Rhodococcus jj-3 and its application in degrading acrylic acid

A technology of Rhodococcus rhodochrous and JJ-3 is applied in the field of biological treatment of environmental pollutants, which can solve the problems of difficult control, high operation cost, secondary pollution of heavy metal catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

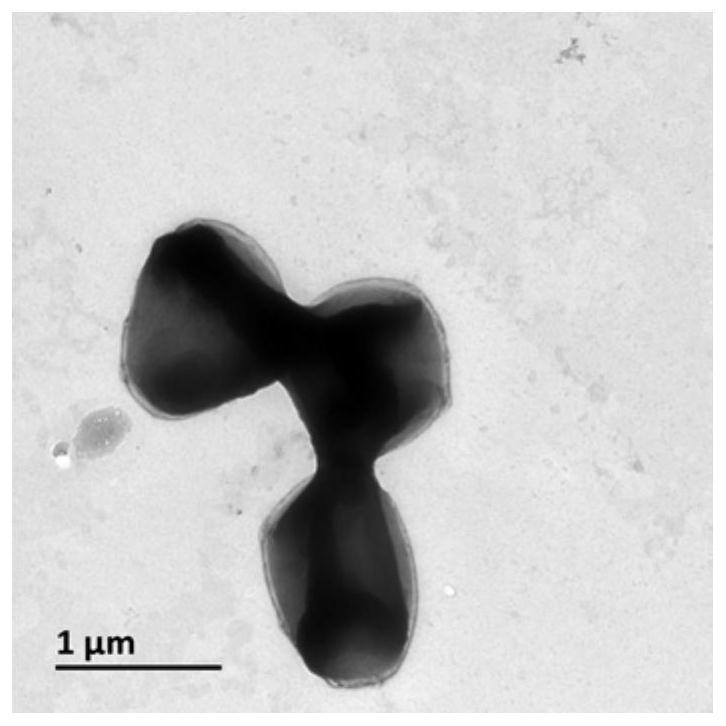

[0027] Example 1: Isolation, purification and identification of RhodococcusruberJJ-3

[0028] 1. Isolation and purification of Rhodococcusruber JJ-3

[0029] RhodococcusruberJJ-3 is screened from the sludge of the wastewater treatment pond of Zhejiang Satellite Energy Co., Ltd. The specific steps are as follows:

[0030] Acrylic acid liquid selection medium, the preparation method is as follows: NH 4 Cl 540mg·L -1 , K 2 HPO 4 1000mg·L-1 , KH 2 PO 4 1000mg·L -1 , NaCl 500mg·L -1 , yeast extract powder 200mg·L -1 , acrylic acid 1000mg·L -1 , MgSO 4 ·7H 2 O 16mg·L -1 , CaCl 2 4mg·L -1 , CuSO 4 4mg·L -1 , FeSO 4 4mg·L -1 , MnSO 4 4mg·L -1 , the solvent is water, the pH value is 7.0, and it is sterilized at 121° C. for 20 minutes.

[0031] Acrylic solid selection medium: NH 4 Cl 540mg·L -1 , K 2 HPO 4 1000mg·L -1 , KH 2 PO 4 1000mg·L -1 , NaCl 500mg·L -1 , yeast extract powder 200mg·L -1 , peptone 400mg·L -1 , acrylic acid 1000mg·L -1 , MgSO ...

Embodiment 2

[0045] Embodiment 2 Rhodococcus erythrococcus JJ-3 fermented culture fluid

[0046] (1) Incline cultivation

[0047] Inoculate Rhodococcus Erythrococcus JJ-3 into the slant medium and culture at 30°C for 3 days to obtain the bacterial slant; the final concentration of the slant medium consists of: NH 4 Cl 540mg·L -1 , K 2 HPO 4 1000mg·L -1 , KH 2 PO 4 1000mg·L -1 , NaCl 500mg·L -1 , yeast extract powder 200mg·L -1 , peptone 400mg·L -1 , acrylic acid 1000mg·L -1 , MgSO 4 ·7H 2 O 16mg·L -1 , CaCl 2 4mg·L -1 , CuSO 4 4mg·L -1 , FeSO 4 4mg·L -1 , MnSO 4 4mg·L -1 , the solvent is water, the pH value is 7.0, and 18g·L -1 agar.

[0048] (2) Seed culture: Pick colonies from the slant of the bacteria and inoculate them into LB medium, cultivate at 30°C for 12 hours to obtain seed liquid; the final concentration of the LB medium is composed of: NaCl 10g L -1 , yeast extract powder 5g·L -1 , peptone 10g·L -1 , the solvent is water, the pH value is 7.0;

[00...

Embodiment 3

[0050] Example 3: RhodococcusruberJJ-3 acrylic acid degradation performance detection

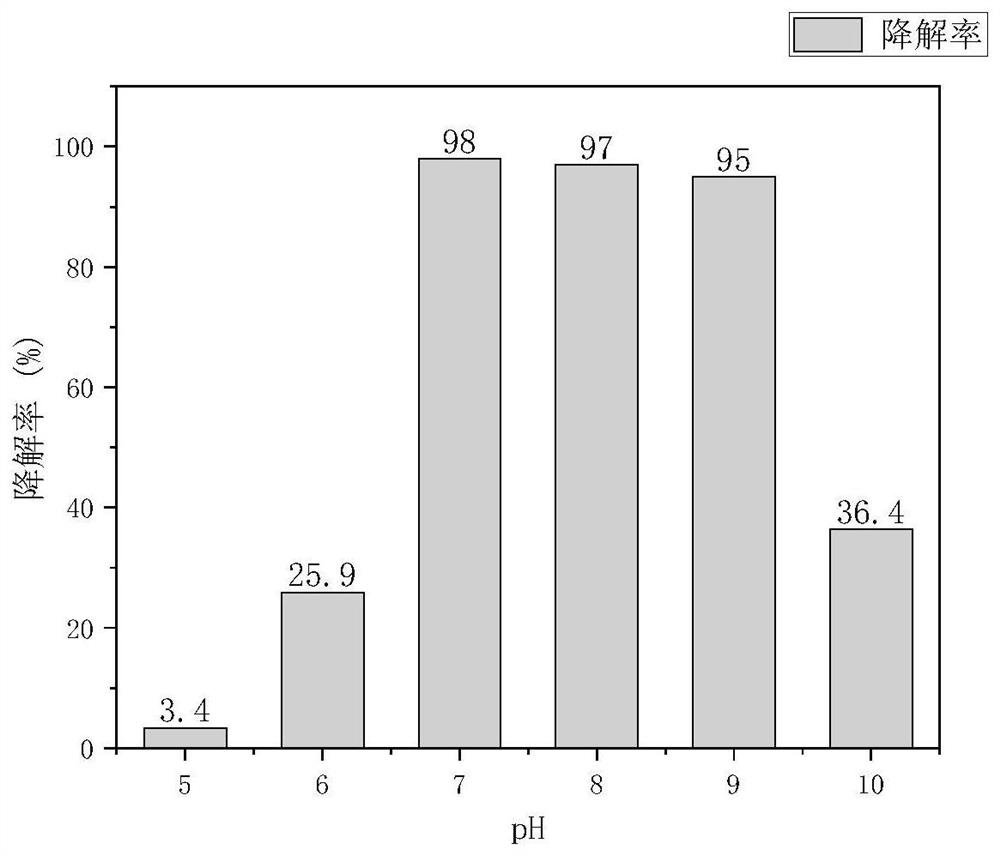

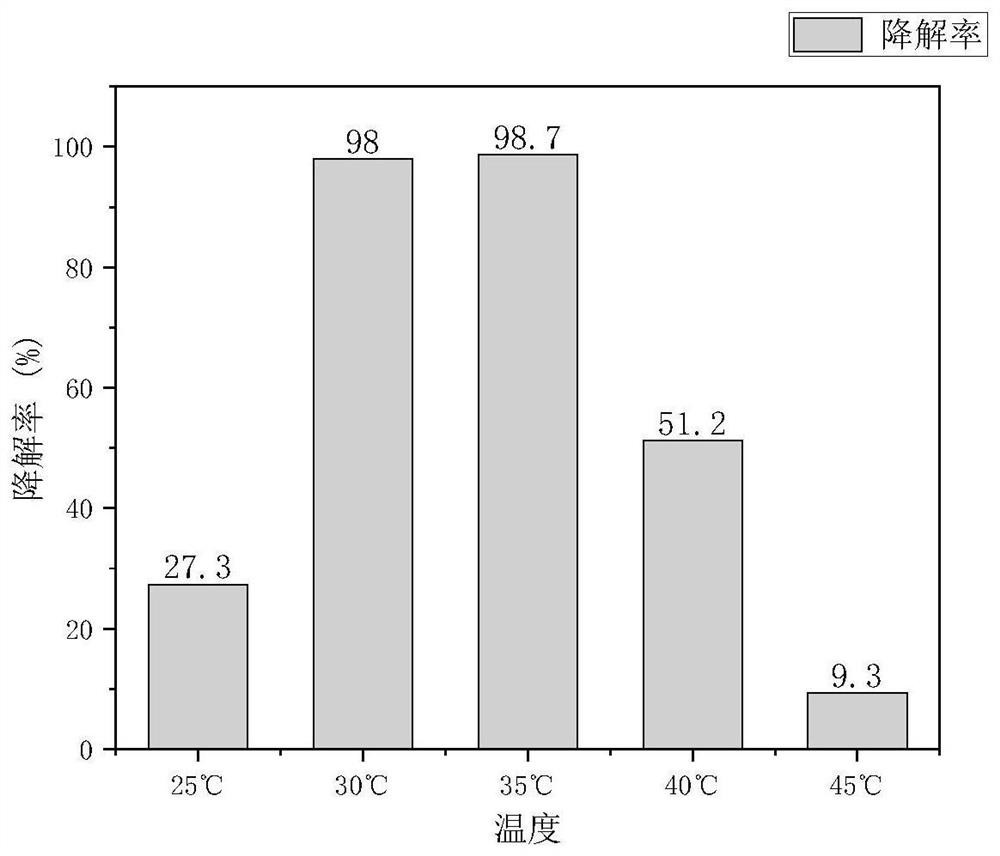

[0051] 1. Investigate the performance of Rhodococcus Erythrococcus JJ-3 in degrading acrylic acid under different initial pH conditions

[0052] The experiment of degrading acrylic acid by Rhodococcus rubrum JJ-3 at different initial pHs found that pH = 7.0 is the optimum pH, and the degradation rate is the highest at this time. The specific implementation steps are as follows:

[0053] With acrylic acid as carbon source (adding concentration 1000mg L -1 ), according to volume concentration 5% inoculum size will OD 600 The 0.8 containing bacteria suspension (prepared by the method of embodiment 2) is inoculated in the acrylic acid liquid selection medium (composition is the same as embodiment 2) of different pH values (pH values are respectively 5.0, 6.0, 7.0, 8.0, 9.0, 10.0), 35°C, 160rpm shaking culture for 16 hours to obtain the culture solution, and use high performance liquid chr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com