Bending machine compensation workbench

A bending machine and workbench technology, applied in the field of bending machine compensation workbench, can solve the problems of installation hole and inclined block compensation accuracy, insufficient machining accuracy, etc., achieve convenient operation, improve compensation accuracy, and avoid displacement error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

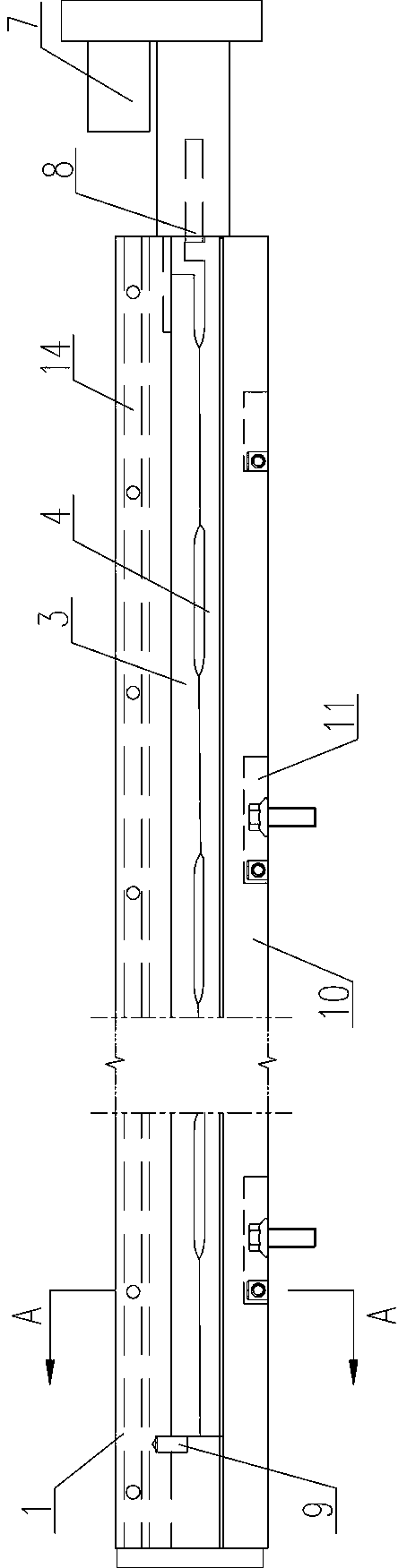

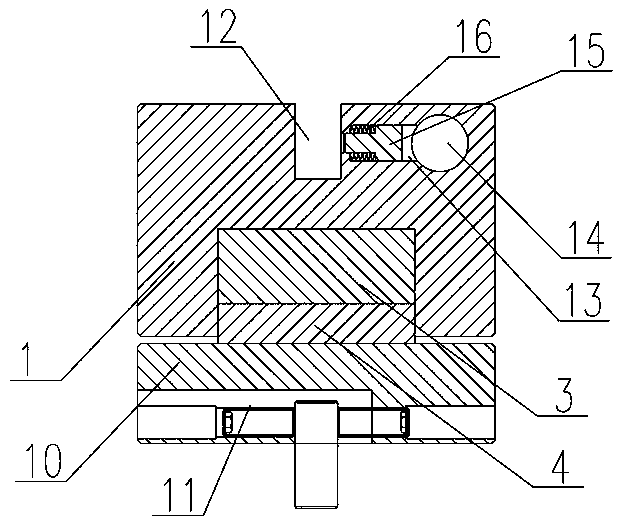

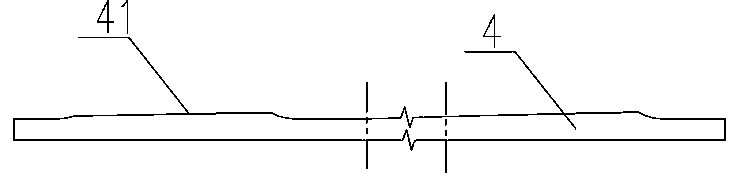

[0013] see Figure 1-4 , the present embodiment includes an elongated base 10, the bottom surface of the base 10 is provided with a mounting hole 11 for fixing to the bending machine frame, the top of the base 10 is equipped with a mold mounting seat 1, and the bottom surface of the mold mounting seat 1 is provided with a concave groove along the entire length. Groove 5, a drive plate 4 is installed on the top surface of the base in the groove 5, an electric push rod 7 is installed at one end of the base 10, the piston rod 8 of the electric push rod 7 is fixedly connected with the drive plate 4, and the upper edge of the drive plate 4 The length direction is provided with several inclined planes 41, wherein the inclined plane 41 in the middle has the largest inclination angle, and the inclined planes 41 inclination angles located at both ends gradually decrease. An upper inclined block 3 is paired on the top of each inclined plane 41, and an upper inclined block 3 is provided a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com