Grinding wheel balance vibration absorption device and method based on eap drive

A grinding wheel and balancing technology, which is applied in the field of grinding processing, can solve problems such as the inability to guarantee the accuracy of vibration signals, increase the complexity of the adjustment system, and interfere with signal sensor acquisition, so as to reduce rotor frequency interference, avoid untimely processing, and improve position and the effect of the parameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

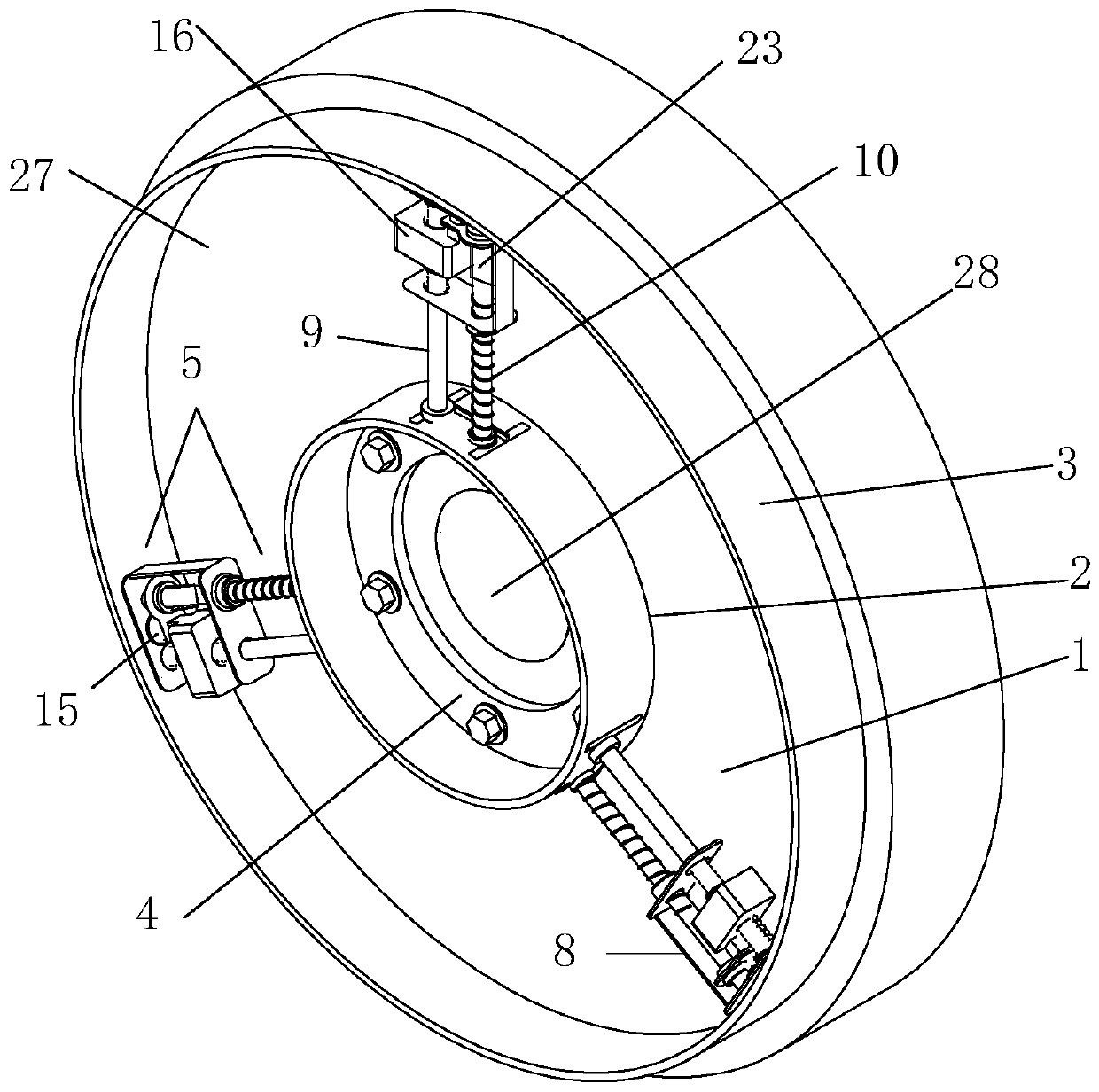

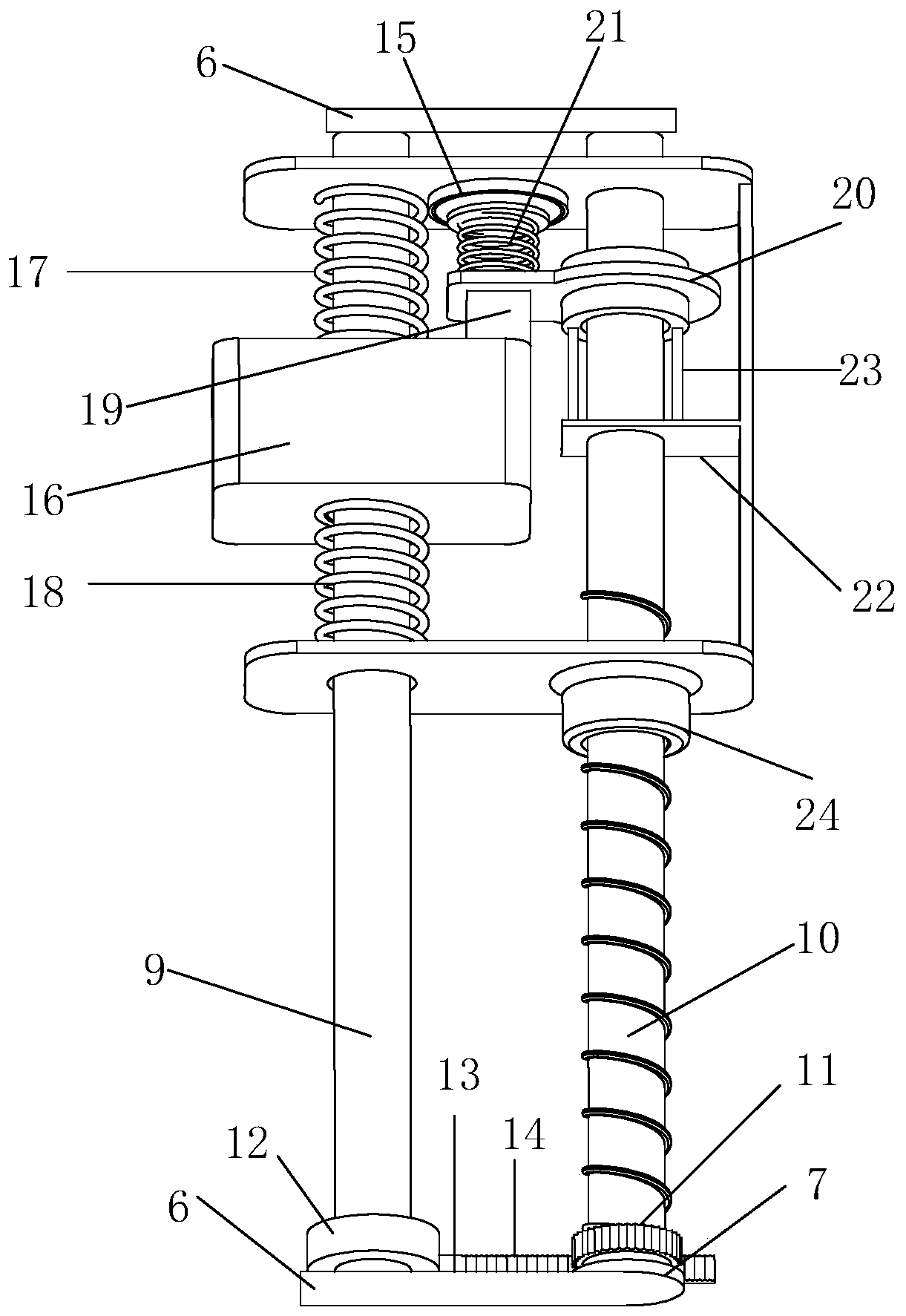

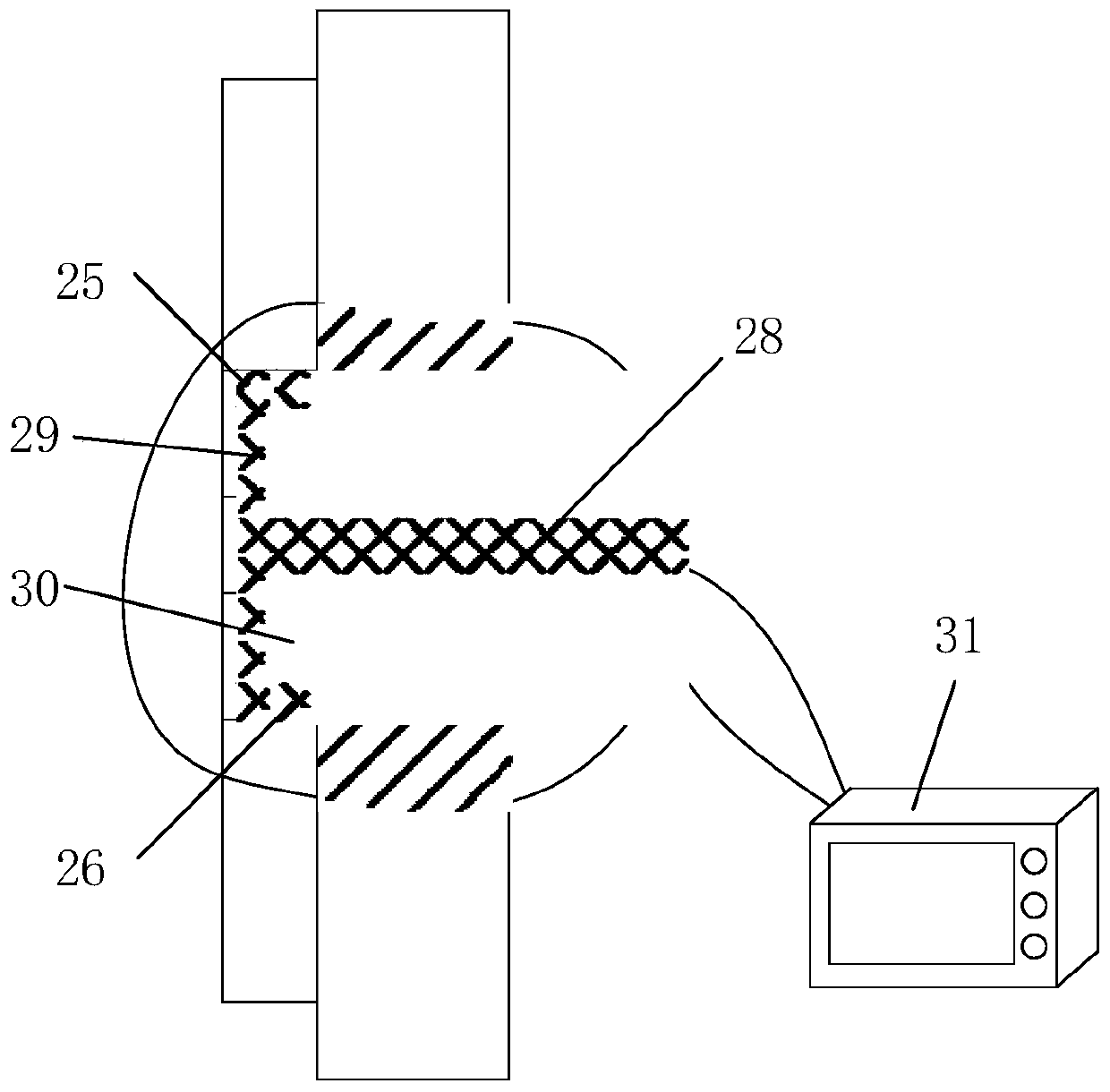

[0030] according to Figure 1-3 As shown, the present invention provides a grinding wheel balance vibration-absorbing device driven by EAP, and the technical scheme is as follows:

[0031] include:

[0032] The outer cover 1, the inner and outer edges of the outer cover 1 are respectively provided with an inner ring 2 and an outer ring 3 of concentric circle structure, the outer cover 1 is the outer container of the grinding wheel balance vibration absorbing device, and the outer surface of the outer cover 1 is sealed and clamped with a transparent panel 27, The transparent panel 27 is an acrylic plate or plexiglass, and the transparent panel 27 acts as a seal to prevent external disturbances from affecting the structure of the grinding wheel balance vibration-absorbing devi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap