Pumping unit wellhead polished rod sealing device

A technology for pumping wells and sealing devices, which is applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc. It can solve problems such as poor sealing of wellhead eccentric wear, misalignment of wellhead, aging and sealing of polished rods, etc., to achieve The effect of increasing shrinkage and swelling force and increasing sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

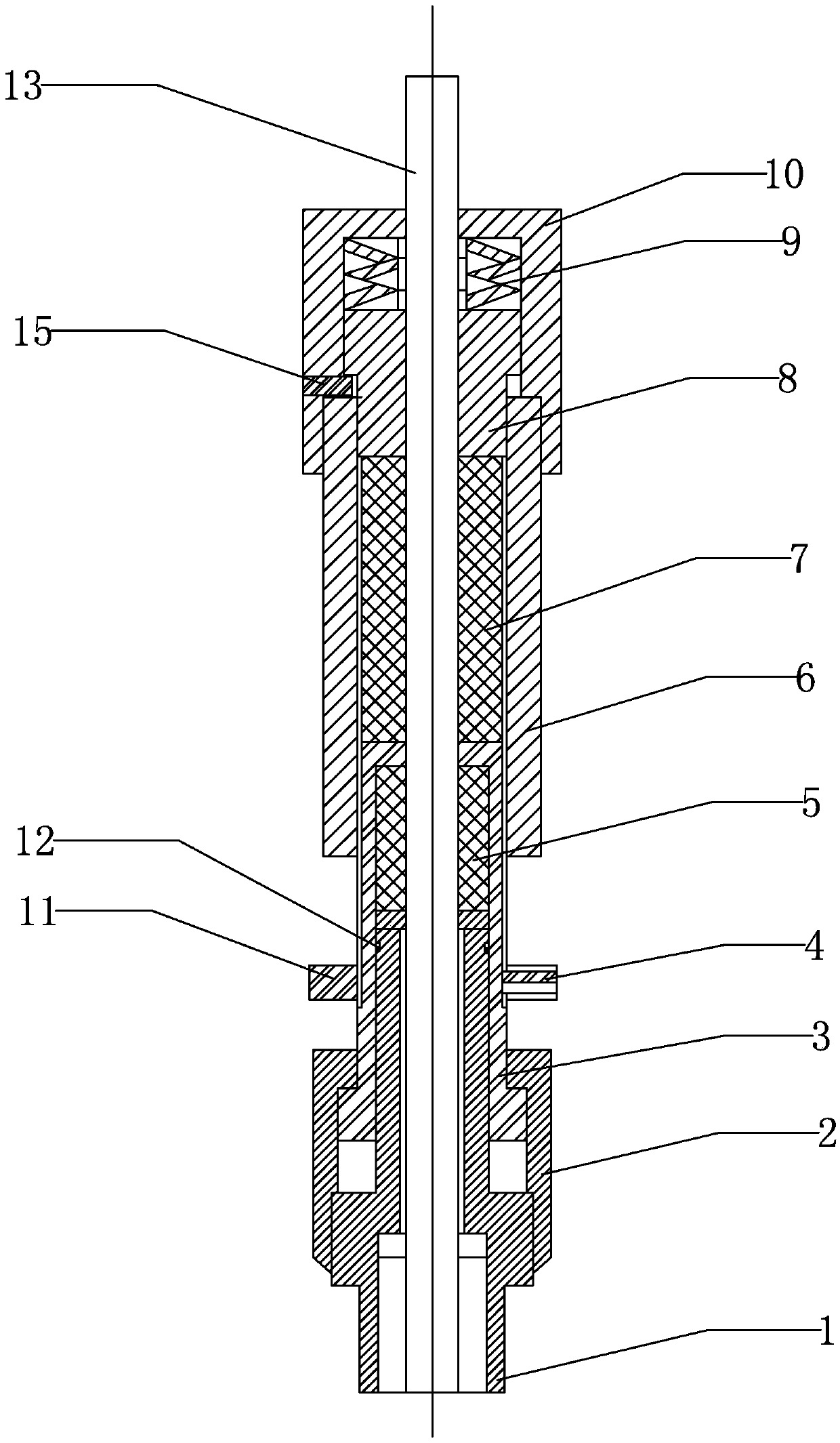

[0026] Some specific embodiments of the present invention will be described in detail below in an exemplary and non-limiting manner with reference to the accompanying drawings. The same reference numerals in the drawings designate the same or similar parts or parts. It should be understood by those skilled in the art that these drawings are not necessarily drawn to scale.

[0027] Such as figure 1 As shown, a kind of pumping unit wellhead polished rod sealing device provided by the invention comprises:

[0028] The upper stuffing box 6 and the lower stuffing box 3 are threaded on the polished rod 13, and the inner side of the lower end of the upper stuffing box 6 is connected with the outer side of the upper end of the lower stuffing box 3 through threads;

[0029] The upper packing 7 and the lower packing 5 are respectively filled in the space between the upper stuffing box 6 and the lower stuffing box 3 and the polished rod 13. root 5 separated;

[0030] Pressure cap 10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com