Loading test device for shark pincers

A technology for loading a test device and shark tongs, which is applied in the field of ship engineering and can solve the problems of increased expenses and high prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

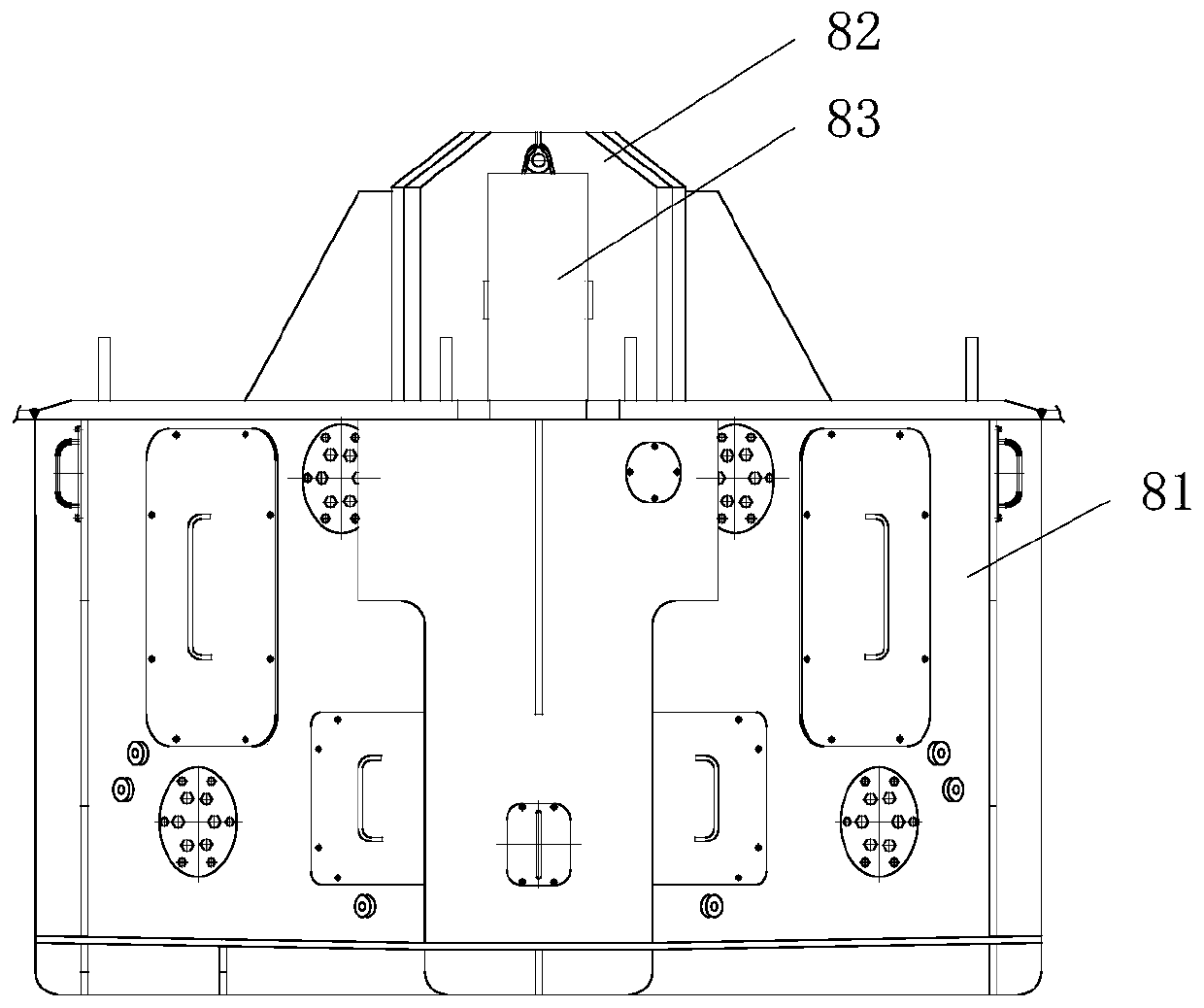

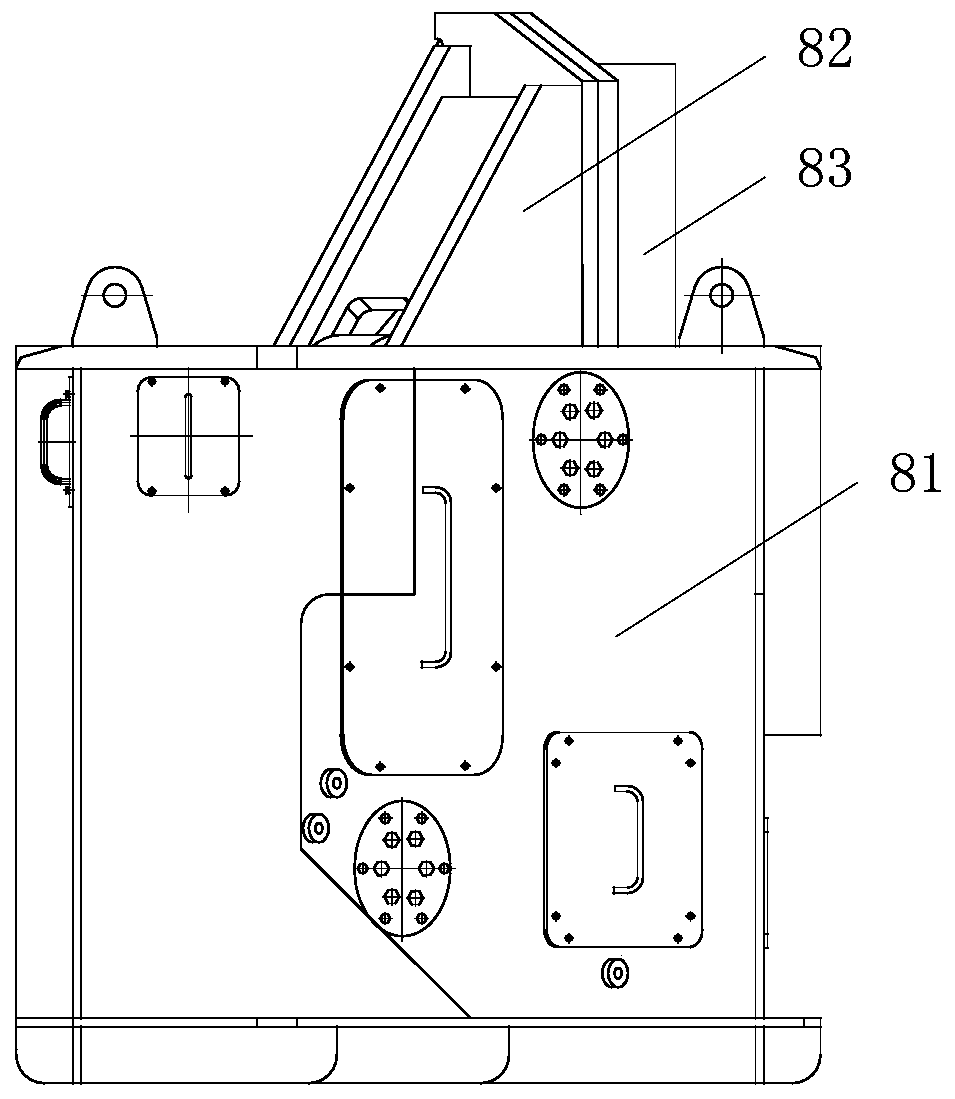

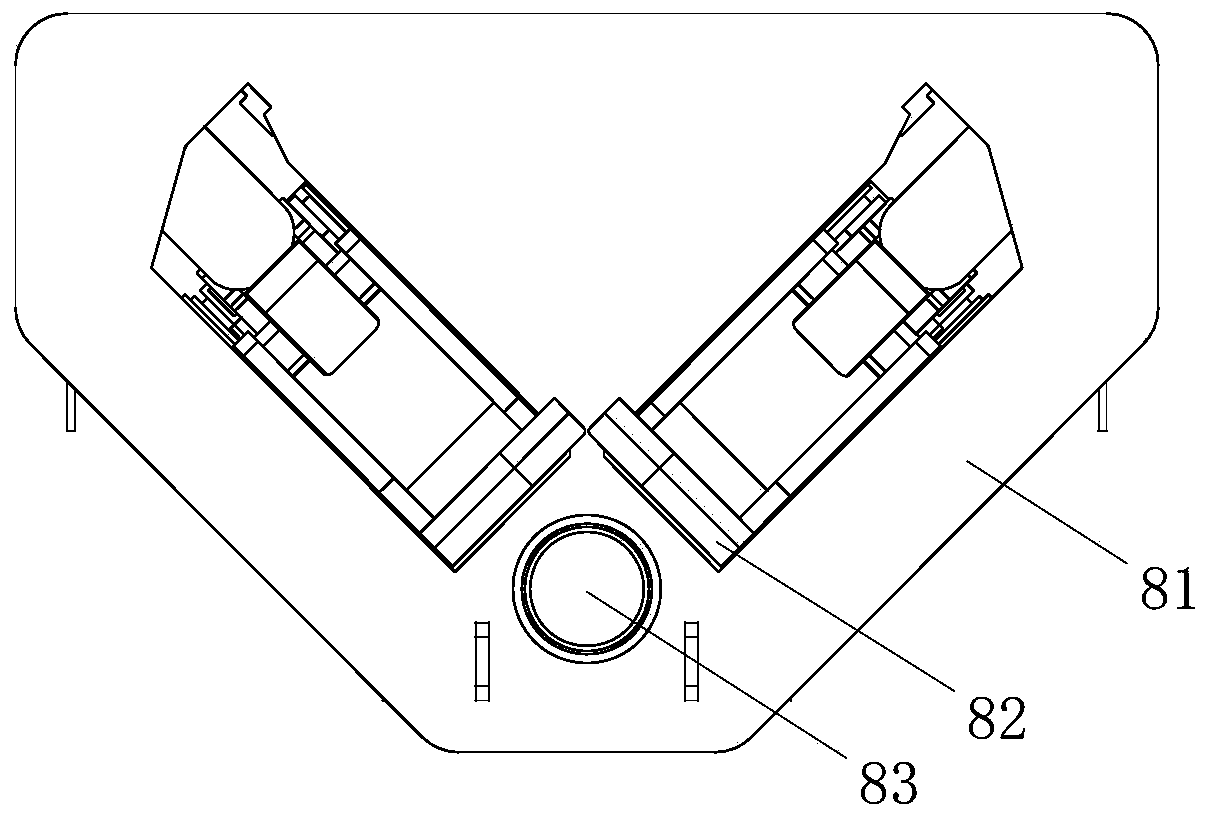

[0044] In an embodiment of the present disclosure, the shark jaw includes a link type shark jaw. Figure 1-Figure 3 It is a three-view diagram of the link type shark jaw provided by the embodiment of the present disclosure. see Figure 1-Figure 3 , The shark jaw includes a casing 81, a nipper assembly and a top pin 83. The nipper assembly includes two nippers 82 that can be flipped and stretched independently. During work, the anchor chain or steel cable is fixed between the two nippers 82; when not in use, the two nippers 82 fall back to the box 81 Inside and flush with the top of the casing 81. The jacking pin 83 is located between the two nippers 82 , and can lift the drooping anchor chain or steel cable between the two nippers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com