Aircraft active load reduction structure based on cavitator

A technology of active load reduction and aircraft, applied in the direction of motor vehicles, hydrodynamic characteristics/hydrostatic characteristics, underwater operation equipment, etc., can solve the problems of unacceptable weight, space, performance cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will now be further described in conjunction with the embodiments and drawings:

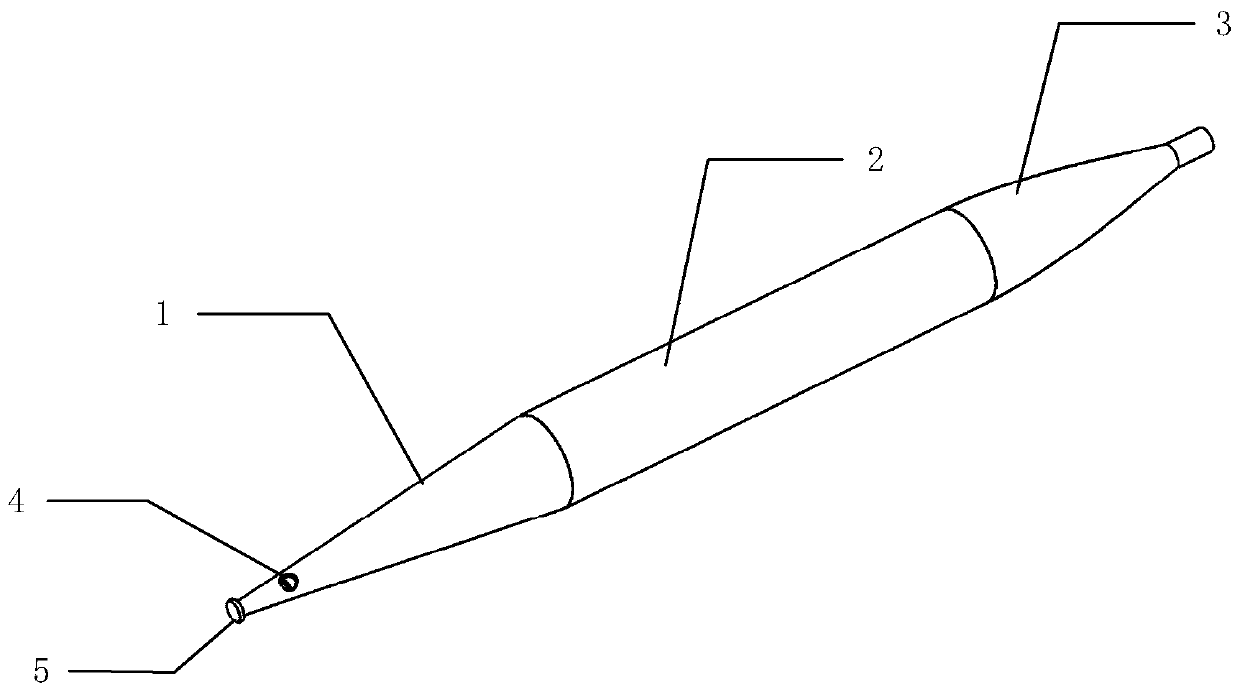

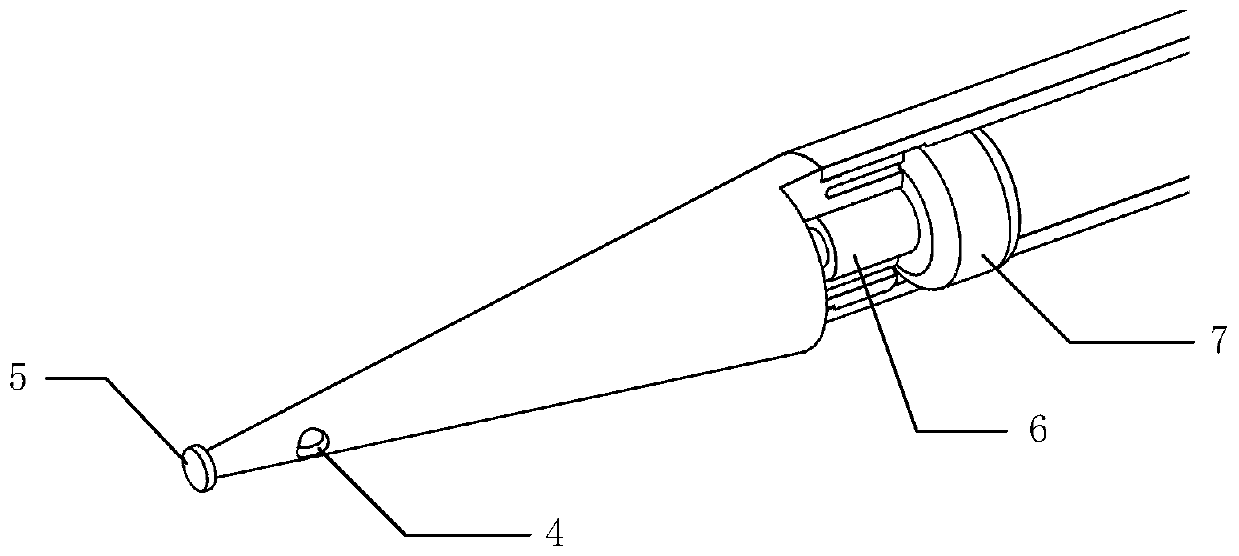

[0019] As attached figure 1 As shown, the application object of the present invention is an underwater vehicle. Generally, the underwater vehicle can be divided into the head of the vehicle 1, the middle section of the vehicle 2, and the tail section of the vehicle 3. In the present invention, an active load reduction system is designed in the head 1 of the aircraft. The active load reduction system includes an air jet hole 4, a cavitation device 5, a jet on-off valve 6 and a high-pressure gas cylinder 7. The active load shedding system occupies a small space and does not have a big impact on other parts in the head of the aircraft. The cavitator 5 is located at the top of the head 1 of the aircraft, and is a disc-shaped structure with an acute edge. Its function is to guide the area behind the cavitator to form a smooth and smooth package cavity. The supercavitation g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com