A high-efficiency swing sinker for a computerized flat knitting machine

A computerized flat knitting machine and sinker technology, applied in textiles and papermaking, weft knitting, knitting and other directions, can solve problems such as insufficient pressing effect, falling off, and easy occurrence of springs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

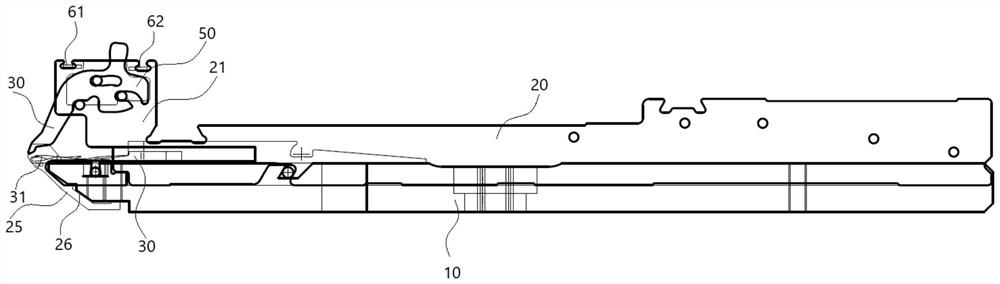

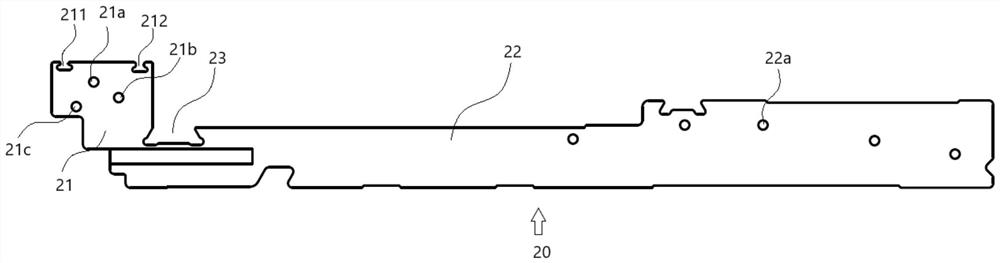

[0066] Example 1: seefigure 1 As shown, a needle plate insert installation structure of a computerized flat knitting machine includes inserts 20 that are fixed and installed on the needle plate 10 of a computerized flat knitting machine in parallel, and each adjacent insert 20 is formed for installing knitting needles. 30 needle slot, see further figure 2 As shown, the insert 20 adopts an integral molding, and the front end of the insert adopts the insert hinge mounting block 21. Preferably, in this embodiment, the insert 20 includes an insert body 22 integrally connected with the insert hinge mounting block 21. The insert body 22 is provided with a plurality of mounting holes 22a for fixed installation and connection with the needle plate 10, and a needle ruler ( figure 1 Not shown) the needle gauge limit groove 23; specifically preferably, in this embodiment, the outer diameter of the needle shank of the knitting needle 30 is in the range of 0.8-1.5mm;

[0067] In this emb...

Embodiment 2

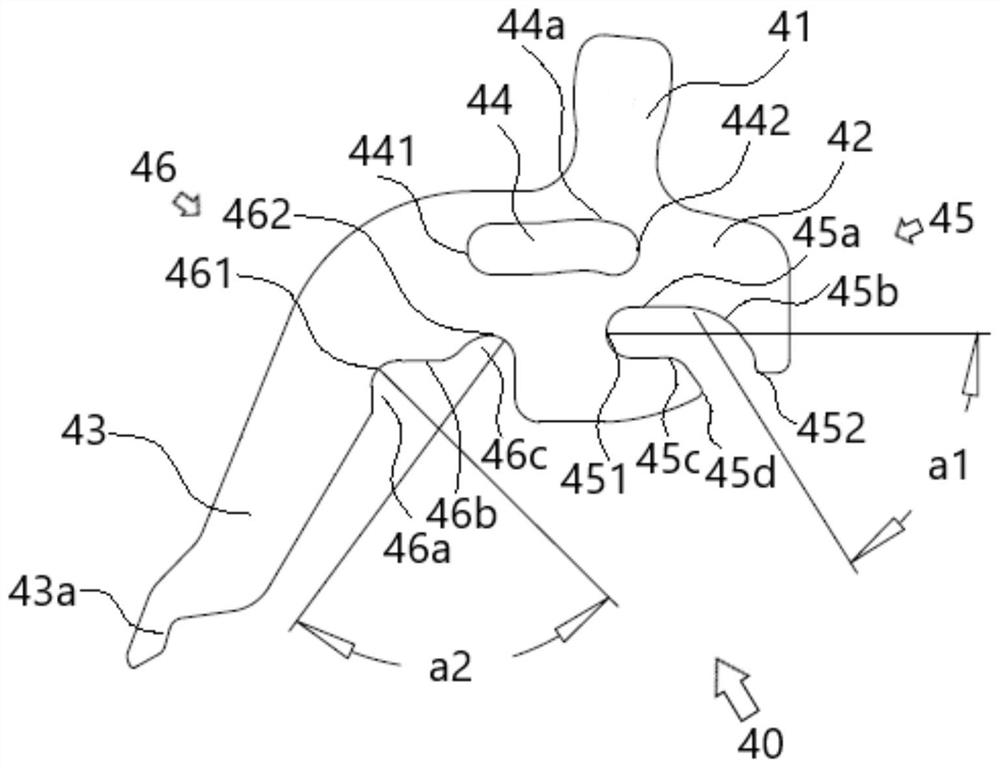

[0077] Example 2: see Figure 7 and Figure 8 As shown, a sinker installation structure with a large-stroke swing effect for a computerized flat knitting machine. The sinker 100 adopts an integrally formed structure, including a Sink triangle assembly located at the upper end and used for connecting with the computerized flat knitting machine head (not shown in the figure). ) drives the cooperating piece bell 110, the subsidence hinged mounting part 120 and the thread-pressing swing arm 130 matched with the knitting needle 200, and the sinking hinged mounting part 120 connects the piece-picking bell 110 and the thread-pressing swing arm 130 as one; specifically preferably , in this embodiment, the outer diameter range of the needle bar of the knitting needle 210 is 5-9mm; Cooperate with the needle tongue 211 of the knitting needle 210 to be used for the tooth mouth piece 230 for stripping, and the thread pressing tongue 211 performs a large-stroke swing relative to the tooth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com