High-precision grabbing equipment based on electrical control

A technology of electrical control and electrical controller, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of position positioning that cannot be grasped, affects the positioning effect, and is difficult to achieve effective grasping, so as to ensure position accuracy and guarantee The effect of accuracy and high-precision grabbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

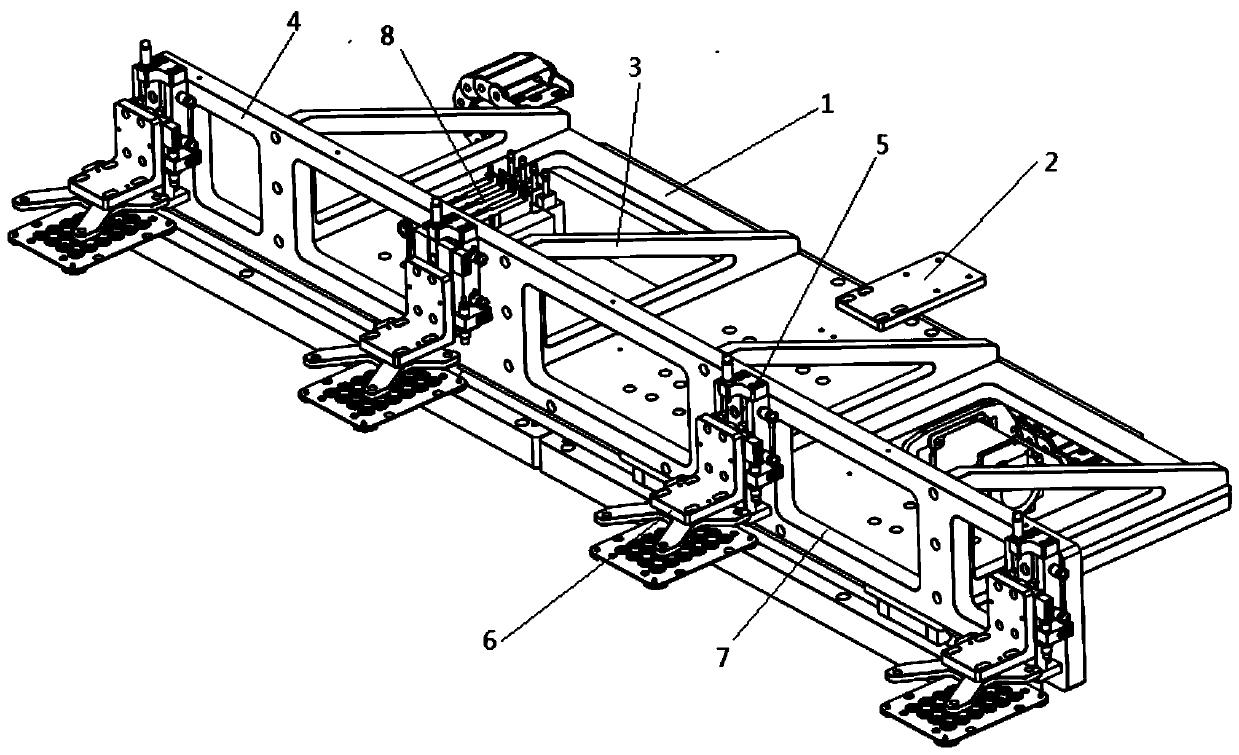

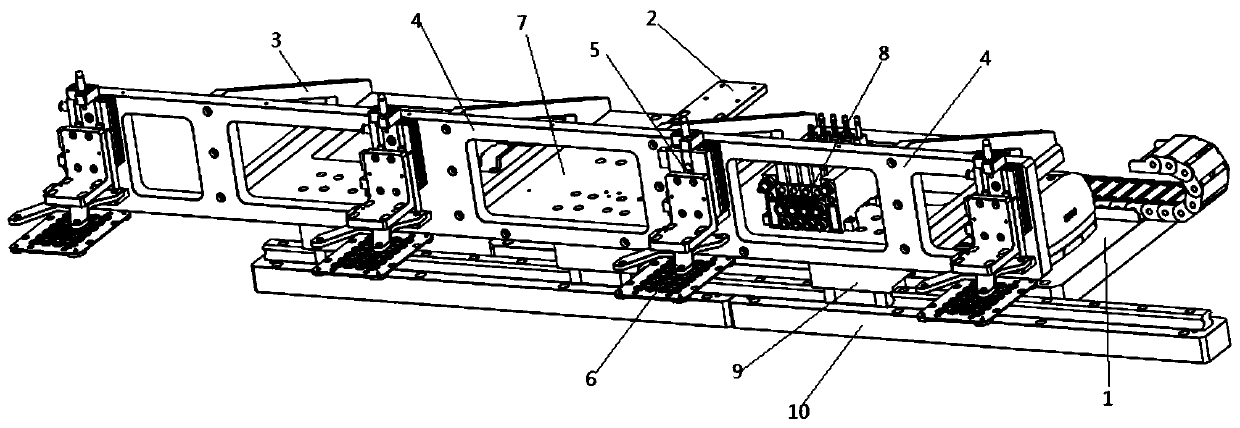

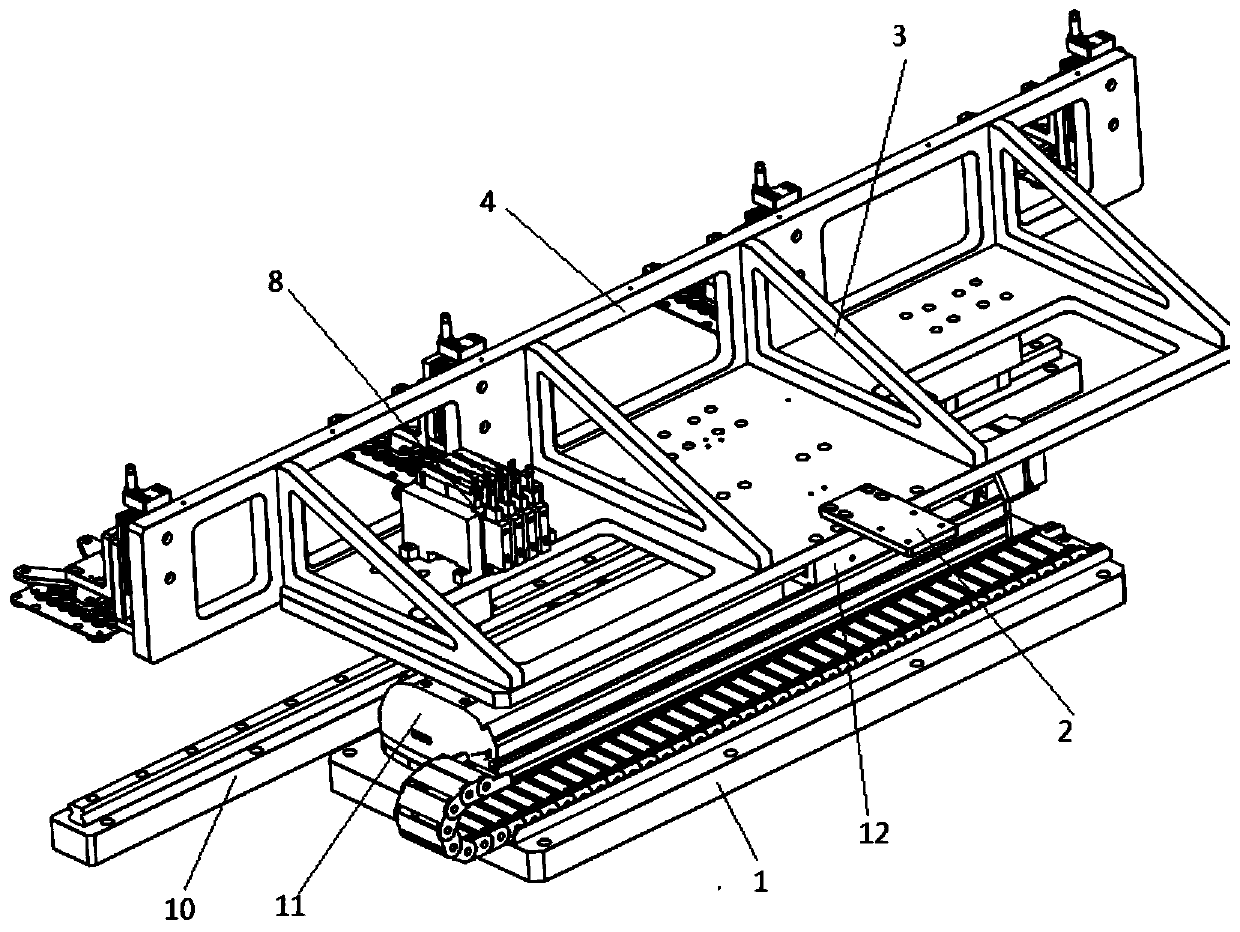

[0022] see Figure 1~5 , in an embodiment of the present invention, a high-precision gripping device based on electrical control, which includes a positioning mounting plate 1, a lateral movement slide 4, a lateral movement mechanism, a gripping drive mechanism 5 and a precision gripping mechanism 6, wherein, The length extension direction of the positioning mounting plate 1 is provided with the laterally moving sliding seat 4 driven by the laterally moving mechanism to move laterally, and the upper part of the laterally moving sliding seat is provided with multiple groups of clips arranged at intervals in succession. Take the drive mechanism 5, the clamping drive mechanism 5 drives the precision grasping mechanism 6 to realize the grasping of the object, it is characterized in that the precision grasping mechanism 6 includes a fixed splint 13 and a movable jaw 14, the The movable jaw 14 is arranged opposite to the fixed splint 13, and the movable jaw adopts an attitude adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com