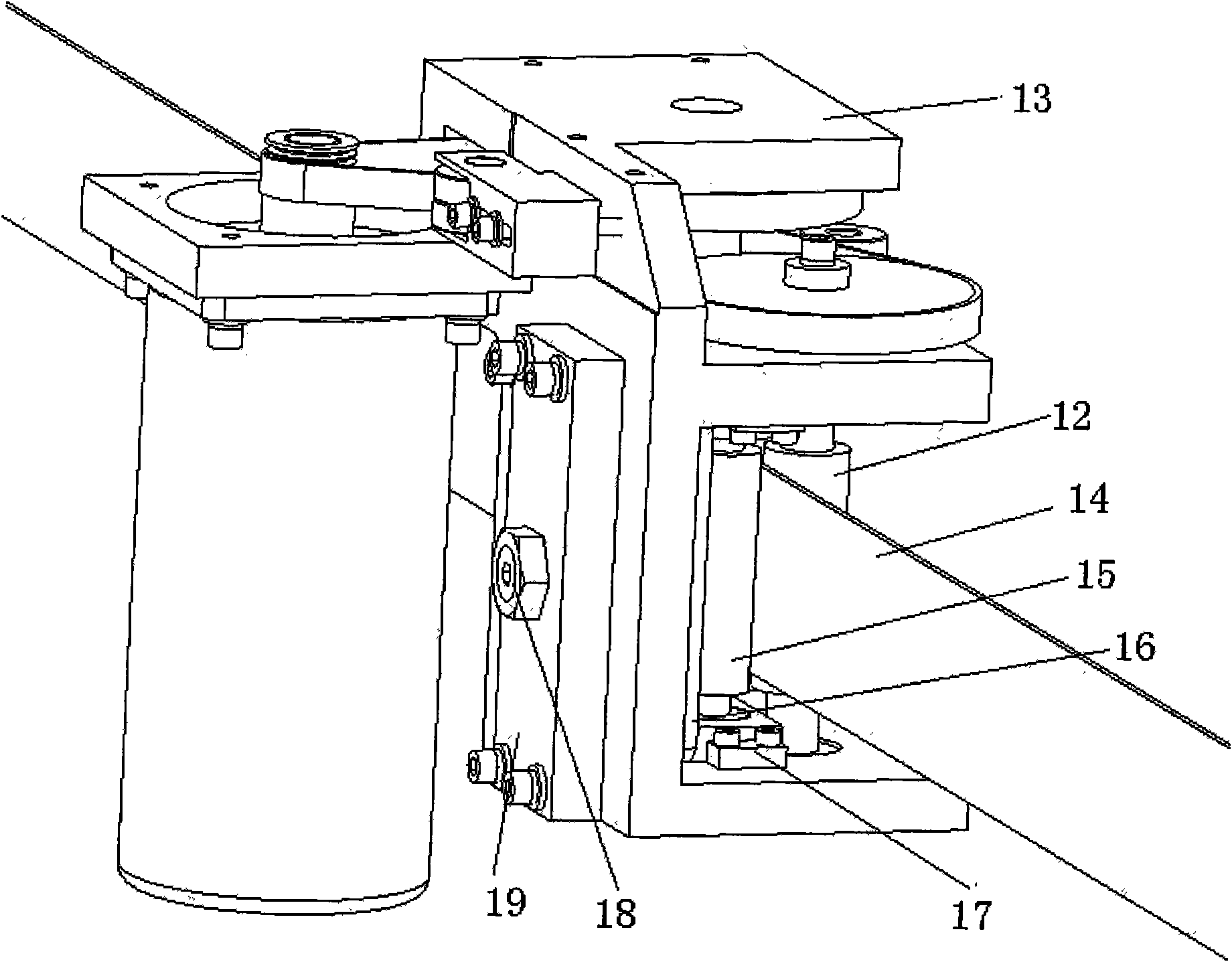

[0011] Such as Figure 1-4 , the technical solution of the present invention includes the deceleration device 4 fixed on the frame 13, the clamping device 5, and is characterized in that it also includes a shock absorbing device composed of two parts, the front shock absorbing device 3 and the rear shock absorbing device 6, the above-mentioned The damping device comprises an adapter 23 fixed at the two ends of the steel band 14 and a damping plate 21 fixed at the other end of the adapter 23, and the other end of the damping plate 21 is fixed on the fixing plate 20 via a screw 22. The plate 20 is fixed on the measuring platform 1, the driving roller 12 and the driven roller 15 of the clamping device 5 clamp the steel belt 14, the driven roller 15 is supported on the driven block 16, and the driven block 16 is pressed Tighten plate 19 and nut 18 to adjust the distance between driving roller 12 and driven roller 15, and guide block 17 is fixed on frame 13 chassis to limit driven ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap