A method of equipment load test

A technology of equipment load and load test, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of high cost and troublesome operation, and achieve the effect of simple operation method, high safety and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

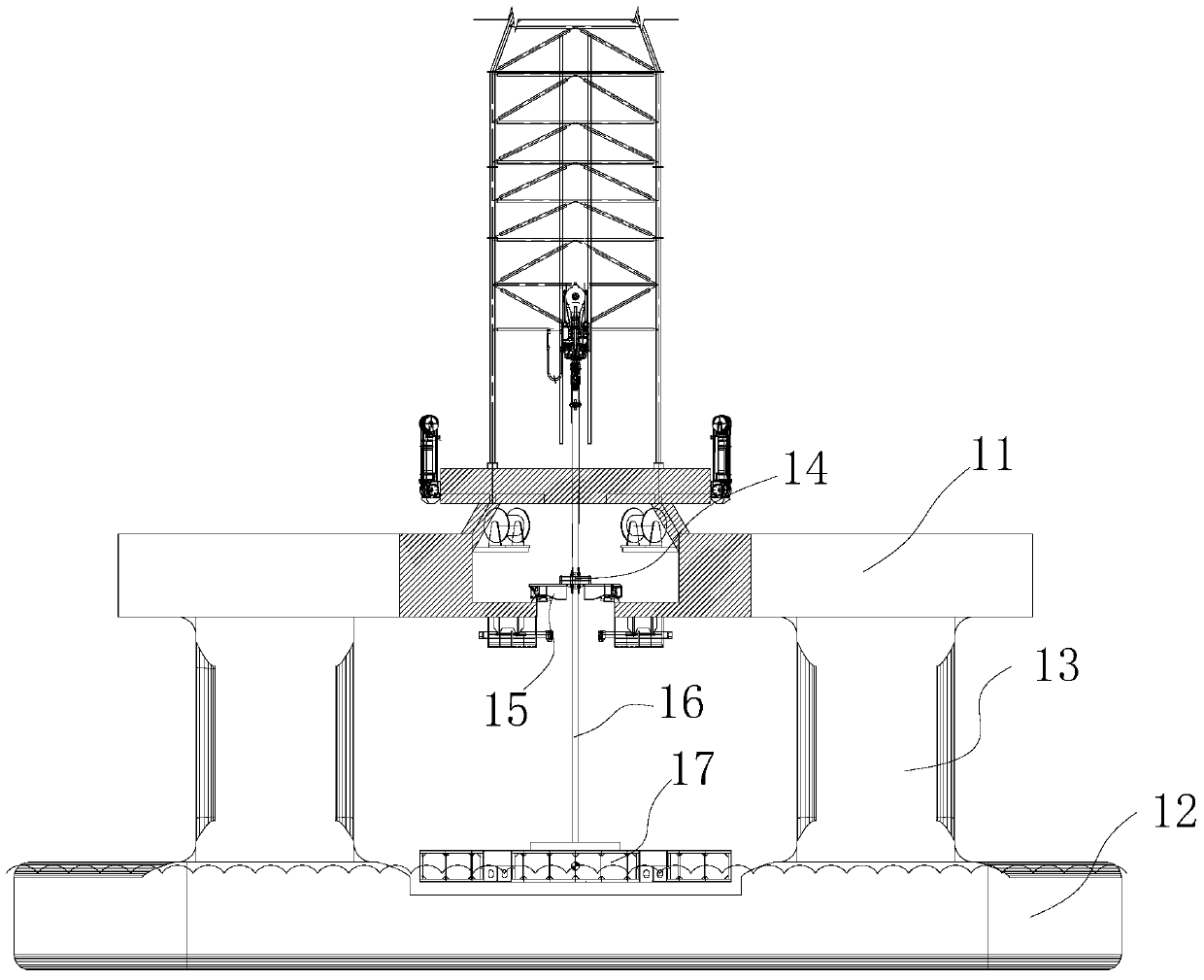

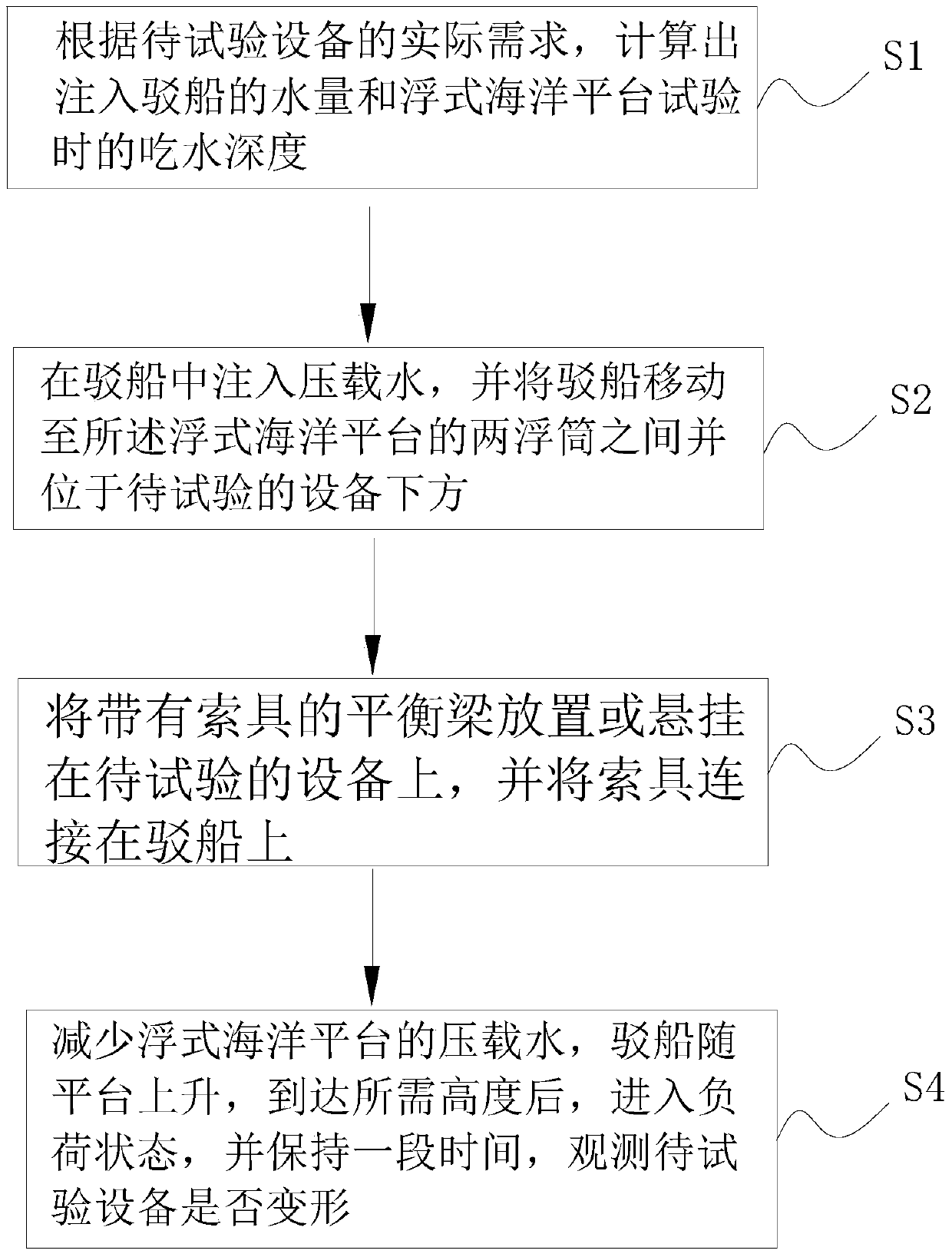

[0022] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

[0023] In the field of ocean engineering, the equipment configured on the floating offshore platform (for example, semi-submersible floating drilling platform), such as trolleys, casing tensioners, top drives, etc., must be subjected to load tests to evaluate the In the case of preset load, whether the performance is stable. The present invention proposes a method of equipment load test aimed at the floating offshore platform. The present invention cleverly utilizes the ballast water system of the floating offshore platform itself, and uses the buoyancy of the floating offshore platform to reverse the load to achieve the load. The effect of the test.

[0024] see figure 1 , which is a structural schematic diagram of the test equipment of the floating offshore p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com