Slicing device for bamboo production and processing

A slicing device and slicing technology, which is applied in the direction of manufacturing tools, feeding devices, wood processing equipment, etc., can solve the problems of slicing deviation, affecting production, and inability to cut bamboo into long strips of the same size, so as to facilitate discharging , the effect of meeting the needs of the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

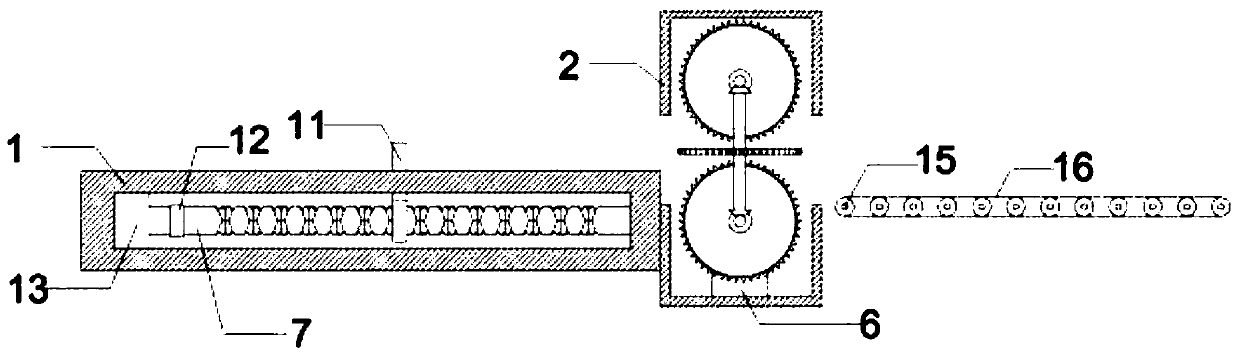

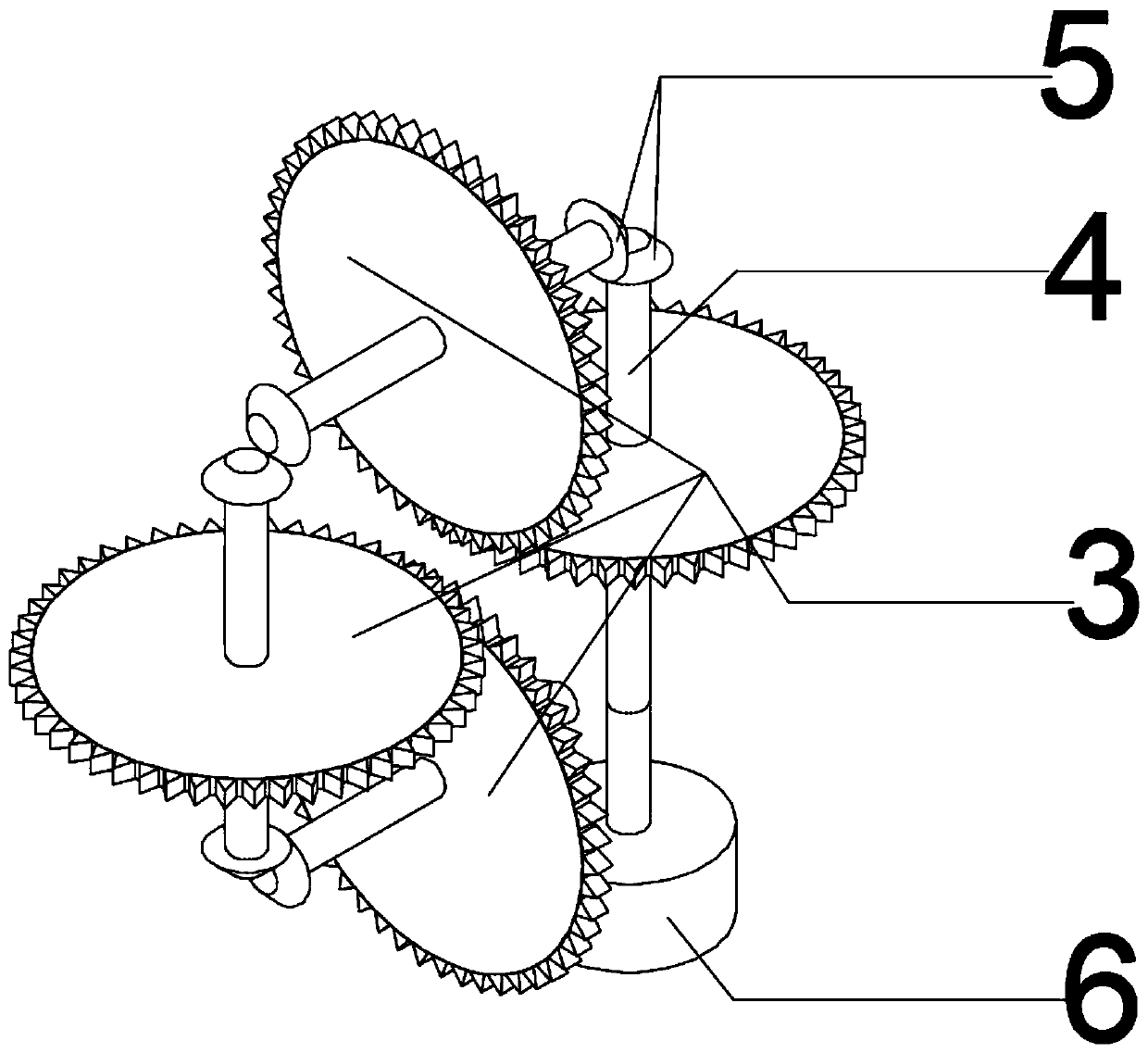

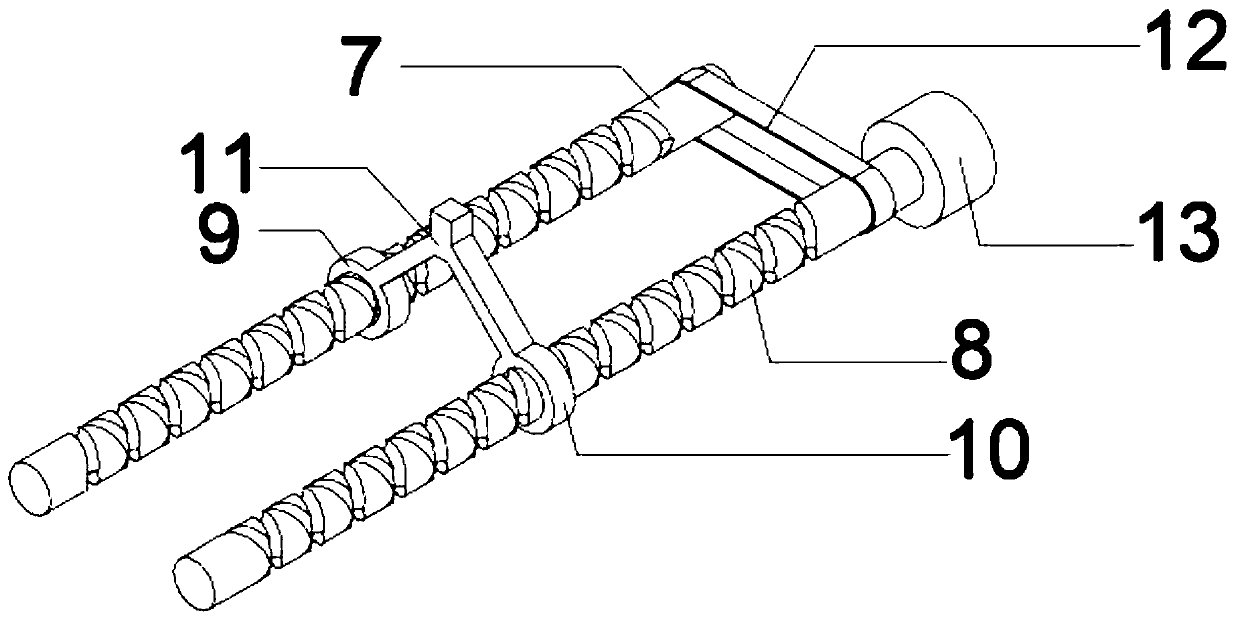

[0020] see Figure 1-4 , the present embodiment provides a kind of slicing device for bamboo production and processing, comprising feeding housing 1, slicing housing 2, feeding mechanism for sending bamboo to slicing mechanism, slicing mechanism for equally slicing bamboo and for A discharging mechanism for discharging the equally cut bamboo; the feeding mechanism is arranged in the feeding casing 1, and a slicing casing 2 is provided on one side of the feeding casing 1; a slicing mechanism is provided inside the slicing casing 2 , and the slicing mechanism is provided with a discharge mechanism away from the side of the feeding shell 1; the slicing mechanism includes a slicing saw blade 3, a slicing rotating shaft 4, a bevel gear 5 and a slicing motor 6; the slicing motor 6 is fixed on the slicing shell 2 inside, and its rotating end is connected with one end of one of the plurality of slice rotating shafts 4 in the slice housing 2; the plurality of slice rotating shafts 4 ar...

Embodiment 2

[0028] This embodiment is further improved on the basis of Embodiment 1. The improvement is: in order to facilitate the operation of the control device, a control device for controlling the operation of the slicing motor 6 and the feeding motor 13 is provided on one side of the feeding housing 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com