A method for on-line monitoring of converter oxygen jet effect

A jet and oxygen technology, applied in measuring devices, manufacturing converters, measuring fluid pressure, etc., can solve problems such as inability to accurately determine the melt loss of nozzles, early off-line of qualified nozzles, and extended use of nozzles, and achieve stable results and real-time data. The effect of tracking and increasing the number of furnaces used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

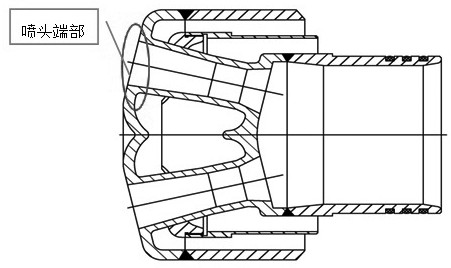

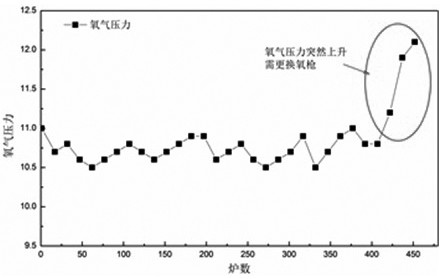

[0028] The oxygen lance nozzle is used for the first time. The design standard oxygen pressure of the oxygen lance nozzle is 1.07Mpa, and the design standard flow rate is 45000m3 / h.

[0029] Set the first threshold to 1.12 Mpa, and the second threshold to 1.03 Mpa.

[0030] The test is carried out at the stage of slag splashing to protect the furnace when it goes online. Nitrogen blowing with a flow rate of 45000m3 / h is stable and lasts for 40S, during which the actual pressure is P 0 ´=1.08Mpa, between the first threshold and the second threshold, which meets the design requirements, and the oxygen lance is normally used online.

Embodiment 2

[0032] The oxygen lance nozzle is in normal use. The design standard oxygen pressure of the oxygen lance nozzle is 1.07Mpa, and the design standard flow rate is 45000m3 / h.

[0033] Set the first threshold to 1.12 Mpa, and the second threshold to 1.03 Mpa.

[0034] The test is carried out at the stage of slag splashing for furnace protection. Nitrogen blowing with a flow rate of 45000m3 / h is stable for 30S, during which the actual pressure is P 0 ´=1.15Mpa, exceeding the first threshold, the end of the nozzle is severely worn, the jet flow is unstable, the oxygen lance is stopped, and it must be replaced offline.

Embodiment 3

[0036] The oxygen lance nozzle is in normal use. The design standard oxygen pressure of the oxygen lance nozzle is 1.07Mpa, and the design standard flow rate is 45000m3 / h.

[0037] Set the first threshold to 1.12 Mpa, and the second threshold to 1.03 Mpa.

[0038] The test is carried out at the stage of slag splashing for furnace protection. Nitrogen blowing with a flow rate of 45000m3 / h is stable for 60S, during which the actual pressure is P 0 ´=1.00Mpa, lower than the second threshold, the gas supply pipeline leaks, replace the spare oxygen gun, check the pipeline and replace the hose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com