Damping mute wheel and movable equipment

A mobile device and quiet technology, applied in the direction of casters, wheels, wheels made of non-metallic materials, etc., can solve the problems of large vibration and noise, limited deformation of flexible tread, etc., and achieve the effect of reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

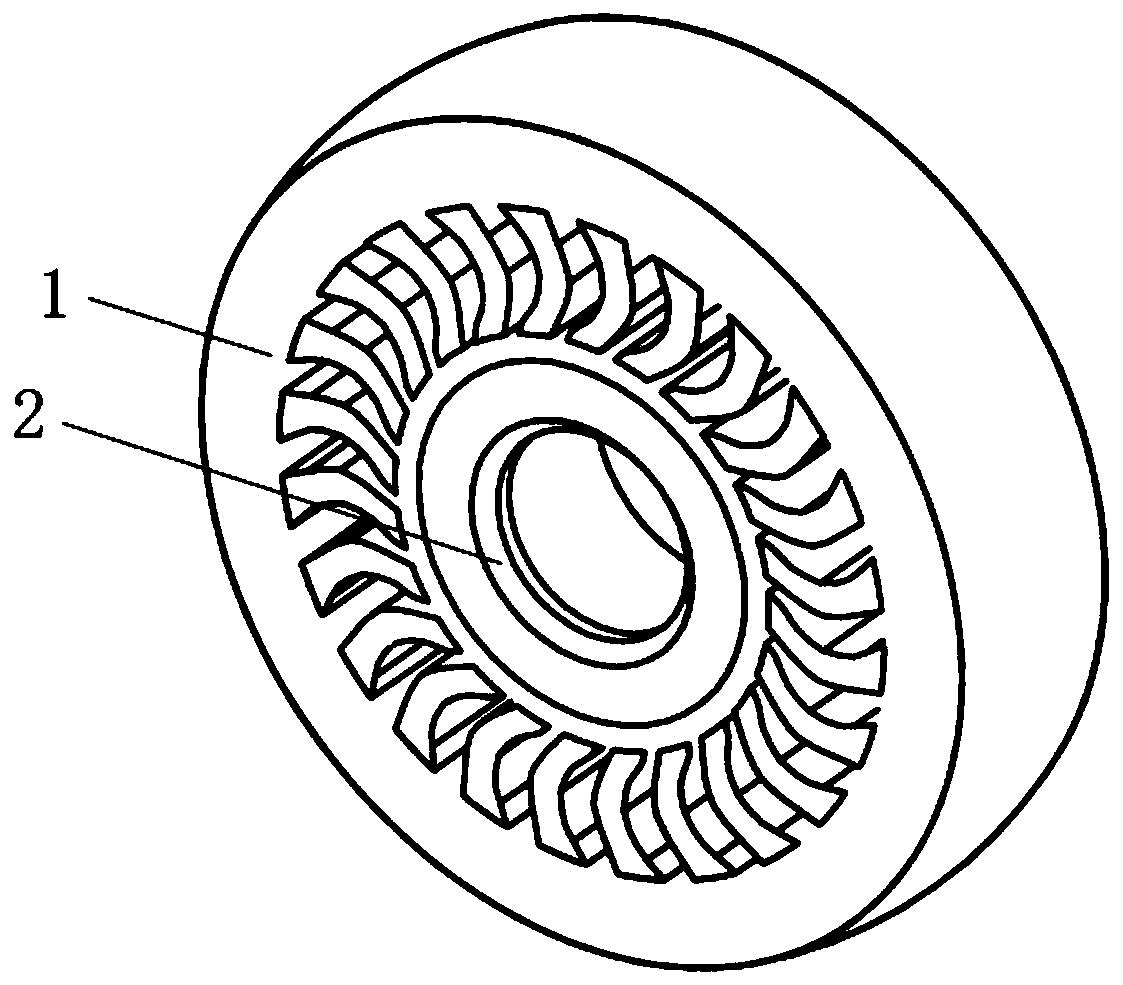

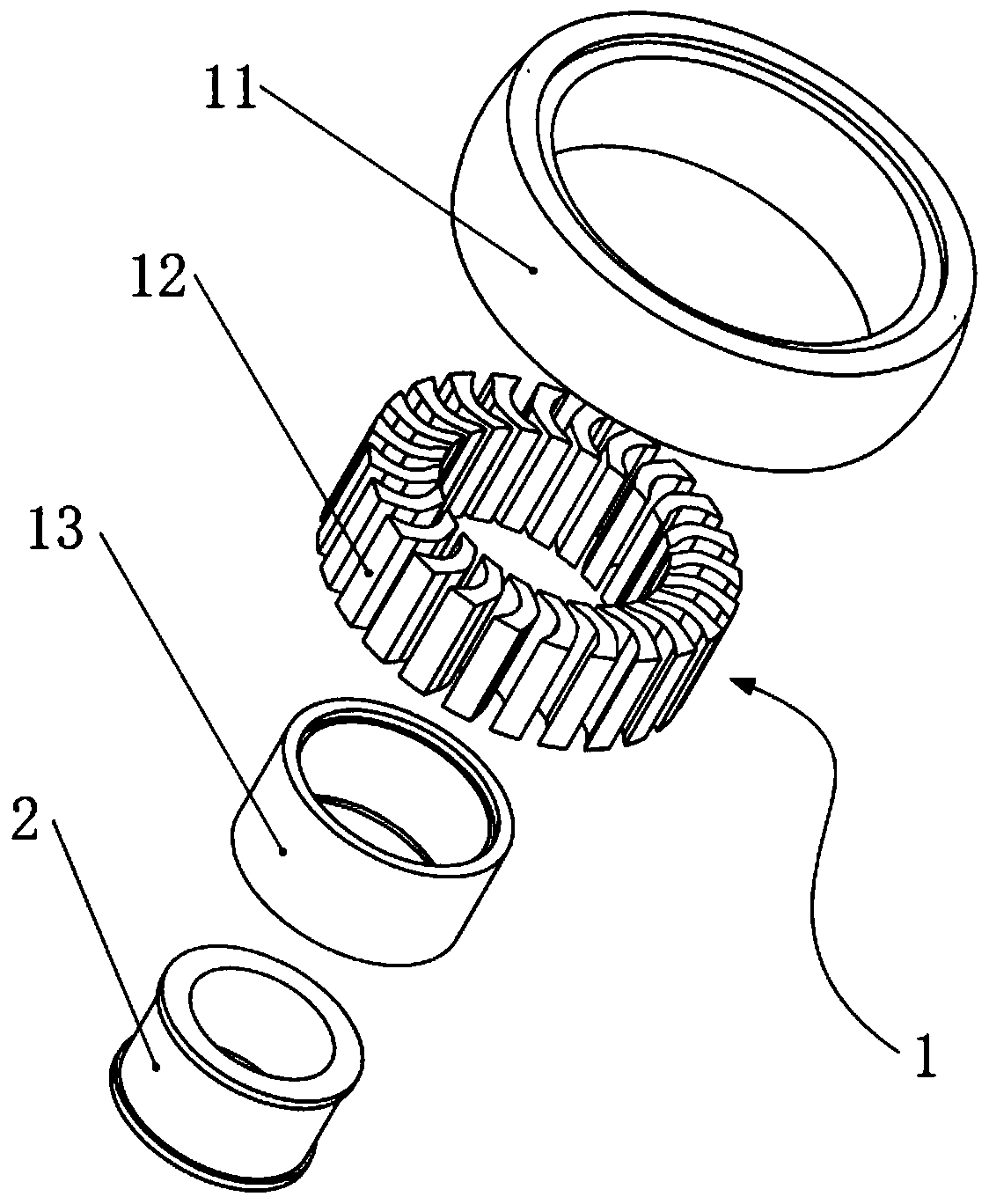

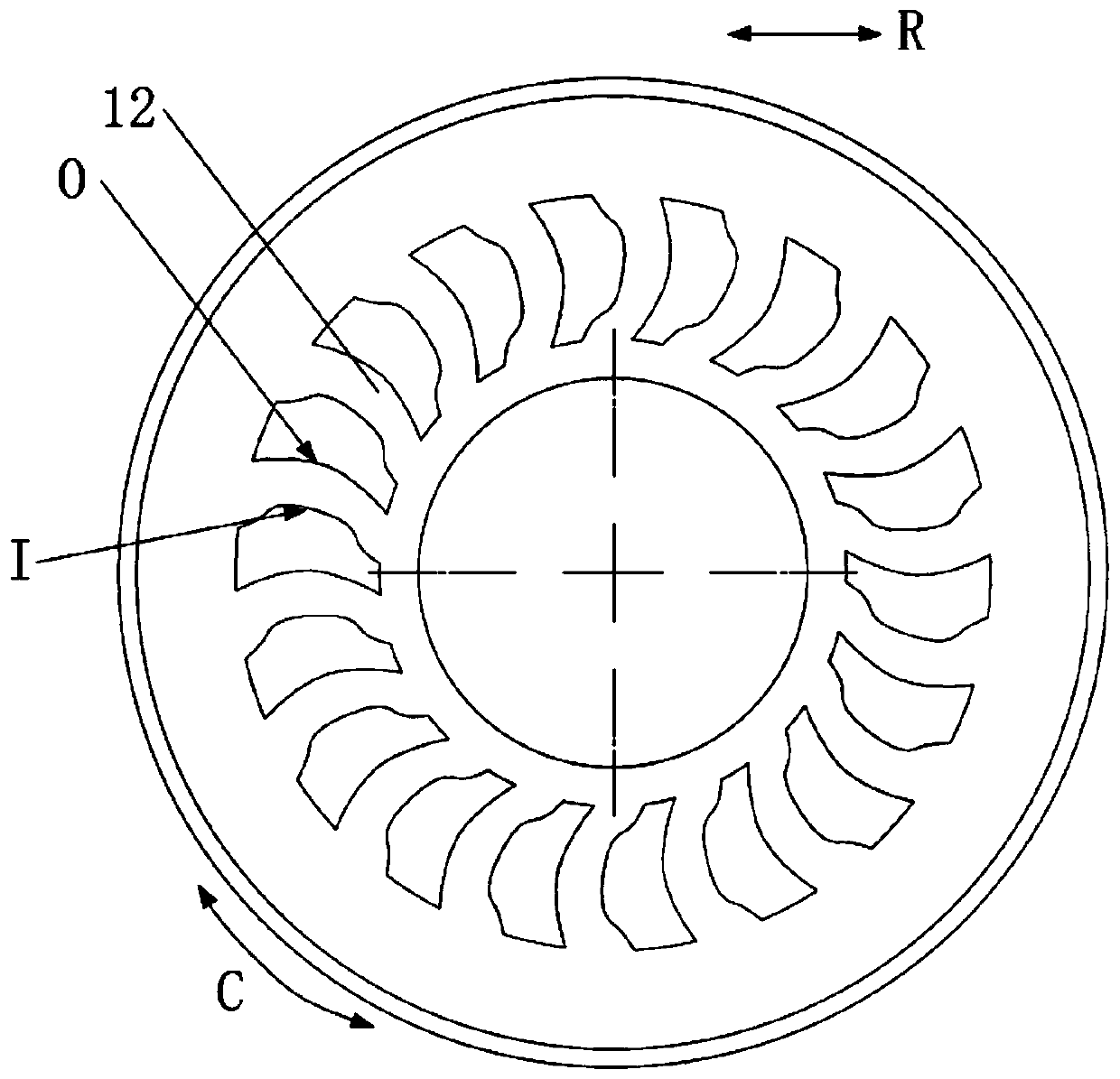

[0042] like Figure 1 to Figure 8 As shown, the present invention proposes a shock-absorbing silent wheel (hereinafter sometimes referred to as tire), the tire includes a rim 1 and a hub 2, the rim 1 and the hub 2 are annular, the rim 1 and the hub 2 are fixed together, and the rim 1 is located on the radially outer side of the hub 2, for example, the rim 1 and the hub 2 can be connected together by clamping, bonding, two-color injection molding or secondary injection molding.

[0043] The present invention also proposes a movable device. One or more shock-absorbing and silent wheels are installed on the bottom of the movable device, and the shock-absorbing and silent wheels are installed on the movable device in a manner that the hub 2 is mounted on a shaft. The shock-absorbing silent wheels can make the mobile equipment generate less vibration and noise when moving on the ground. The weight of the movable equipment is relatively light. For example, the movable equipment can...

no. 2 approach

[0072] The overall structure of the shock-absorbing and silent wheel of the second embodiment is similar to that of the first embodiment. In the second embodiment, the same or similar structures as the first embodiment use the same reference numerals, and no Detailed Description.

[0073] like Figure 9 As shown, the shock-absorbing and silent wheel includes a rim 1 , a hub 2 and a tread 3 , and the tread 3 is connected to the radially outer side of the outer layer 11 . Tread 3 is the part in contact with the ground of the shock-absorbing silent wheel as the outermost layer of the shock-absorbing silent wheel. The tread 3 may be formed by injection molding, pouring or molding processes. The tread 3 is made of elastic material, which can be cast polyurethane, thermoplastic elastomer or vulcanized rubber. The tread 3 can be made of an elastic material whose stress (elastic modulus) at 10% elongation is less than or equal to 60 Mpa, for example, a material with an elastic modu...

no. 3 approach

[0097] The overall structure of the vibration-absorbing and silent wheel of the third embodiment is similar to that of the first embodiment. In the third embodiment, the same or similar structures as those of the first embodiment use the same reference numerals, and are not carried out. Detailed Description.

[0098] like Figure 13 As shown, the outer layer 11 is provided with a reinforcing piece 14, the reinforcing piece 14 is annular, and the radial dimension of the reinforcing piece 14 can be 0.5 mm to 5 mm. The reinforcing member 14 can be made of stainless steel, and the stress of the banner 12 can be reduced through the traction effect on the banner 12, thereby increasing the service life of the tire.

[0099] The material forming the reinforcement 14 is made of a material with an elastic modulus of 500 Mpa or higher, preferably a material with an elastic modulus of 2000 Mpa or higher, such as metal (including alloys) or plastic. If the reinforcement 14 is made of met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com