Driving method and driving circuit of liquid crystal display panel and display device

A technology of a liquid crystal display panel and a driving method, which is applied in the field of a driving circuit and a display device, and a driving method of a liquid crystal display panel, and can solve the problems of long charging and discharging time for the voltage change of a liquid crystal capacitor plate, high dynamic power consumption of a circuit system, and color loss of a display panel. Low gamut and other issues, to achieve the effect of improving charging quality, increasing lighting time, and improving color gamut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0027] The demand for transparent display in the market has always been relatively strong, and the color gamut of the liquid crystal display panel in the transparent display mode is relatively low, and the display mode of FSC (Field-Sequential Color, Field-Sequential Color) is adopted.

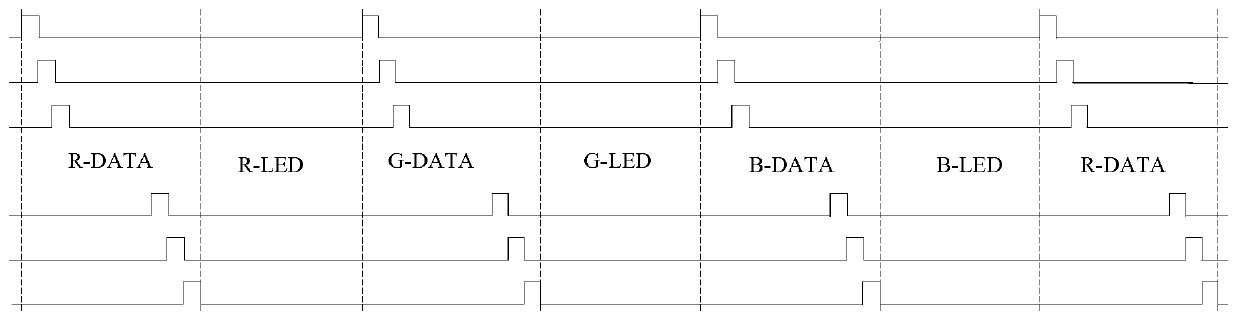

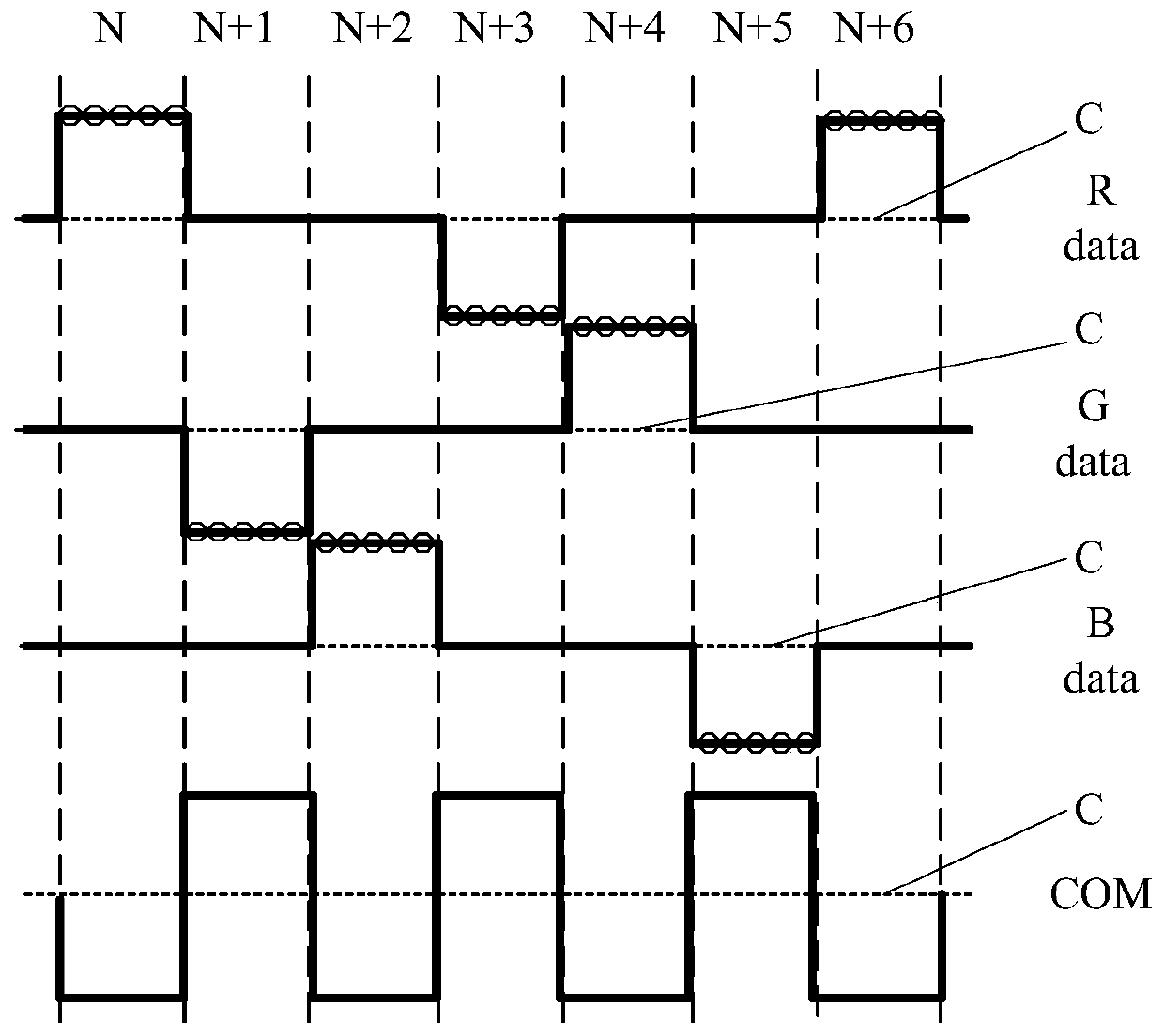

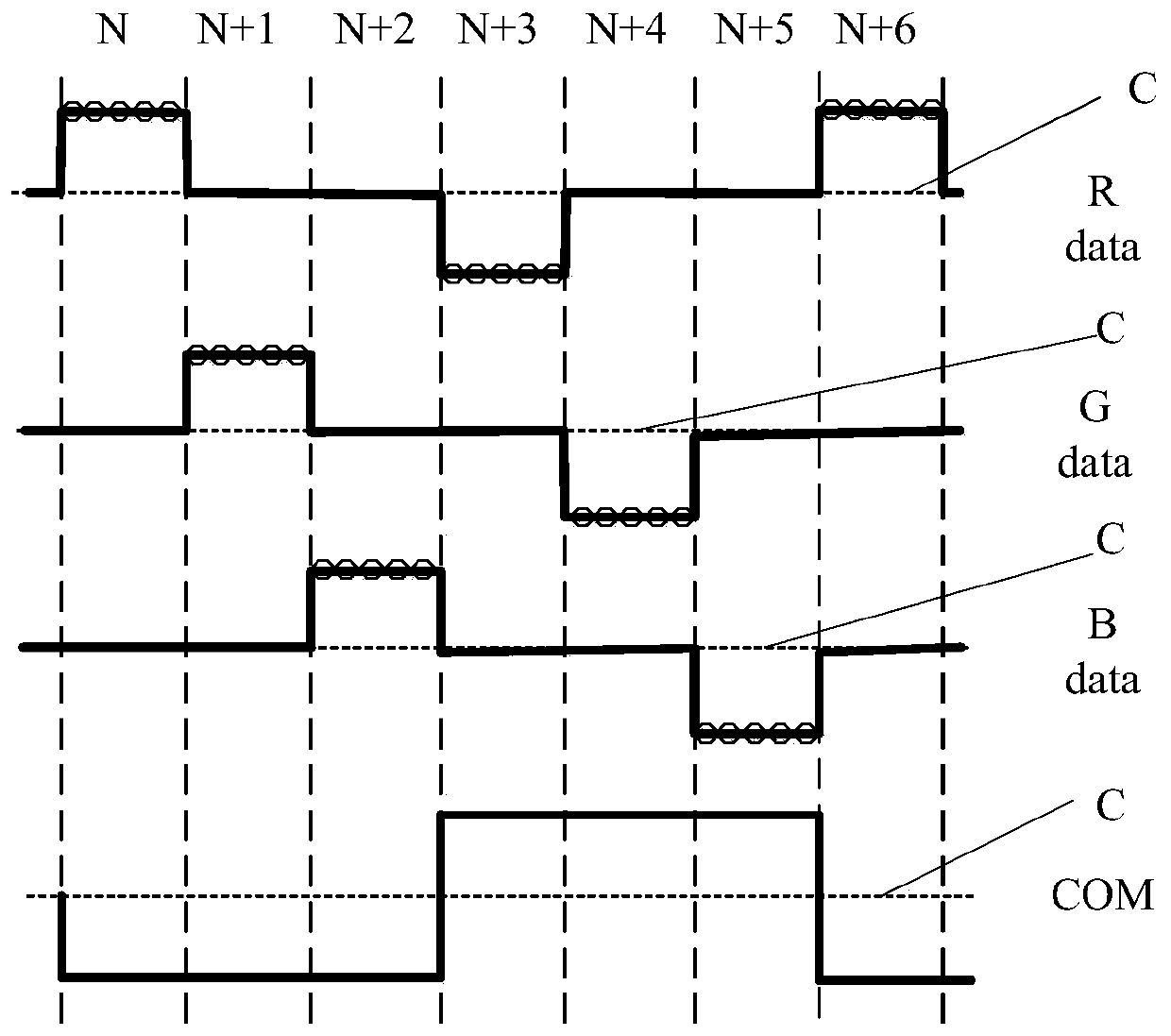

[0028] When the liquid crystal display panel in the transparent display mode includes red (R), green (G), and blue (B) three-color pixels, the timing diagram of the FSC display mode is as follows figure 1 As shown, the display time of each color picture includes three frames, and the data of three colors are sequentially written in the three frames, and each frame includes the data refresh writing phase (R-DATA, B-DATA, G-DATA) and In the backlight lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com