Rail butt joint connecting plate

A technology of butt joints and connecting plates, which is applied in the direction of tracks, movable tracks, roads, etc., can solve problems such as potential safety hazards, rail jamming, and obstacles to the passage of claws, so as to prevent derailment accidents, prevent loosening, and increase strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

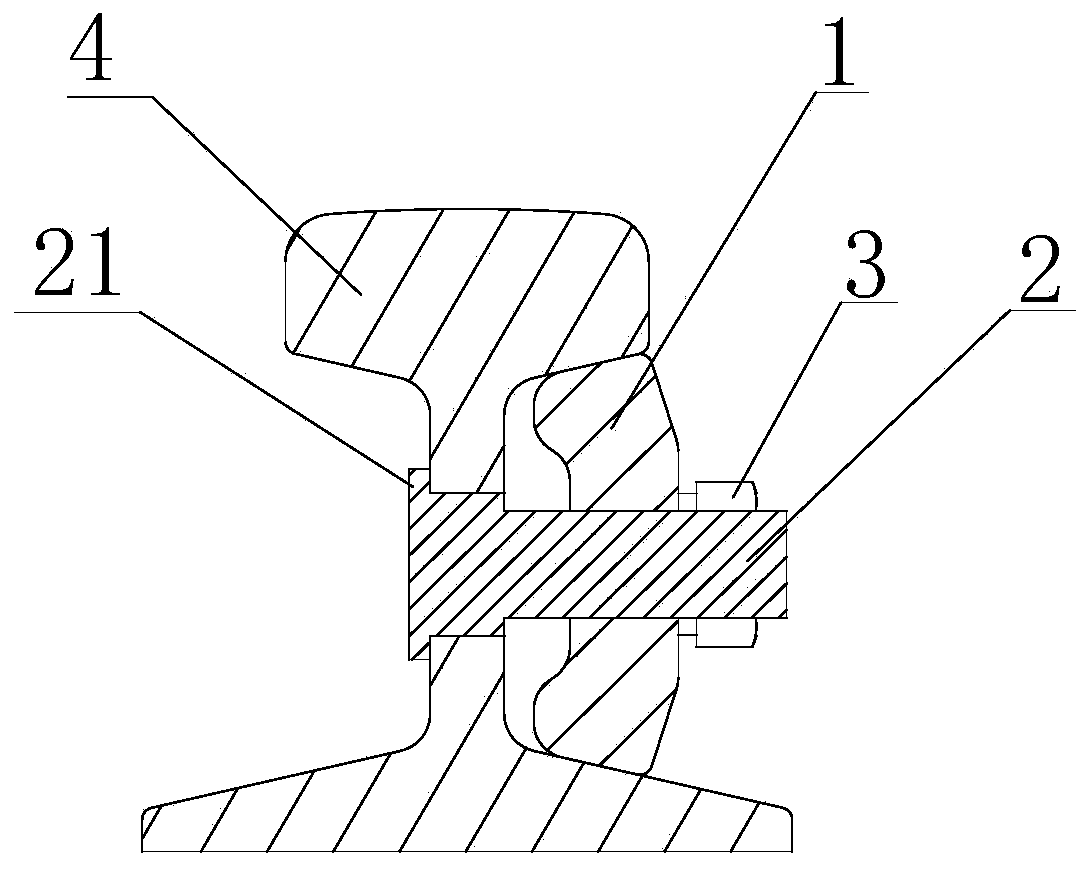

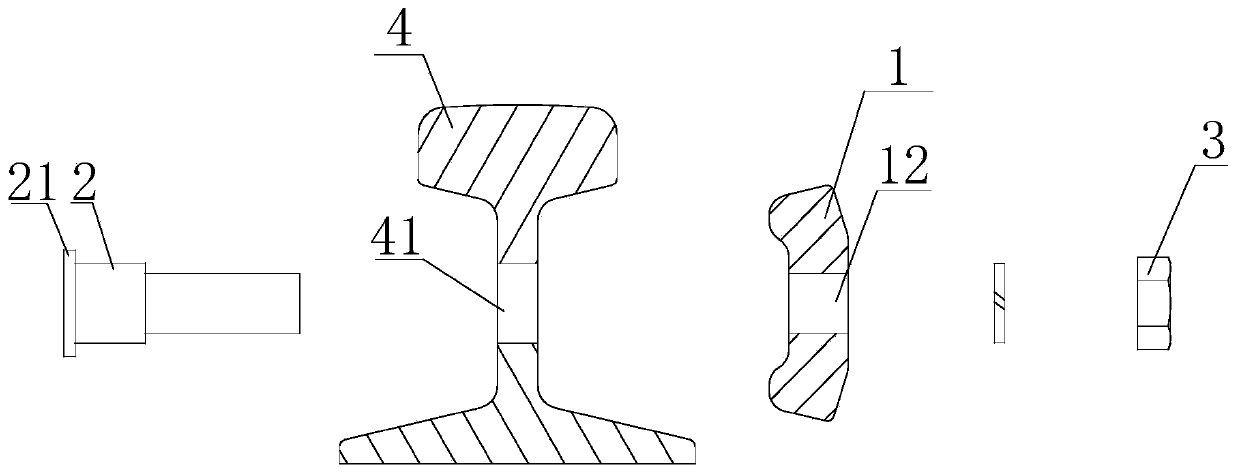

[0013] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a rail butt joint connecting plate has a track bolt hole 41 at the butt joint of the track 4, and is characterized in that: a connecting plate 1 is installed at the inner rail waist of the butt joint of the track 4, and the connecting plate 1 is provided with a connecting plate bolt hole 11, and the bolt 2 passes through the track bolt hole 41 at the butt joint of the track 4 from the outer rail waist of the track 4, and the connecting plate bolt hole 11 is tightened and fixed with a nut 3, and the bolt 2 A flange 21 is arranged on the outside of the screw head, and the flange 21 is close to the outer rail waist of the track 4 .

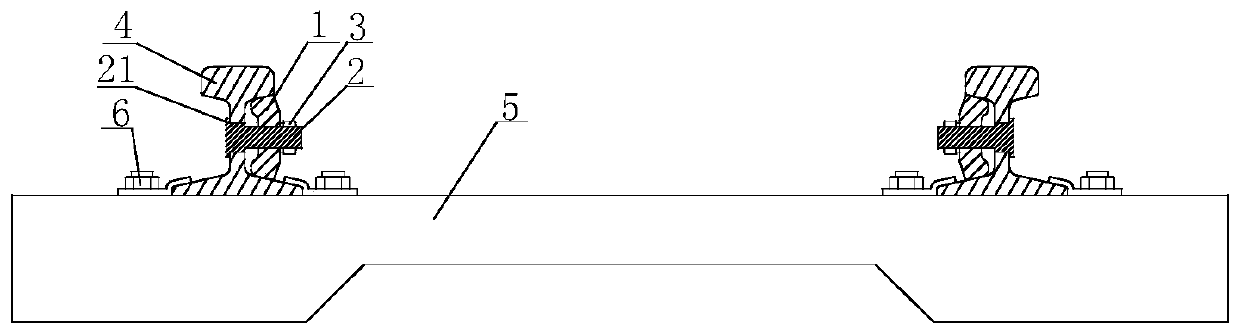

[0014] like Image 6 , Figure 7 As shown, the track 4 is installed on the sleeper 5 through the fixed plate 6, and the track butt joint connecting plate is installed at the butt joint of the track 4. The braking device of the shuttle car 7 includes a claw 8 and a bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com