Combustor used for gas stove

A technology of burners and gas stoves, which is applied in the direction of gas fuel burners, burners, and the transportation of non-flammable liquids/gases, etc., and can solve problems such as inconvenient maintenance and cleaning, unsightly appearance of burners, and easy yellow flames, etc. To achieve the effect of easy maintenance and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

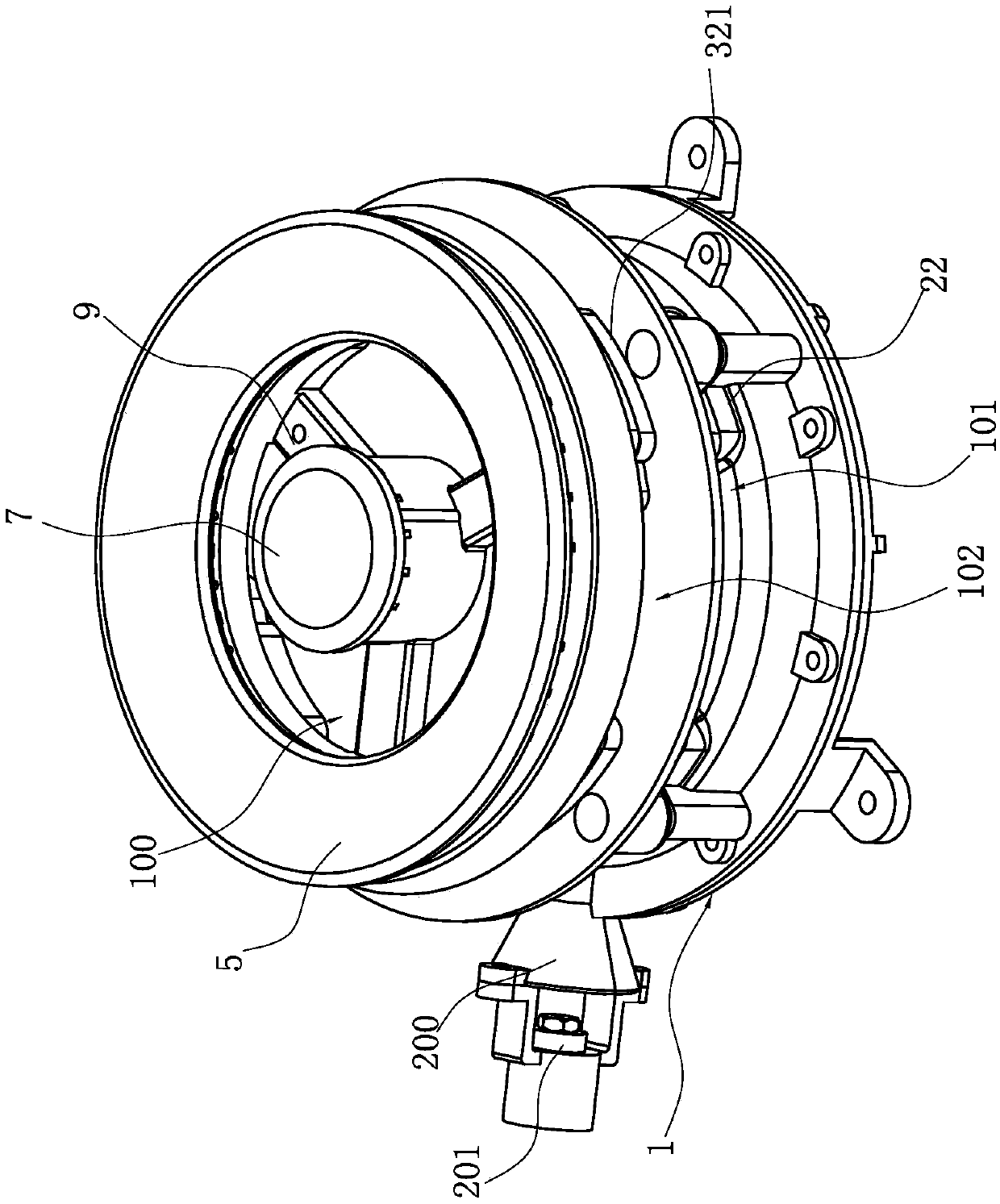

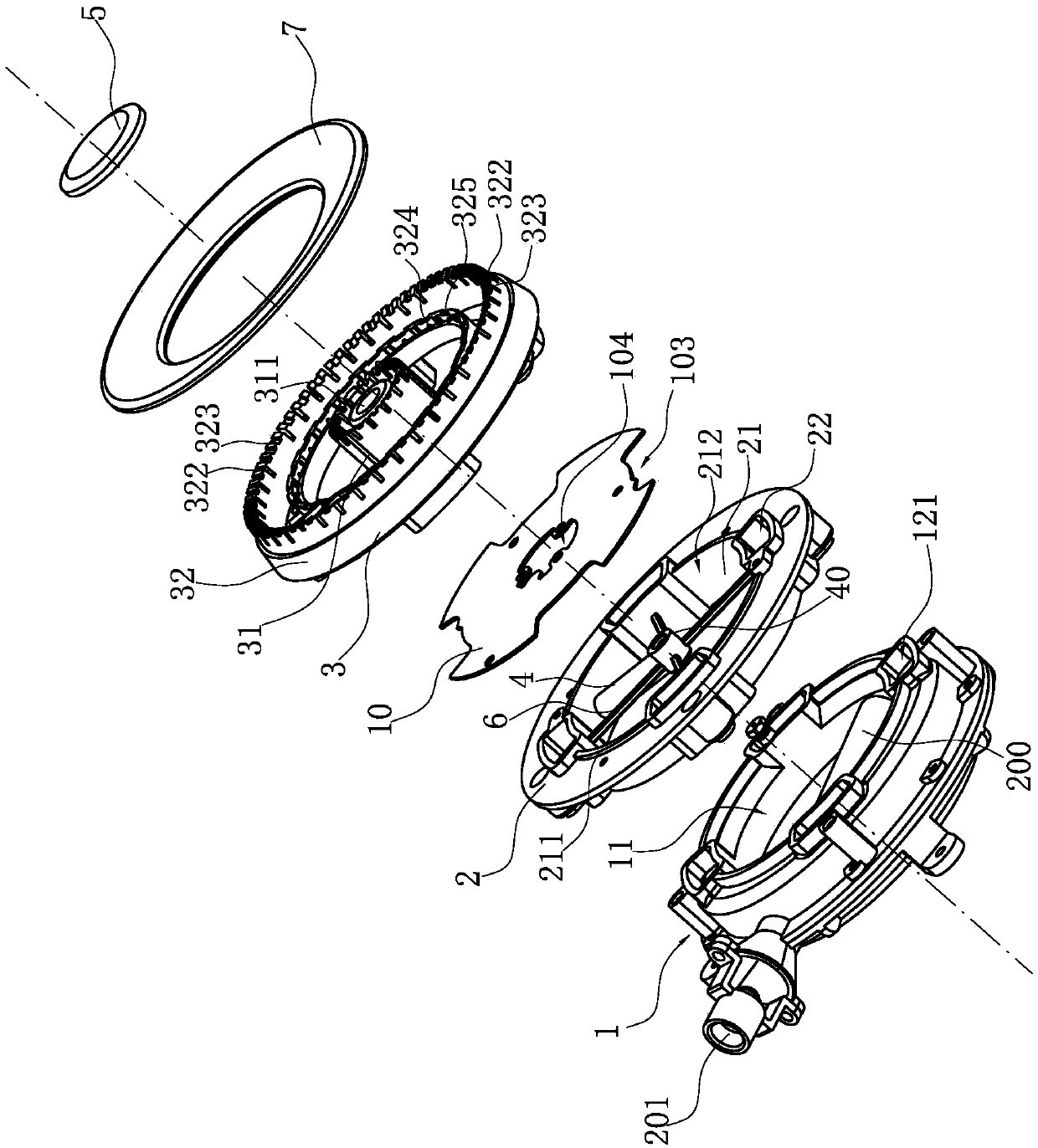

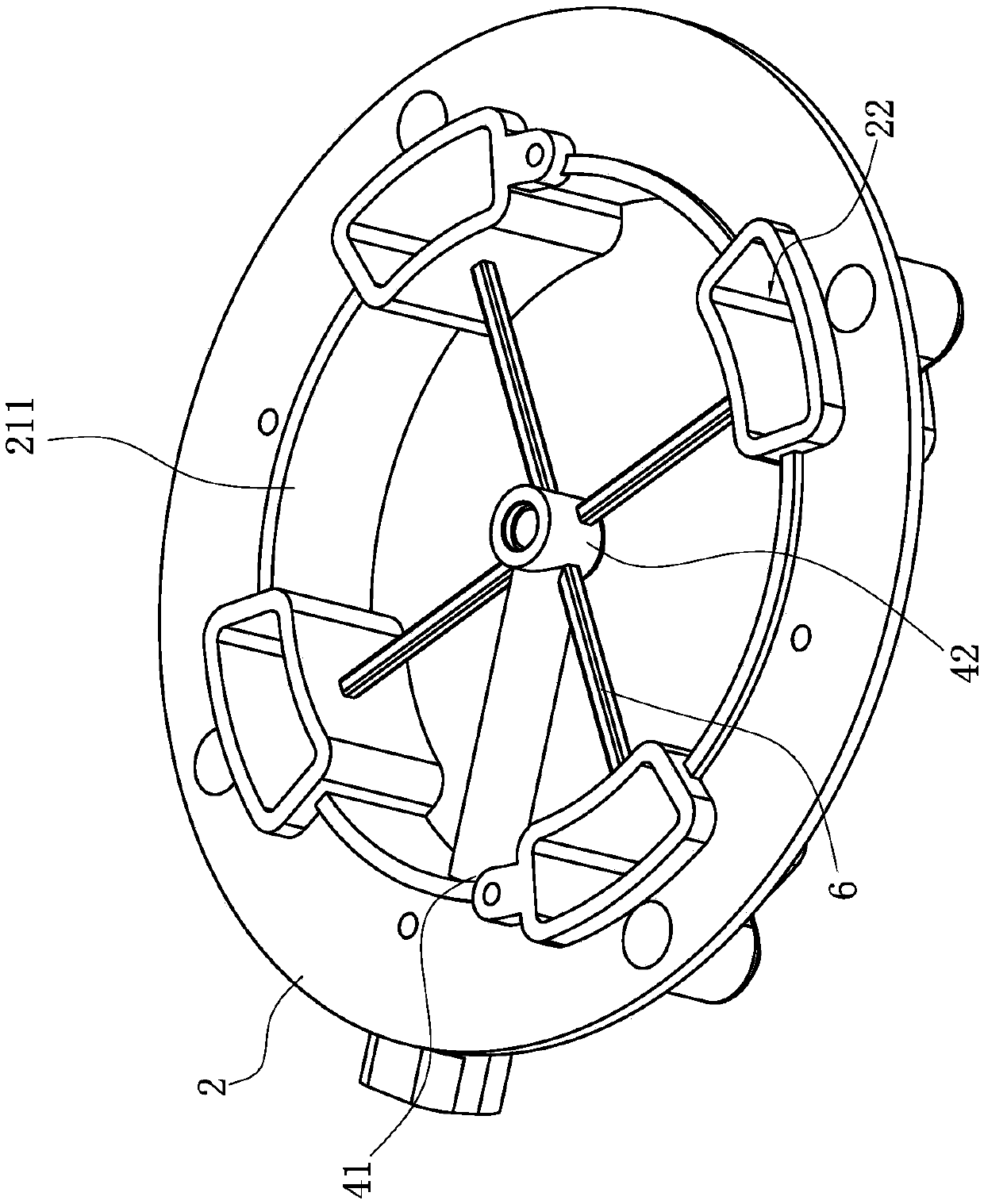

[0042] Such as Figure 1-7 As shown, it is the best embodiment of the present invention. The burner used in the gas stove can be applied to the traditional upward air-intake burner and can also be applied to the Italian Sabaf burner such as Europe. The burner includes a The base 1 with the concave cavity 11 facing upward, the first connecting body 2 arranged on the base 1, the first connecting body 2 includes a plate body with a central hole 21, and the hole wall of the central hole 21 protrudes upwards A circle of annular wall 211 is formed, the annular cavity 212 surrounded by the annular wall 211 corresponds to the concave cavity 11, and the second connecting body 3 arranged on the first connecting body 2, the second connecting body 3 includes an inner ring body 31, The central position of the inner ring body 31 has a vertical first inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com