Integral inclined block mechanical compensation workbench

A workbench and integral technology, applied in the field of integral inclined block mechanical compensation workbench, can solve the problems of insufficient machining accuracy, the influence of installation holes and inclined block compensation accuracy, etc., to achieve convenient operation, avoid displacement errors, and improve compensation accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

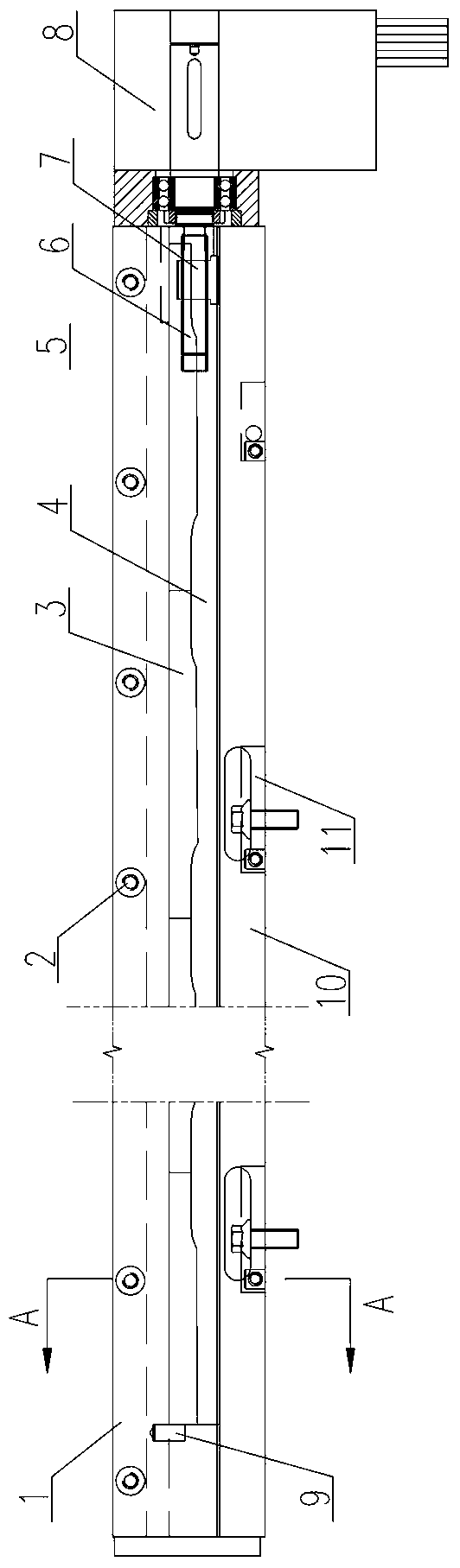

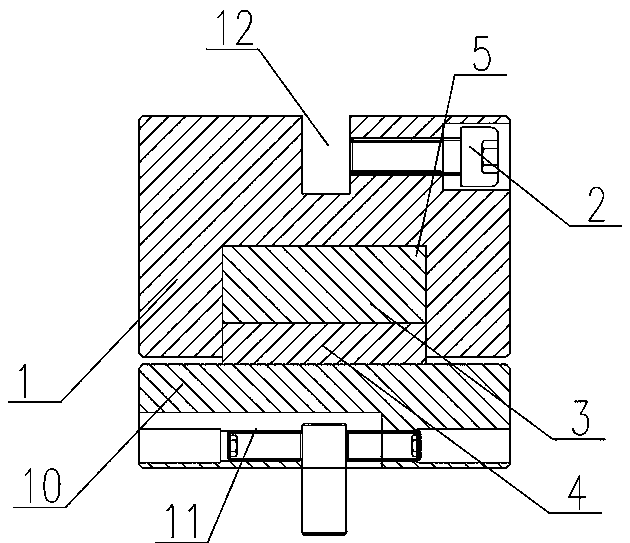

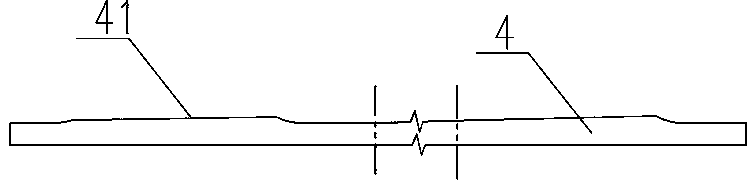

[0016] See Figure 1-4 This embodiment includes a long base 10, the bottom of the base 10 is provided with a mounting hole 11 for fixing with the frame of the bending machine, the top of the base 10 is equipped with a mold mounting seat 1, and the bottom of the mold mounting seat 1 is provided with a recess along the full length Slot 5, a drive plate 4 is installed in the groove 5 on the top surface of the base. One end of the drive plate 4 is fixed with a nut 7, and the outer end of the base 10 is equipped with a motor 8, and the output shaft of the motor 8 is equipped with a nut 7 7 Threaded screw 6, the drive plate 4 is provided with a number of inclined surfaces 41 along the length direction. Among them, the inclined surface 41 in the middle has the largest inclination angle, and the inclined surface 41 at both ends gradually decreases. The top of each inclined surface 41 is matched An upper inclined block 3, the bottom of the upper inclined block 3 is provided with an incl...

Embodiment 2

[0019] See Figure 5 The mechanism of this embodiment is basically the same as that of the first embodiment. The difference is that the mold mounting seat 1 is located on the side of the mold mounting groove 12 and is equipped with a hydraulic clamping mechanism for clamping the mold. The hydraulic clamping mechanism includes a mold mounting seat 1 A row of several piston holes 13 arranged in the longitudinal direction, one end of the piston hole 13 faces the mold mounting groove 12, each piston hole 13 is equipped with a piston rod 15 matching the piston hole 13, and the mold mounting seat 1 is provided with a line along the length The hydraulic oil hole 14 is arranged, the hydraulic oil hole 14 is communicated with all the piston holes 13, and one end of the hydraulic oil hole 14 is communicated with the outside for installing the hydraulic oil pipe connected with the oil pump.

[0020] The piston hole 13 in this embodiment has an inward step, and a spring 16 for resetting the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com