A free piston Stirling machine device

A technology of piston and small piston is applied in the field of free piston Stirling machine, which can solve the problems of difficult processing, severe system vibration and high process cost, and achieve the effect of reducing processing difficulty and eliminating system vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

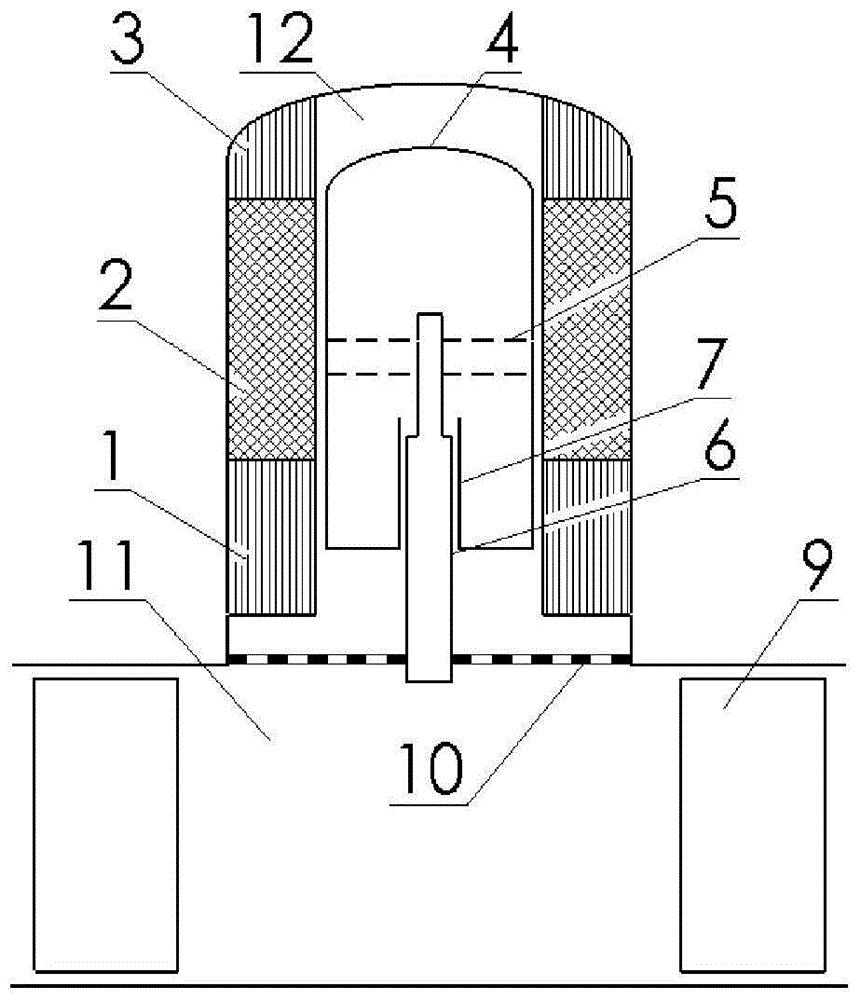

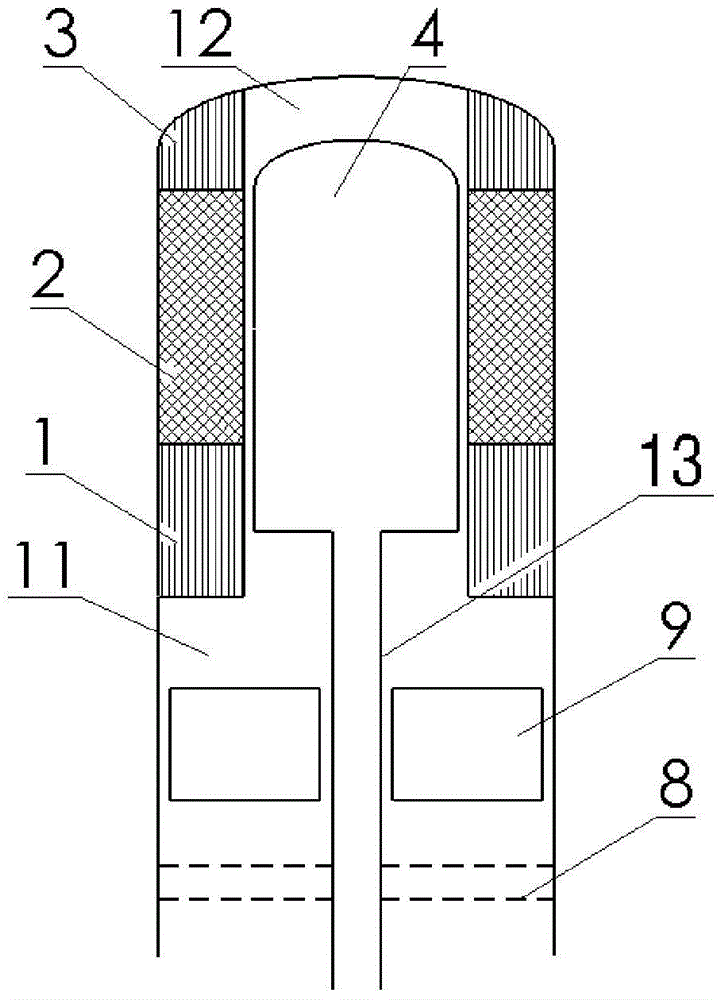

[0034] The specific embodiments of the invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

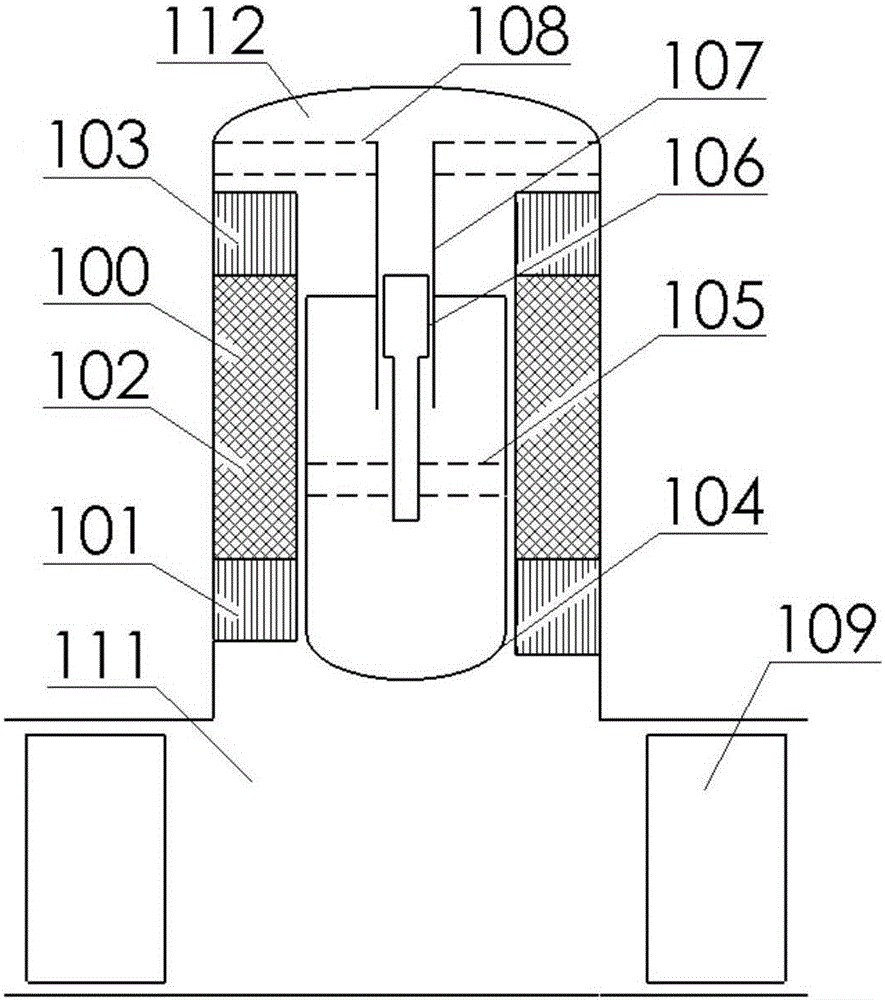

[0035] Figure 4 A schematic structural diagram of a free-piston Stirling machine device provided in this embodiment is shown, including an ejector 104, a small piston 106, a housing 100, an elastic support structure 108, and a room temperature heat exchanger 101;

[0036] The small piston 106 is arranged in the cylinder of the displacer 104 along the central axis of the displacer 104, and there is a gap between the cylinder of the displacer 104;

[0037] The ejector 104 is disposed in the housing 100;

[0038] The room temperature heat exchanger 101 is arranged between the casing 100 and the ejector 104, is in contact with the casing 100, and has a gap with the ejector 104...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap