Trailed straw collection crushing baler

A traction-type, baler technology, which is applied in the field of traction-type straw collection, crushing and baling machines, can solve the problems of large operating change radius and long main machine, and achieve the effect of smooth and smooth operation of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

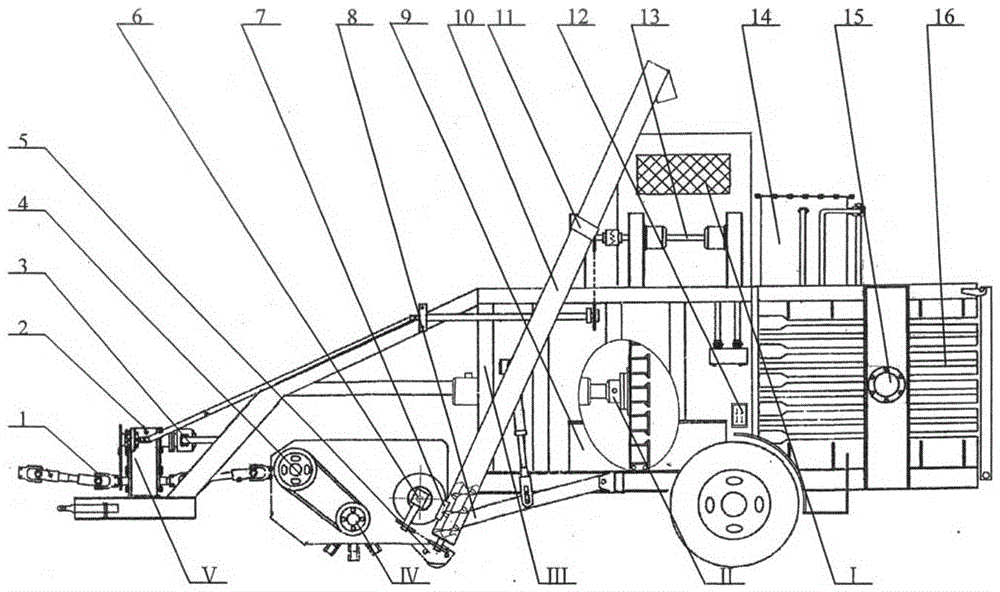

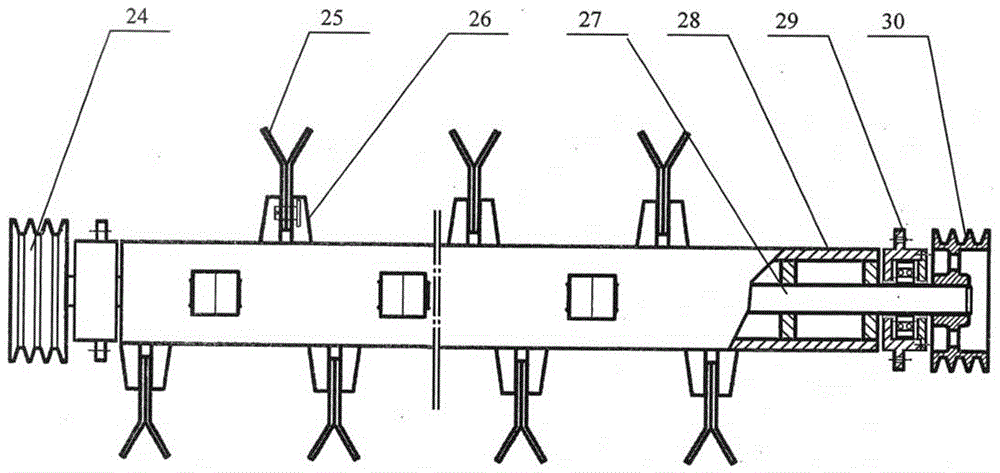

[0054] as attached figure 1 As shown, the traction-type straw collection, crushing and bundling machine designed by the patent research of the present invention includes the whole machine frame III, the collecting and crushing conveying device IV, the crushing straw packing device I, the straw compacting and bundling device II, the power transmission System V.

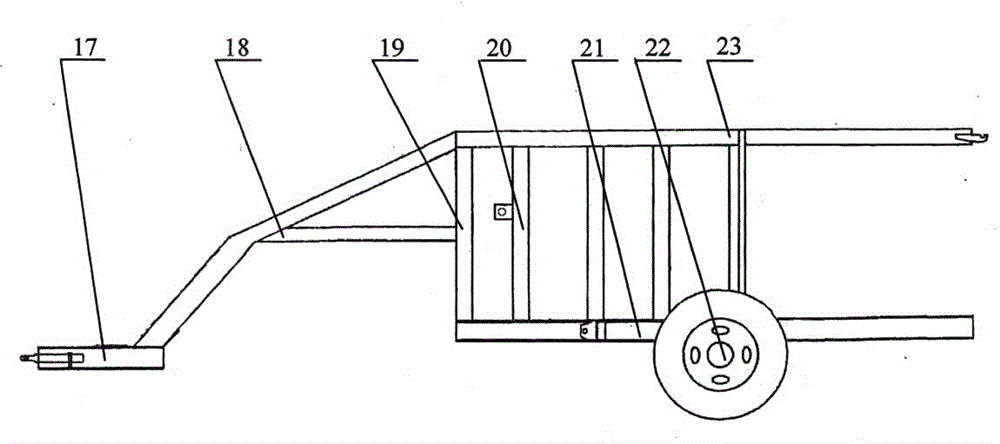

[0055] as attached figure 1 , attached figure 2 As shown, the complete machine frame III includes a main frame 19, a traction frame 18, and road wheels 22. The main machine frame 19 is composed of a bottom beam 69 and a crossbeam to form a chassis 21, a top beam 59 and a crossbeam to form a top frame 23, and a frame structure is formed by columns 20 on both sides. The above beams and columns are all made of carbon steel profiles Manufactured, welded and fixed into a rigid whole in the form of a frame structure by a fully constrained welding method. The traction frame 18 is composed of a traction connection platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com