Train power supply load test device

A technology of power supply load and test device, applied in the field of train power supply load test device, can solve the problem of lack of compatible load test equipment and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

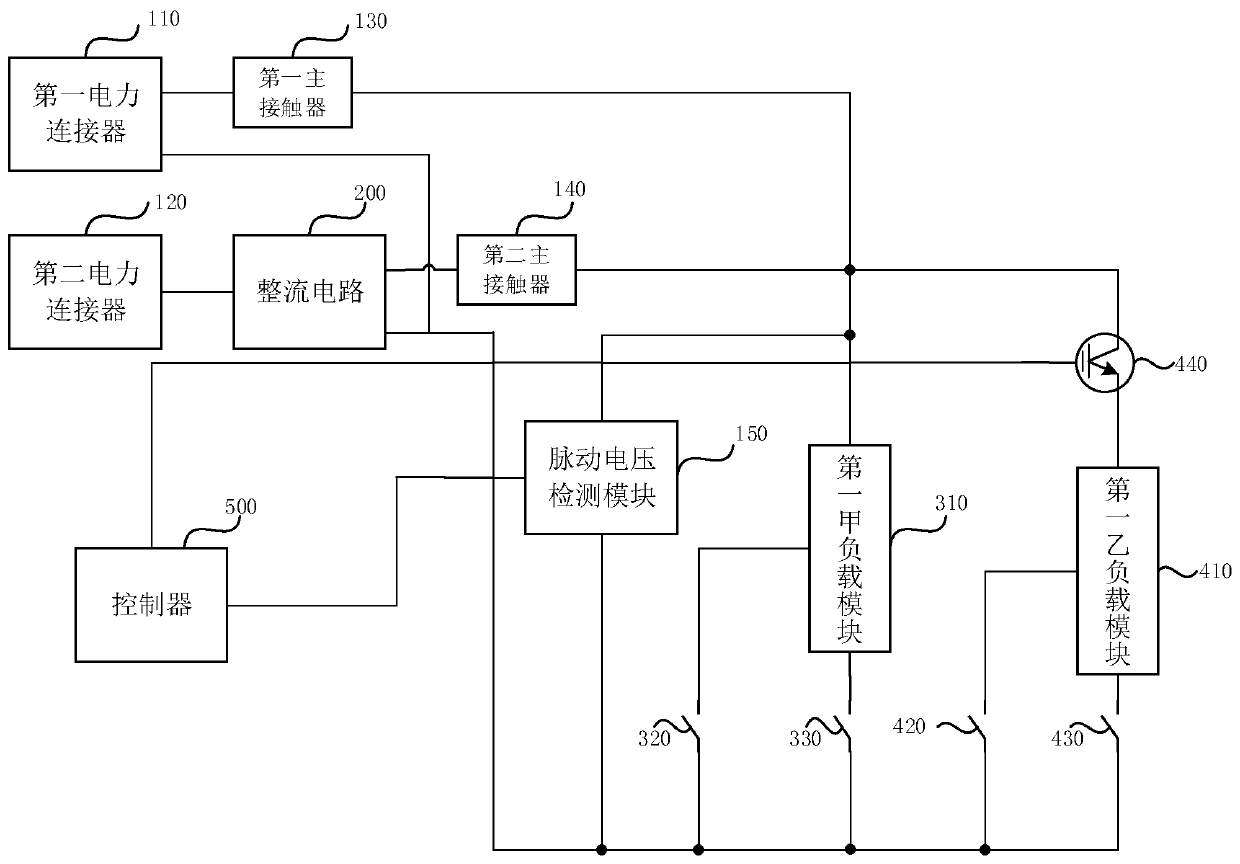

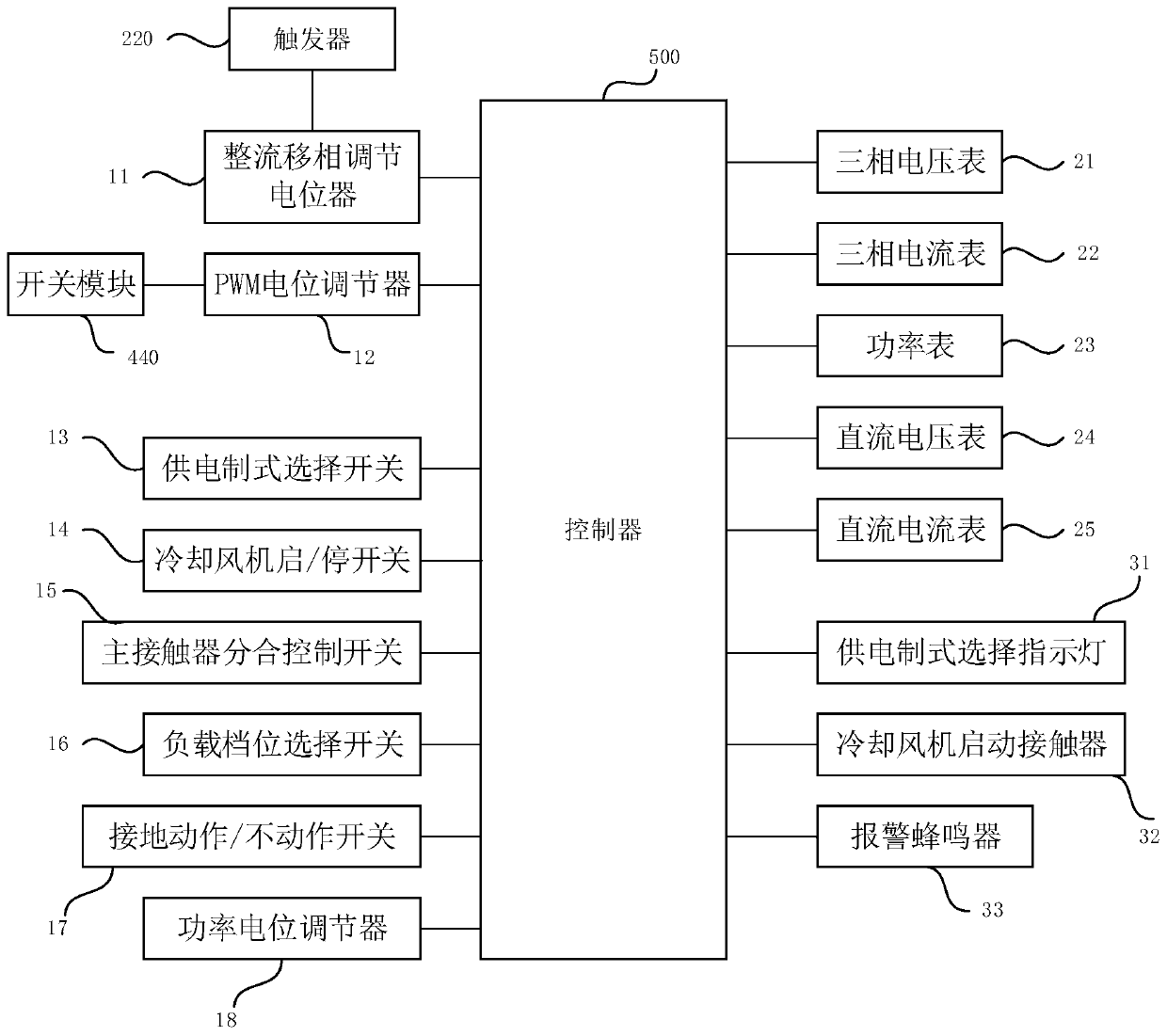

[0017] figure 1 It is a structural block diagram of a train power supply load test device provided in Embodiment 1 of the present invention. Exemplary, refer to figure 1 , the train power supply load test device includes: a first power connector 110, a second power connector 120, a first main contactor 130, a second main contactor 140, a rectifier circuit 200, a switch module 440, at least two first load module (exemplary reference figure 1 , shows two first load modules, wherein the first first A load module 310, the second first B load module 410), the first A switch 320 corresponding to the first A load module 310 and the second A switch 330, the first B switch 420 and the second B switch 430 corresponding to the first B load module 410, the pulsating voltage detection module 150 and the controller 500;

[0018] Wherein, the first power connector 110 is used to connect a DC power supply, the first output end of the first power connector 110 is connected to the first load...

Embodiment 2

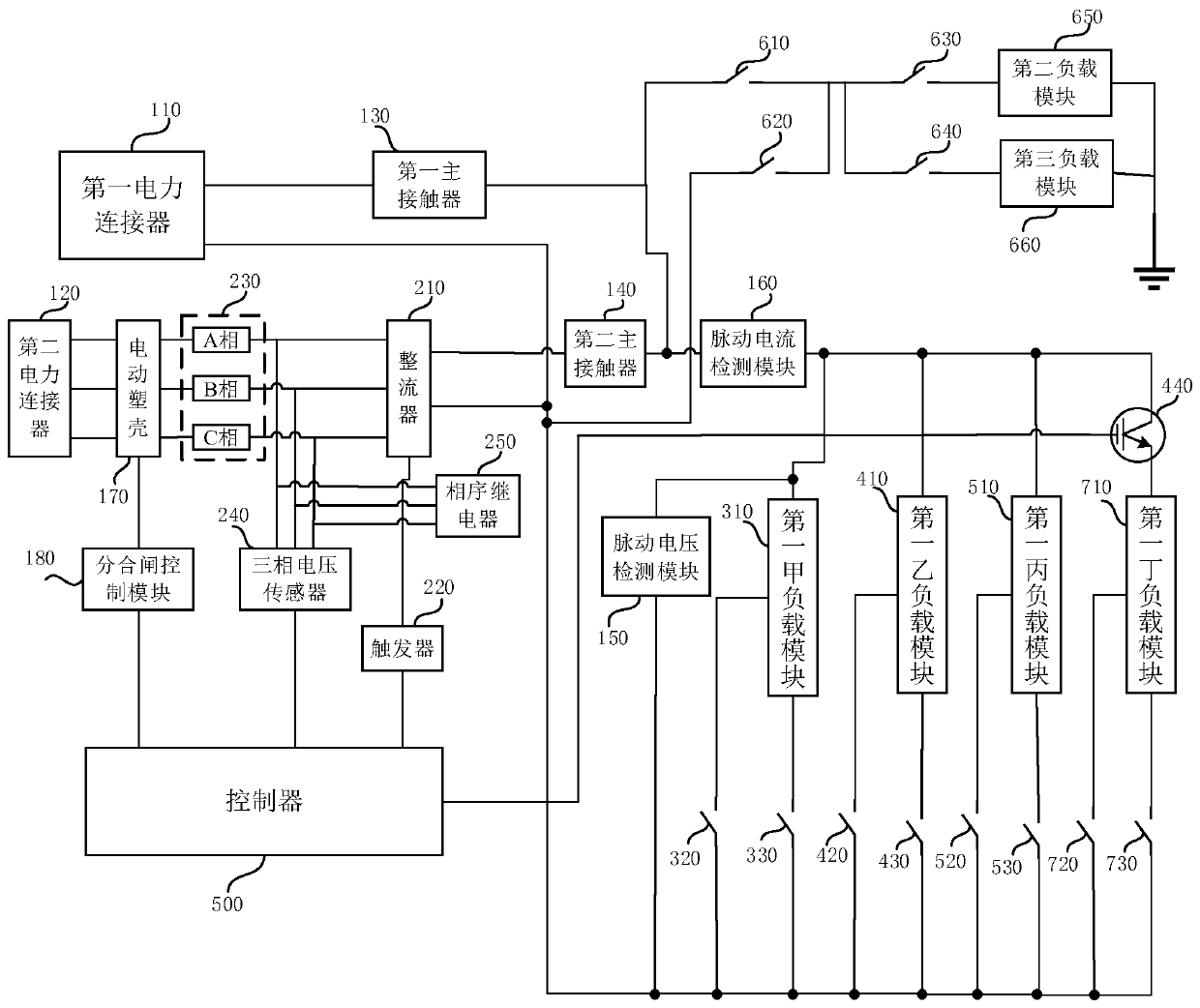

[0024] figure 2It is a structural block diagram of a train power supply load test device provided in Embodiment 2 of the present invention. On the basis of the above technical solutions, for example, refer to figure 2 , the train power supply load test device also includes a second load module 650, a third load module 660, a third switch 610, a fourth switch 620, a fifth switch 630 and a sixth switch 640, the first end of the third switch 610 is connected to the The first load connection line is connected, the first end of the fourth switch 620 is connected to the second load connection line, the second end of the third switch 610 is electrically connected to the second end of the fourth switch 620, the first end of the fifth switch 630 end is electrically connected to the second end of the third switch 610, the second end of the fifth switch 630 is electrically connected to the first end of the second load module 650, the second end of the second load module 650 is grounde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com