Electrode material with fiber structure and preparation and application

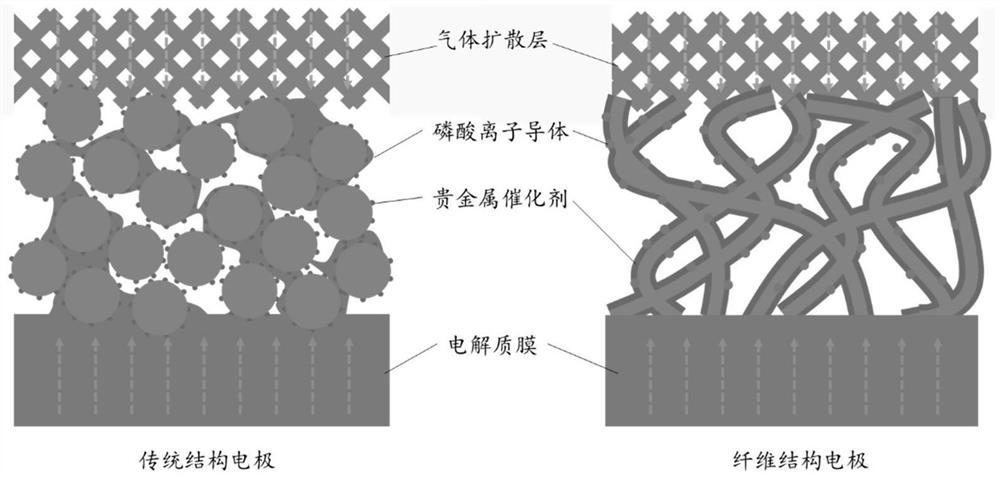

A technology of electrode material and fiber structure, which is applied in the field of new composite fiber structure electrodes and its preparation, can solve the problems of difficult to achieve electrode performance, uncontrollable porosity, pore size and channel shape, and difficult to achieve in-depth research on electrode performance. High utilization rate, increased porosity, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

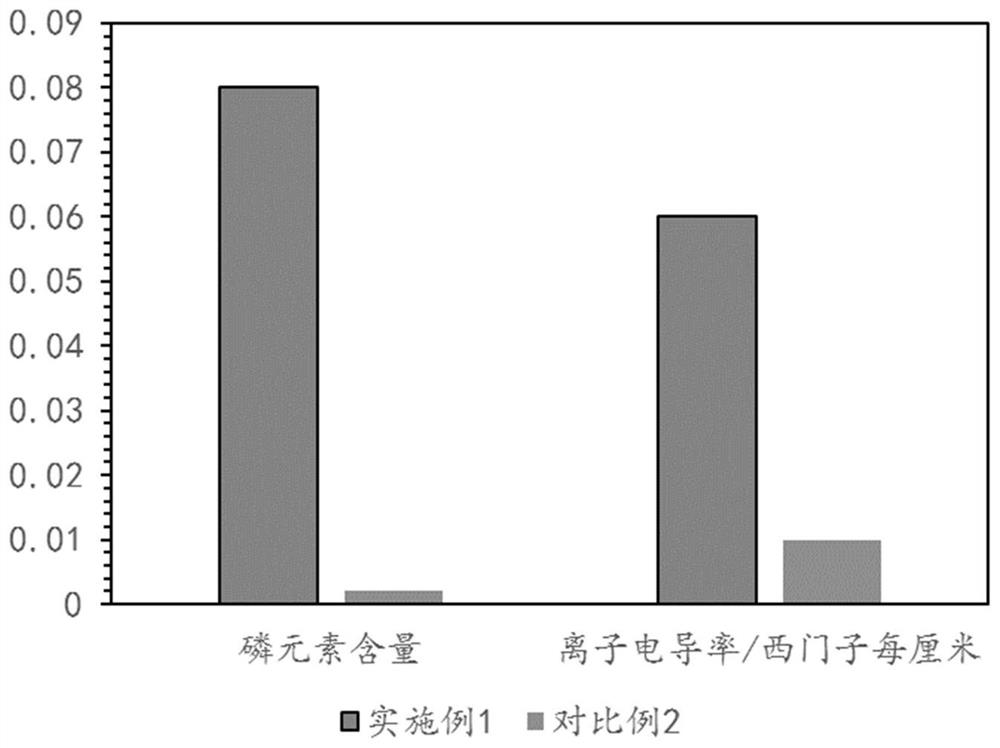

Embodiment 1

[0037] a. Preparation of composite spinning solution

[0038] A certain mass of chloroplatinic acid was added into the dimethylformamide solvent so that the mass concentration of the precious metal was 5%, and it was fully dissolved for later use. A certain mass of perfluorophosphate polyion was added to the above solution to make the mass concentration 0.5%, and stirred for 2 hours. A certain mass of polyacrylic acid was added to the above solution to make the mass concentration 5%, and stirred for 2 hours at room temperature, fully dissolved and uniform before use.

[0039] The above composite solution was heated to 120° C. in an oil bath under continuous stirring, continued to react for 4 hours, cooled to room temperature, and continued to stir for 1 hour before use.

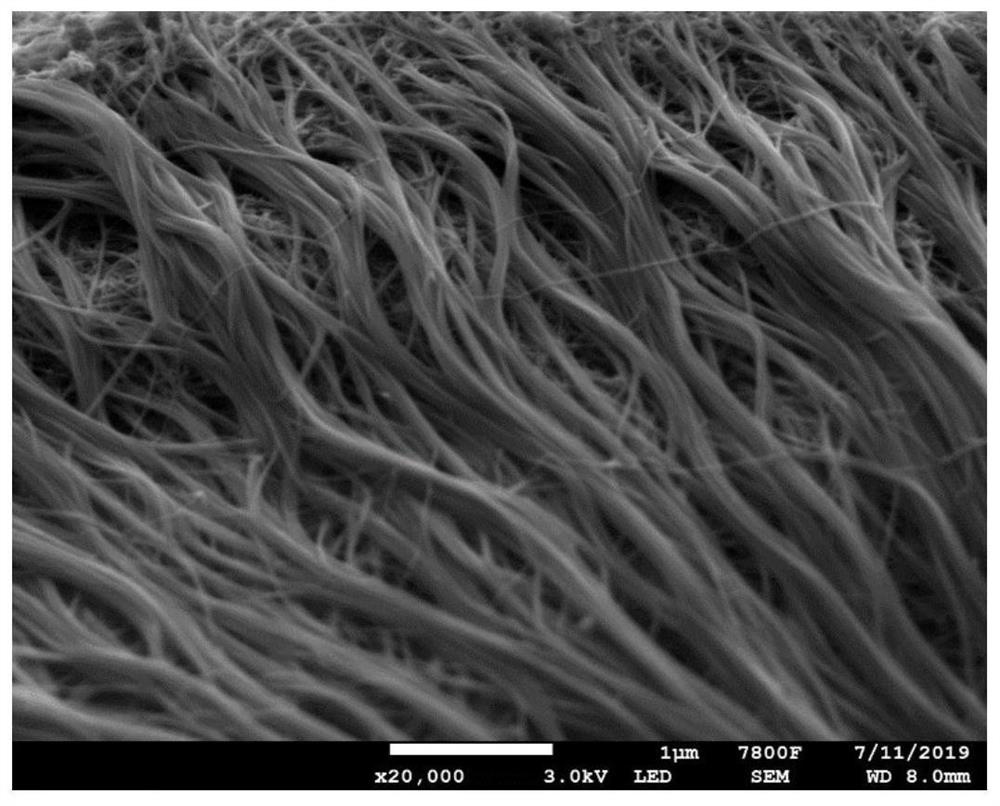

[0040] b. Electrospinning preparation of fiber-structured electrode materials

[0041] Place the spinning colloid solution prepared in the above step a at the inlet of the spinning injection device, the feed ...

Embodiment 2

[0055] a. Preparation of composite spinning solution

[0056] A certain mass of chloroplatinic acid and cobalt nitrate was added to the dimethylformamide solvent, so that the mass concentration of the noble metal was 5%, and the molar ratio of the noble metal to cobalt was 5:1, fully dissolved for later use. A certain mass of perfluorophosphate polyion was added to the above solution to make the mass concentration 0.5%, and stirred for 2 hours. A certain mass of polyacrylic acid was added to the above solution to make the mass concentration 5%, and stirred for 2 hours at room temperature, fully dissolved and uniform before use.

[0057] The above composite solution was heated to 120° C. in an oil bath under continuous stirring, continued to react for 4 hours, cooled to room temperature, and continued to stir for 1 hour before use.

[0058] b. Electrospinning preparation of fiber-structured electrode materials

[0059] Place the spinning colloid solution prepared in the above...

Embodiment 3

[0062] a. Preparation of composite spinning solution

[0063] Add a certain mass of chloroplatinic acid and nickel nitrate into the dimethylformamide solvent so that the mass concentration of the noble metal is 5%, and the molar ratio of the noble metal to cobalt is 3:1, fully dissolved and then used. A certain mass of phosphonic acid subunit polycarboxylic acid was added to the above solution to make the mass concentration 0.5%, and stirred for 2 hours. A certain mass of polyacrylic acid was added to the above solution to make the mass concentration 5%, and stirred for 2 hours at room temperature, fully dissolved and uniform before use.

[0064] The above composite solution was heated to 120° C. in an oil bath under continuous stirring, continued to react for 4 hours, cooled to room temperature, and continued to stir for 1 hour before use.

[0065] b. Electrospinning preparation of fiber-structured electrode materials

[0066] Place the spinning colloid solution prepared in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com