A special manual grinding equipment for packaging design

An equipment and manual technology, applied in metal processing equipment, grinding/polishing equipment, machine tools suitable for grinding workpiece planes, etc., can solve the problems of low grinding efficiency, time-consuming and laborious, etc. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

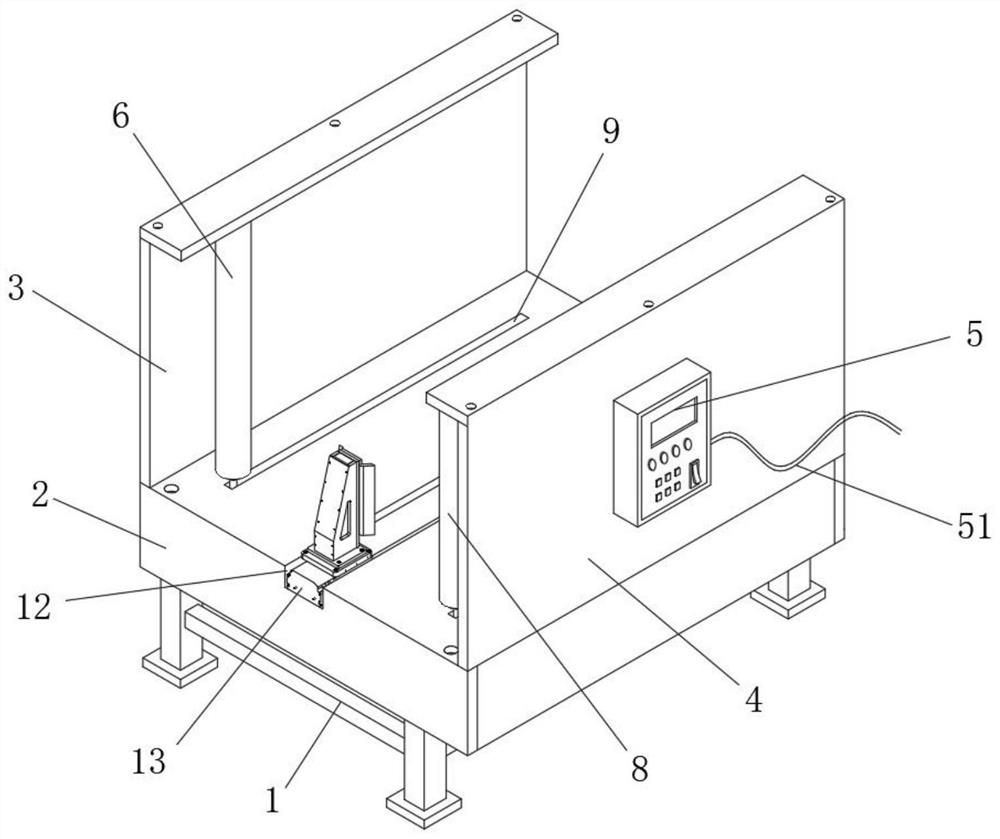

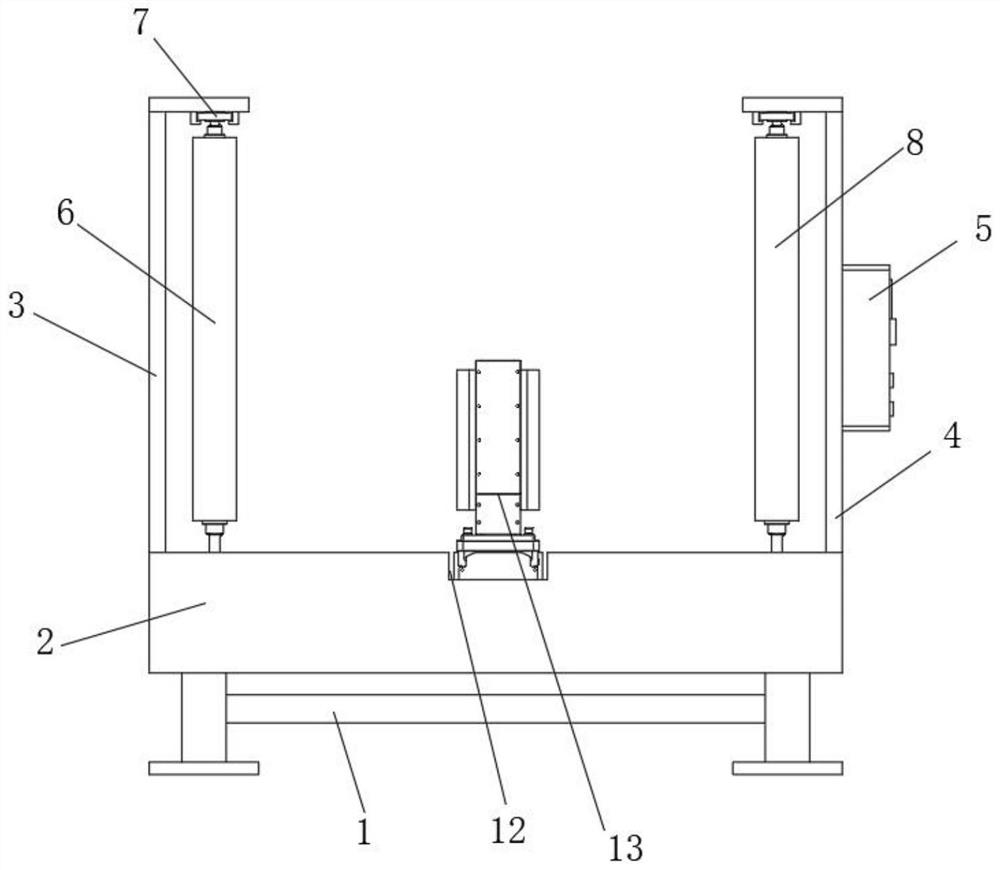

[0033] see Figure 1-2As shown, the present invention provides a special manual grinding equipment for packaging design through improvement, including a support chassis 1, a grinding platform 2, a left baffle 3, a right baffle 4, a control box 5, a power cord 51, a left grinding Roller 6, guide pulley 7, right grinding roller 8, transverse channel 9, synchronous pushing device 10, synchronous transmission mechanism 11, installation groove 12 and product clamping mechanism 13, the bottom of grinding platform 2 is equipped with support chassis 1, by The supporting chassis 1 is supported, and the left baffle 3 and the right baffle 4 are symmetrically installed on the left and right sides of the upper end of the grinding platform 2, which can be produced when the left baffle 3 and the right baffle 4 are grinding the left grinding roller 6 and the right grinding roller 8 The debris is blocked, and the control box 5 is installed in the middle of the outer side of the right baffle 4,...

Embodiment 2

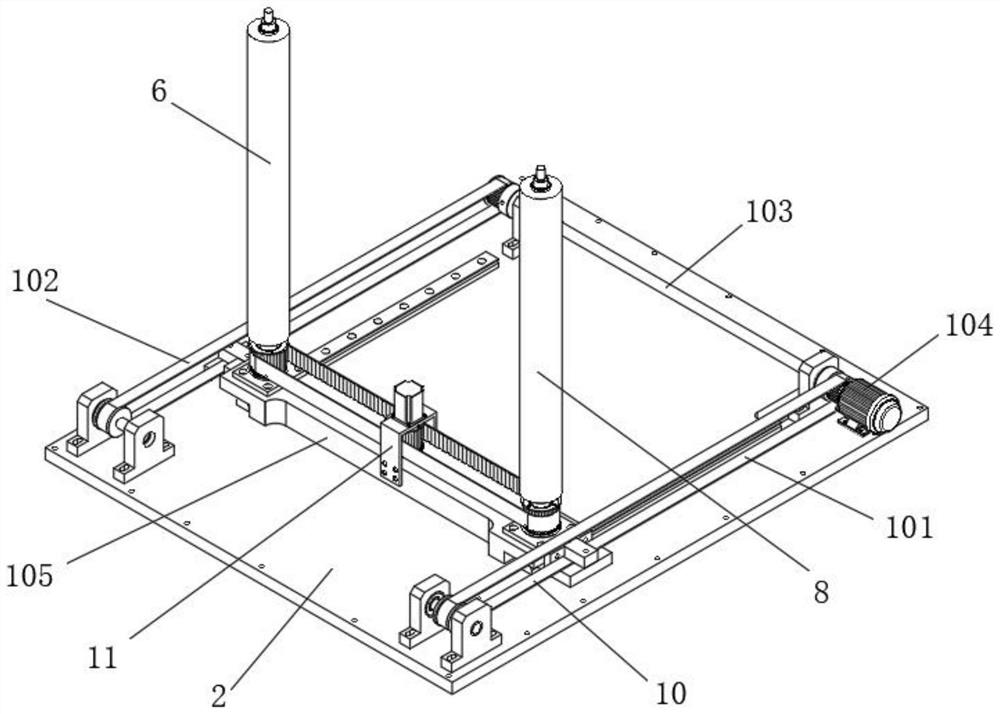

[0039] The present invention provides a special manual grinding equipment for packaging design through improvement. The shafts at the bottom of the left grinding roller 6 and the right grinding roller 8 are all connected to the connecting synchronous transmission mechanism 11, so that after the connecting synchronous transmission mechanism 11 is driven, At the same time, the left grinding roller 6 and the right grinding roller 8 are driven to rotate in the same direction. There are two positioning sliders 107, which are respectively arranged on the inner side of the first pushing mechanism 101 and the second pushing mechanism 102. The two positioning slide rails are provided. 107, slidingly cooperates with the sliders on the left and right sides of the bottom of the push plate 105, so that the position of the push plate 105 is kept constant when the push plate 105 moves, and accurate pushing is realized. Runner 1011 realizes synchronous transmission.

[0040] The present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com