A kind of heat-resistant phenolic airgel and preparation method thereof

An airgel and phenolic technology, applied in the field of heat-resistant phenolic airgel and its preparation, can solve the problems of high raw material prices, inconvenient application and promotion, and complicated preparation process, and achieve high network skeleton strength, low price, and easy operation Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Step 1, the synthesis of boron phenolic resin: phenol, formaldehyde, boric acid are added in the reactor in the ratio of 1:1.5:0.3 by molar ratio, then add catalyst zinc oxide, wherein the amount of zinc oxide is 1% of phenol weight, Raise the temperature to 90°C, react for 6 hours, and then distill and dehydrate under reduced pressure to obtain a boron-modified phenolic resin.

[0039] Step 2: fully mix the boron-modified phenolic resin, sulfuric acid, and ethanol in a ratio of 100:10:75 by weight to obtain a boron-modified phenolic resin ethanol solution.

[0040] Step 3: Treat the boron-modified phenolic resin ethanol solution at 60° C. for 24 hours under airtight conditions to obtain a phenolic wet gel.

[0041] Step 4, drying the phenolic wet gel at 50° C. under normal pressure for 24 hours, and then drying at 80° C. under normal pressure for 36 hours to obtain the final heat-resistant phenolic aerogel.

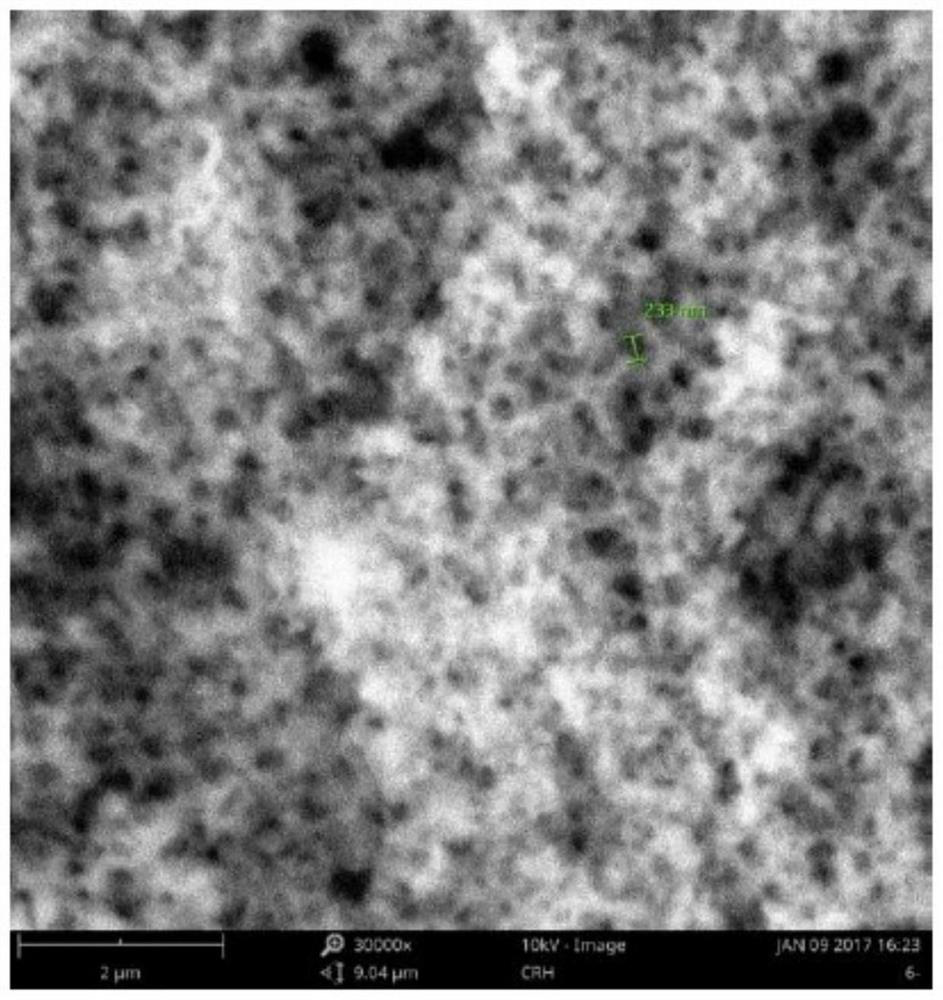

[0042] The heat-resistant phenolic airgel has a density of ...

Embodiment 2

[0044]This example is basically the same as Example 1, except that the boron-modified phenolic resin, sulfuric acid, and ethanol are fully mixed and evenly mixed in a weight ratio of 100:5:100.

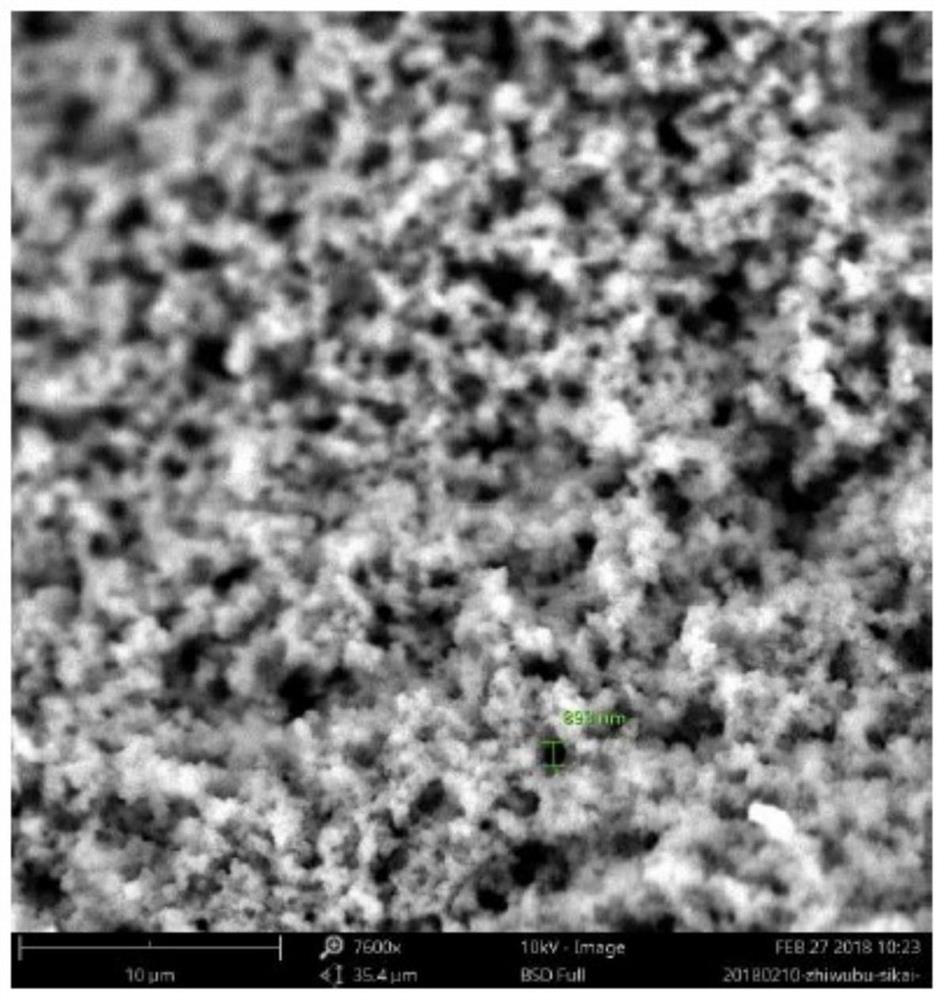

[0045] The density of the heat-resistant phenolic aerogel obtained is 0.41g / cm , and the aperture is 500nm-1 μm (see figure 2 ), the residual weight rate is 56.5%.

Embodiment 3

[0047] This embodiment is basically the same as Embodiment 1, except that the molar ratio of phenol, formaldehyde, and boric acid is 1:1.8:0.2; the amount of zinc oxide is 1.5% of the phenol weight; boron modified phenolic resin, sulfuric acid, ethanol The weight ratio is 100:10:200 and mixed well; the boron-modified phenolic resin ethanol solution is treated under airtight conditions at 60°C for 48 hours; the phenolic wet gel is dried at 50°C under normal pressure for 48 hours, and then dried at 80°C Press dry for 36 hours to obtain the final heat-resistant phenolic airgel.

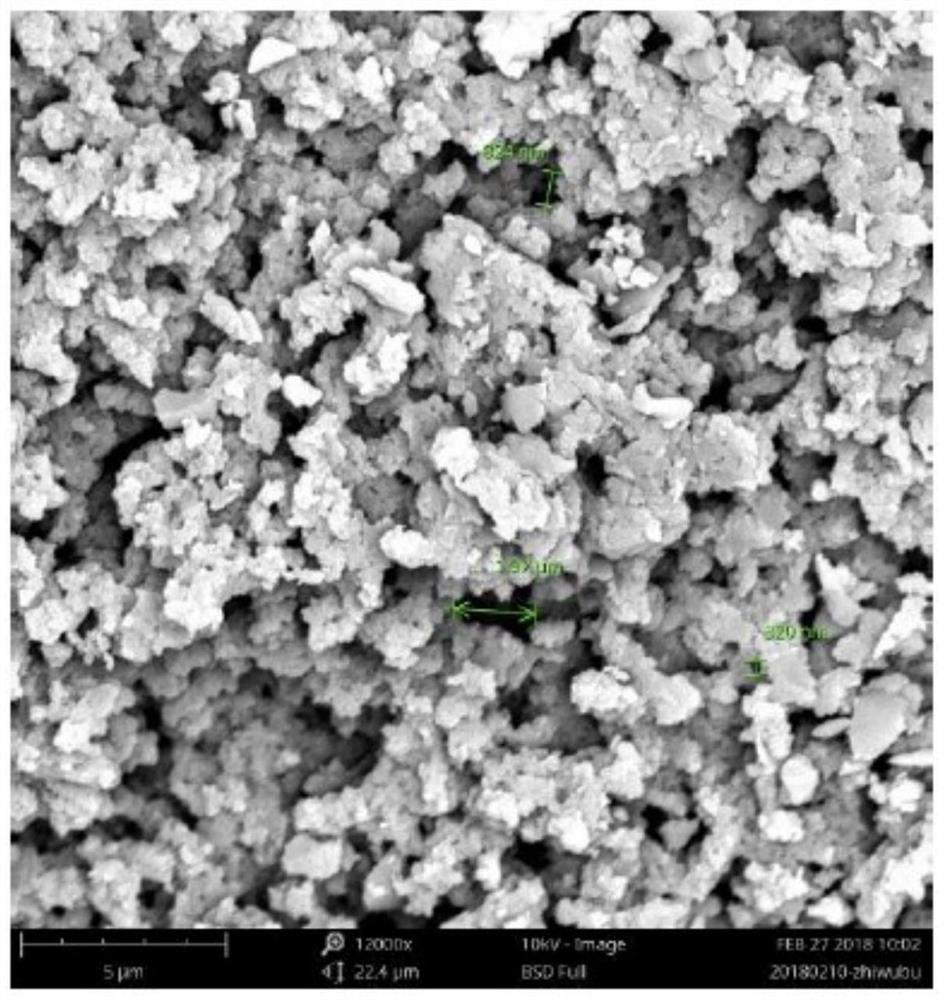

[0048] The density of this phenolic airgel is 0.28g / cm3, and aperture is 1-2 μm (referring to image 3 ), the residual weight is 54.5%.

[0049] In summary, the present invention adopts sol-gel-normal pressure drying process to prepare heat-resistant phenolic airgel, and through boron modification, the obtained phenolic airgel has the advantages of high heat resistance, high network skeleton strength, e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com