Solar photovoltaic ultra-light component

A technology of solar photovoltaics and photovoltaic modules, applied in photovoltaic modules, photovoltaic power generation, electrical components, etc., can solve the problems of heavy weight of photovoltaic modules, inability to apply roof photovoltaic projects, photovoltaic modules cannot meet the installation method of long frame, and achieve weight reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific drawings.

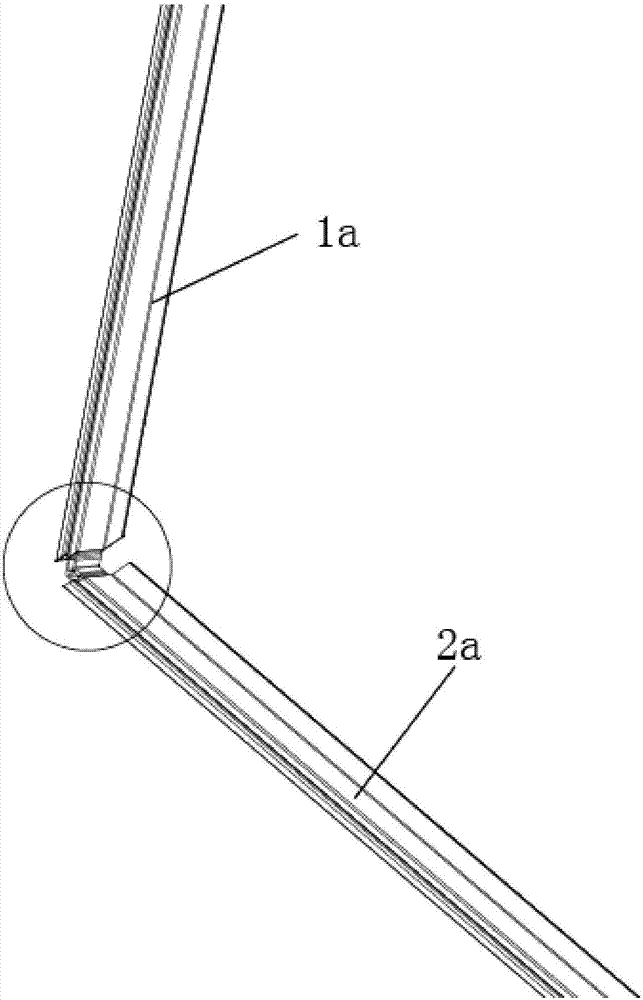

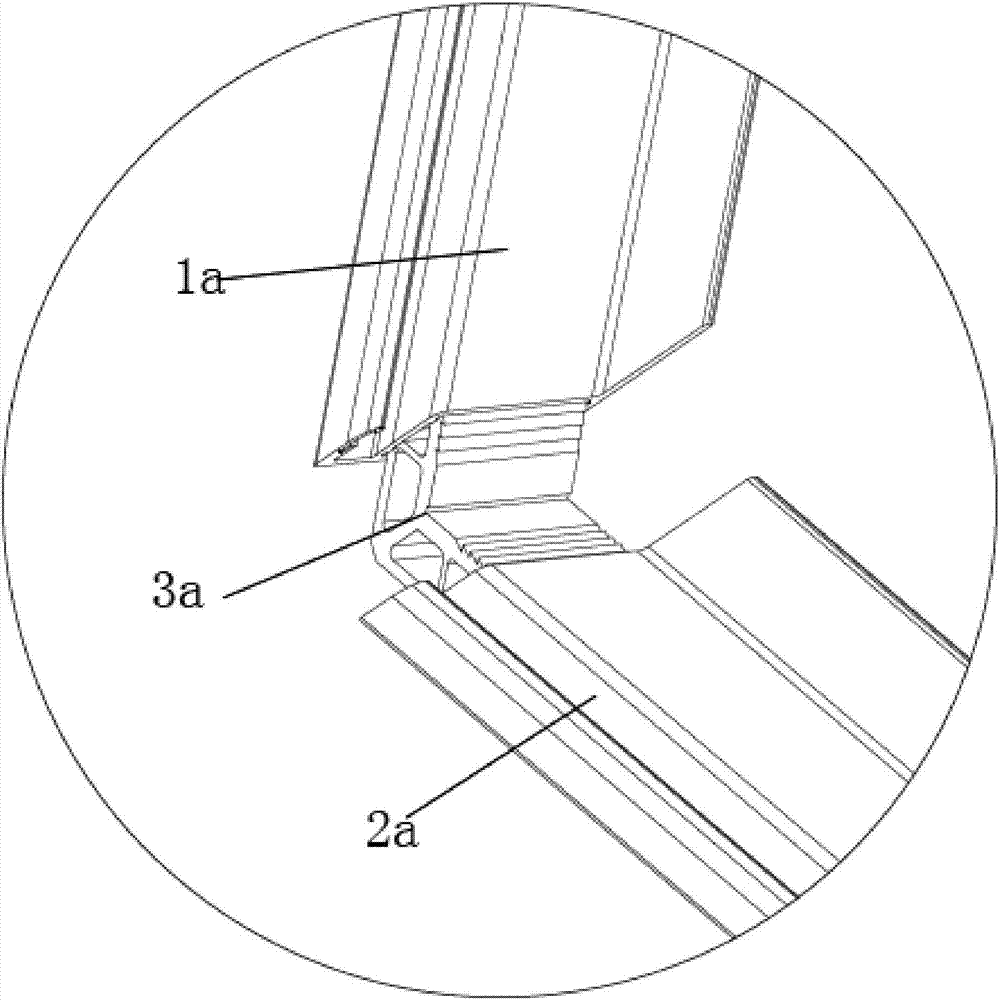

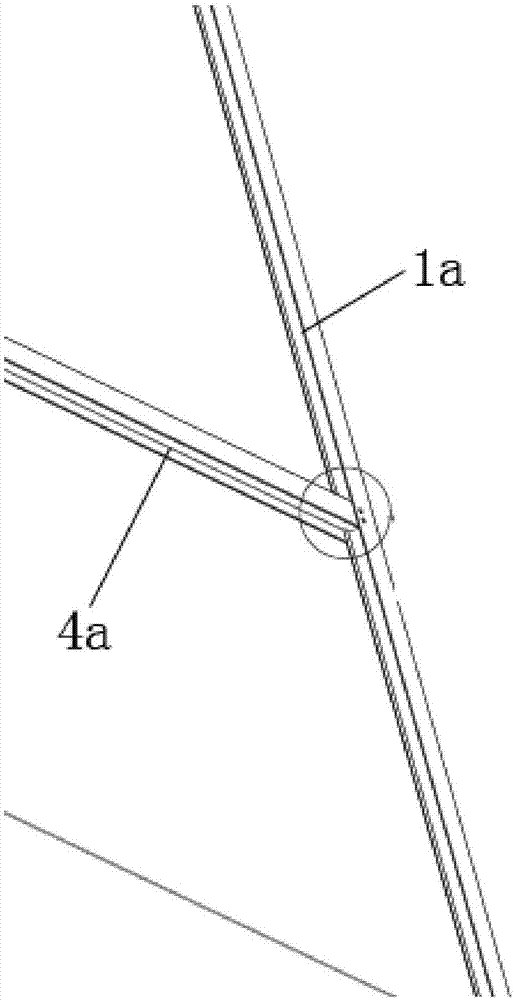

[0030] like Figure 5 , Image 6 As shown, the solar photovoltaic ultra-light module of the present invention adopts a U-shaped 6×9 photovoltaic module and uses 0.85mm glass; wherein, the frame of the solar photovoltaic ultra-light module consists of a long frame 1 and a short frame 2 with screws Fasten, the back of the frame is provided with reinforcing ribs 3 as a support, and two reinforcing ribs 3 are installed along the direction of the long frame 1.

[0031] like Figure 9 , Figure 10 As shown, the long frame side 1 includes side A, side B and side C, side A and side C are vertically arranged at the upper and lower ends of side B respectively, side A is located inside side B, side C is located outside side B , the first photovoltaic module installation groove 4 is set under the side A; the short frame 2 has an inner cavity structure 5, and the second photovoltaic mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com