Aero-engine bleed air test equipment and test method

A technology of aero-engine and test equipment, which is applied in the direction of engine testing, jet engine testing, gas turbine engine testing, etc. It can solve the problems of no air source interface and inability to accurately measure the process parameters of bleed air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

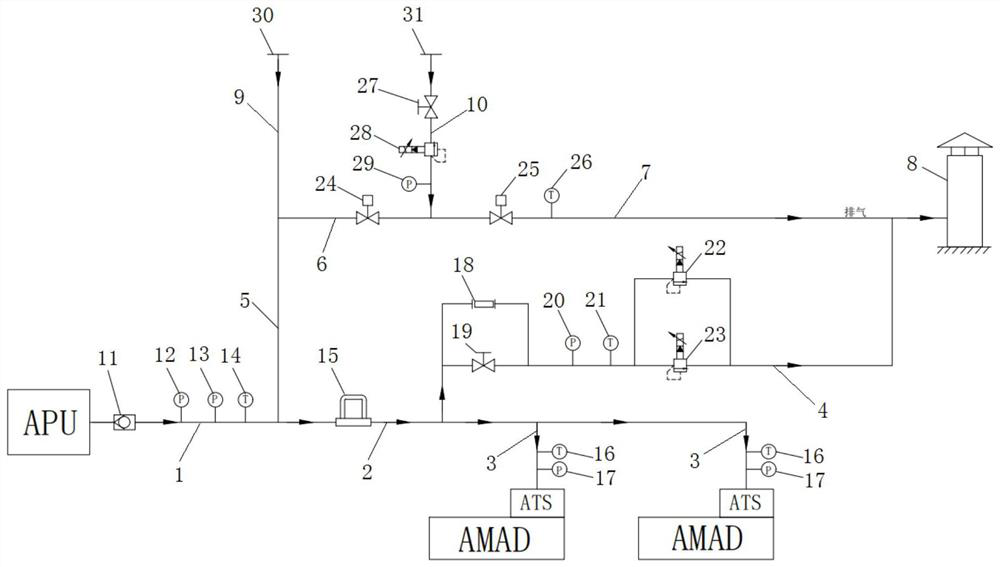

[0052] In order to make the purpose, advantages and characteristics of the present invention clearer, the aeroengine bleed air test equipment and test method proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0053] The aeroengine bleed air test equipment provided by this embodiment is as follows: figure 1 As shown, it includes APU bleed air output pipeline 1, flow monitoring pipeline 2, ATS bleed air input pipeline 3, environmental control bleed air pipeline 4, two-way delivery pipeline 5, two-way switching pipeline 6, exhaust pipeline 7 , exhaust tower 8, first gas source output pipeline 9, second gas source output pipeline 10.

[0054] The inlet of APU bleed air output pipeline 1 is connected to the outlet of APU bleed air, and its outlet is respectively connected to the inlet of flow monitoring pipeline 2 and one end of two-way delivery pipeline 5 . The APU bleed air output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com