A core-shell fiber structure electrode and its preparation method and application

A technology of core-shell structure and fiber structure, which is applied in the field of new core-shell structure electrode and its preparation, to achieve the effects of small electrode ohmic polarization loss, strong practicability, and high ion transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

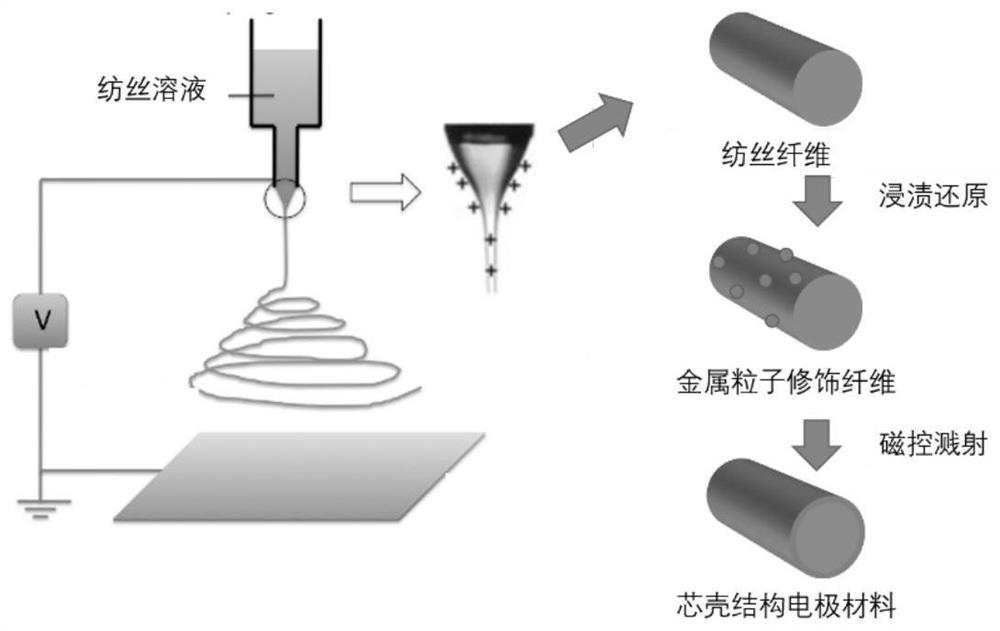

Method used

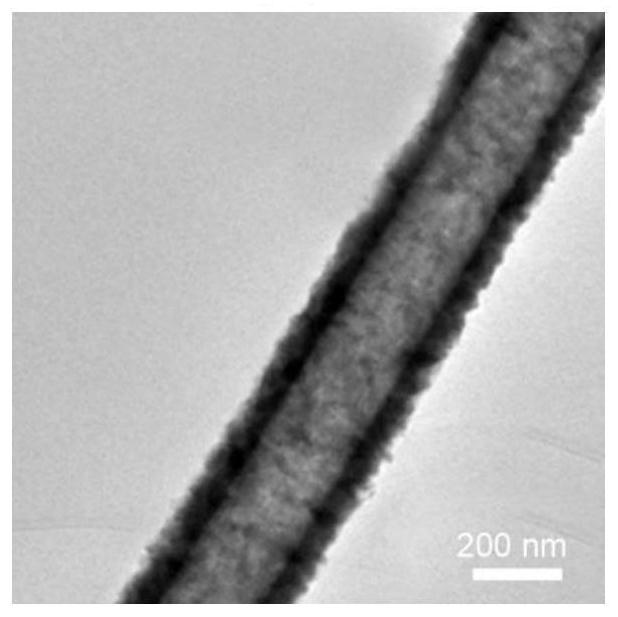

Image

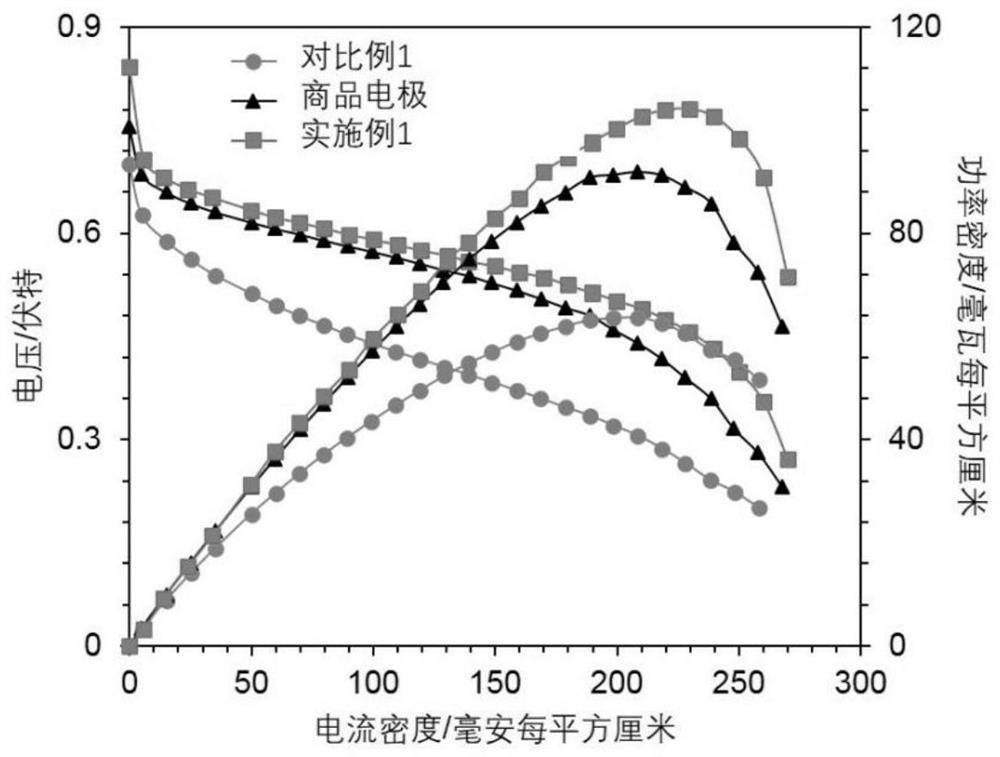

Examples

Embodiment 1

[0033] a. Preparation of nuclear layer material spinning solution

[0034] Dissolve a certain mass of perfluorosulfonic acid polyions in a mixed solvent of water and methanol with a volume ratio of 1:1, with a mass concentration of 5%, then add polyacrylic acid, with a mass concentration of 5%, and stir for 12 hours at room temperature , ready to use after fully dissolving evenly.

[0035] b. Electrospinning preparation of core layer structure

[0036] The spinning solution prepared in the above step a was placed in the spinning injection device, the feed rate was 2mL / min, the distance between the needle and the receiver was 10cm, the spinning potential was 20kV, the controlled ambient temperature was 25 degrees Celsius, and the humidity was 50%. The prepared fiber structure material is ready for use.

[0037] c. Magnetron sputtering preparation of shell structure

[0038] Add a certain mass of chloroplatinic acid into a mixed solvent with a volume ratio of deionized water ...

Embodiment 2

[0057] a. Preparation of nuclear layer material spinning solution

[0058] Dissolve a certain amount of polybenzimidazole in dimethylformamide with a mass concentration of 10%, then add it into polyvinylpyrrolidone with a mass concentration of 6%, stir for 48 hours at 50°C, and wait until fully dissolved and uniform use.

[0059] b. Electrospinning preparation of core layer structure

[0060] The spinning solution prepared in the above step a was placed in the spinning injection device, the feed rate was 0.5mL / min, the distance between the needle and the receiver was 5cm, the spinning potential was 10kV, the controlled ambient temperature was 40 degrees Celsius, and the humidity was 80%. The prepared fiber structure material is ready for use.

[0061] c. Magnetron sputtering preparation of shell structure

[0062] Mix a certain quality of chloroplatinic acid and nickel nitrate according to the ratio of the amount of substances to 1:1, add water and methanol to a mixed solve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com